Film coating agent for wound surface treatment and preparation method of film coating agent

A film coating agent and wound surface technology, applied in the field of medicine, can solve the problems of poor air permeability of adhesive tape, local skin soaking, poor selectivity, etc., and achieve the effects of good bacteriostatic effect, convenient use and reduction of allergic reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of film coating agent

[0037] (1) Prescription composition:

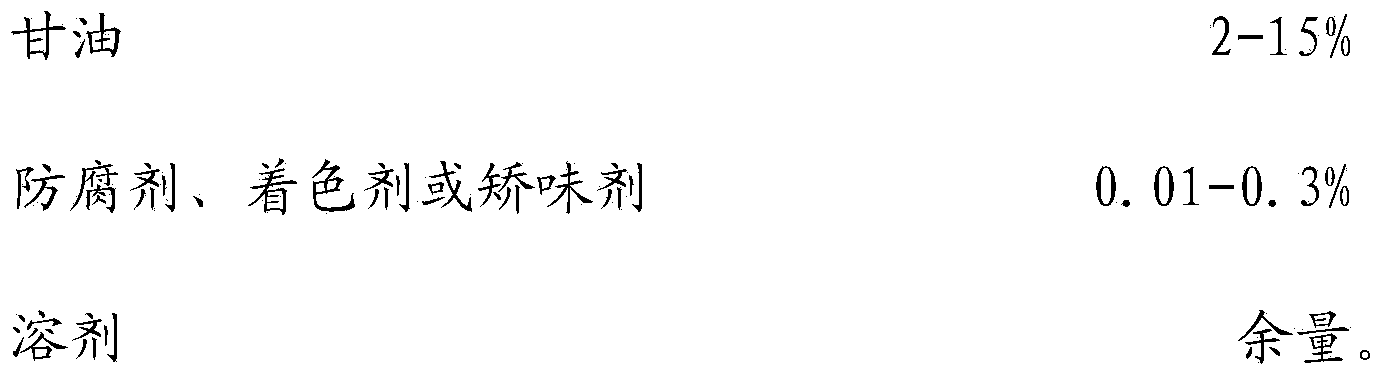

[0038] The prescription composition of table 1 coating agent

[0039]

[0040] In prescriptions 1-5, polyvinyl alcohol 2488 can be replaced by sodium alginate, polyvinyl formal, polyvinyl butyral, carbomer, sodium carboxymethylcellulose and hypromellose . Sodium ethylparaben also includes a reasonable amount of coloring or flavoring.

[0041] (2) The preparation method of the coating agent of prescription one to prescription five:

[0042] 1. Dissolve the prescribed amount of preservative with an appropriate amount of water to prepare solution 1;

[0043] 2. Put the prescribed amount of polyvinyl alcohol 2488 and water-soluble chitosan in a suitable container, add the remaining prescribed amount of distilled water to it, stir and mix evenly while adding, add the prescribed amount of glycerin after swelling for 30 minutes, and gradually heat up While stirring to 80°C, unt...

Embodiment 2

[0046] Embodiment 2: the bacteriostasis experiment of coating agent

[0047] (1) Strain: Staphylococcus aureus CMCC (B) 26003] 4th generation; (Note: provided by Guangdong Microbial Culture Collection Center)

[0048] (2) Preparation of bacteria solution: take the above Staphylococcus aureus and use 0.9% sterile sodium chloride solution to make a bacteria suspension containing 50-100 cfu of bacteria per 1 ml.

[0049] (3) test product test group: get a certain amount of film-coating agent prepared by prescription one to prescription five of embodiment 1 and the above-mentioned bacterial suspension (50~100cfu / ml) of 1ml and inject in the petri dish, pour into nutrient agar culture medium immediately. Prepare 2 flat plates in parallel for each batch of test samples, culture them at 30-35°C for 3 days, and then measure the number of bacteria according to the plate method.

[0050] Viable bacteria group: Take 1ml (50-100cfu / ml) of the above-mentioned bacteria suspension and injec...

Embodiment 3

[0058] Embodiment 3: the preparation of coating agent

[0059] (1) Prescription composition:

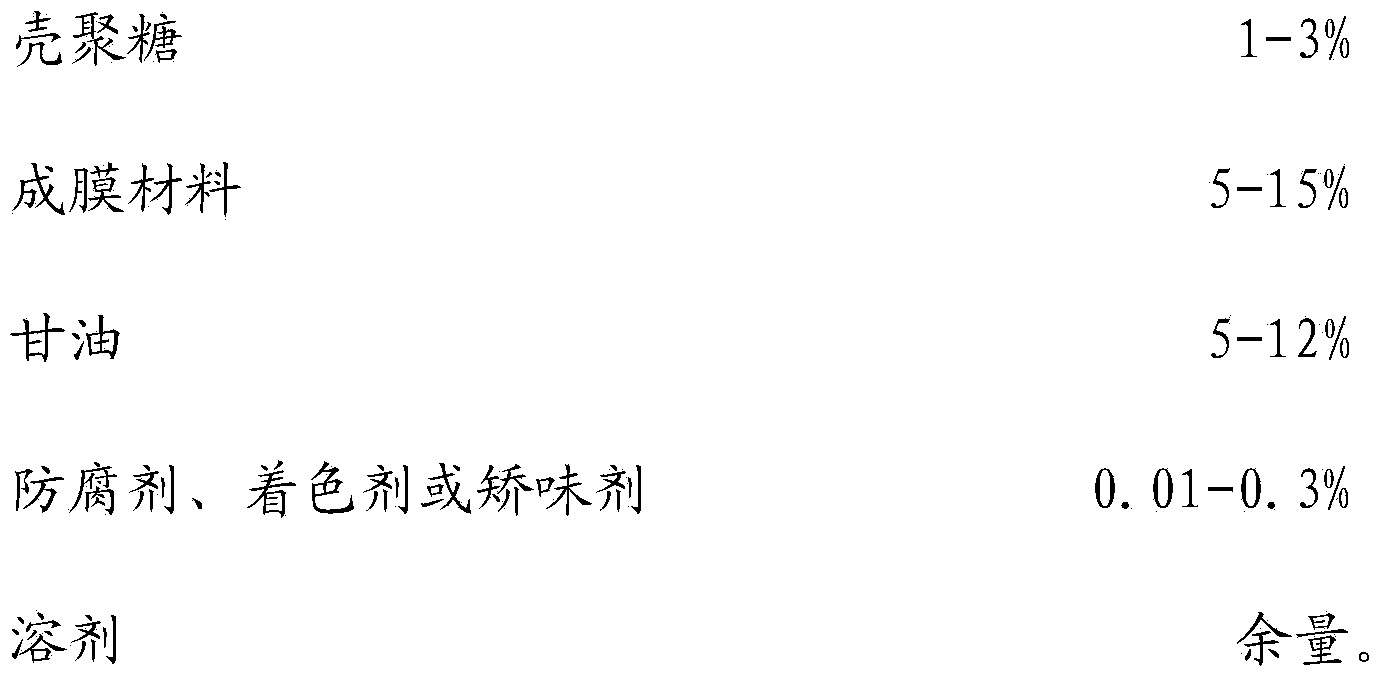

[0060] The prescription composition of table 3 coating agent

[0061]

[0062]

[0063] In prescriptions 6-10, polyvinyl alcohol 2488 can be replaced by sodium alginate, polyvinyl formal, polyvinyl butyral, carbomer, sodium carboxymethylcellulose and hypromellose . Sodium ethylparaben also includes a reasonable amount of coloring or flavoring. The water can be deionized or distilled.

[0064] (2) The preparation method of the coating agent of prescription six to prescription ten:

[0065] 1. Dissolve the prescribed amount of preservative with an appropriate amount of water to prepare solution 1.

[0066] 2. Put the prescribed amount of polyvinyl alcohol 2488 and water-soluble chitosan in a suitable container, add the remaining prescribed amount of water to it, stir and mix evenly while adding, add the prescribed amount of glycerin after swelling for 30 minutes, and gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com