Concrete foamed insulating brick and preparation method thereof

A technology for thermal insulation bricks and concrete, applied in the field of building materials, can solve the problems of high brittleness, poor impact resistance, poor durability, etc., and achieve the effects of high bending strength, good thermal insulation effect, and reliable foaming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

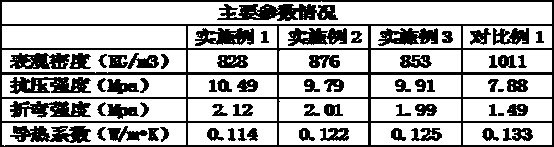

Examples

Embodiment 1

[0019] Example 1: a. Take 47 grams of alkali phenolic waste sand with a particle size of 20-30um, 33 grams of red mud with a particle size of 11-15um, 7 grams of silicon carbide with a particle size of 8-10um, and basalt with a size of 3mm-9mm Add 20 grams of chopped puffed fiber into a horizontal ribbon mixer and mix for 10-15 minutes;

[0020] b. Take 8 grams of polycarboxylate high-efficiency water reducer, 1 gram of potassium sodium tartrate, and 66 grams of water, mix evenly, and add 144 grams of Portland cement into a high-speed mixer, and stir at a speed of 800-1000 rpm 1 to 2 minutes;

[0021] c. Slowly add the mixture in step a to the slurry in step b, and stir at a speed of 600 to 700 rpm for 3 to 5 minutes;

[0022] d. Take 4 grams of protein foaming agent, 2 grams of sodium lauroyl sarcosinate, 1 gram of aluminum triethylphosphate, and 3 grams of gum arabic powder, and add them to a high-speed mixer at 55-60 °C, and mix them at 1000- Stir at a speed of 1200 rpm f...

Embodiment 2

[0026] Example 2: a. Take 44 grams of alkali phenolic waste sand with a particle size of 20-30um, 29 grams of red mud with a particle size of 11-15um, 6 grams of silicon carbide with a particle size of 8-10um, and basalt with a size of 3mm-9mm 17 grams of chopped puffed fiber was added to a horizontal ribbon mixer and mixed for 10 to 15 minutes;

[0027] b. Take 7 grams of polycarboxylate high-efficiency water reducer, 1 gram of potassium sodium tartrate, and 64 grams of water, mix evenly, and add 134 grams of Portland cement into a high-speed mixer, and stir at a speed of 800-1000 rpm 1 to 2 minutes;

[0028] c. Slowly add the mixture in step a to the slurry in step b, and stir at a speed of 600 to 700 rpm for 3 to 5 minutes;

[0029] d. Take 3 grams of protein foaming agent, 1 gram of sodium lauroyl sarcosinate, 1 gram of aluminum triethylphosphate, and 2 grams of gum arabic powder, and add them to a high-speed mixer at 55-60 °C, and mix them at 1000- Stir at a speed of 12...

Embodiment 3

[0033] Example 3: a. Take 51 grams of alkali phenolic waste sand with a particle size of 20-30um, 43 grams of red mud with a particle size of 11-15um, 9 grams of silicon carbide with a particle size of 8-10um, and basalt with a size of 3mm-9mm Add 22 grams of chopped puffed fiber into a horizontal ribbon mixer and mix for 10 to 15 minutes;

[0034] b. Take 11 grams of polycarboxylate superplasticizer, 2 grams of sodium potassium tartrate, and 76 grams of water, mix well, and add 156 grams of 425 Portland cement into a high-speed mixer at a speed of 800-1000 rpm Stir for 1 to 2 minutes;

[0035] c. Slowly add the mixture in step a to the slurry in step b, and stir at a speed of 600 to 700 rpm for 3 to 5 minutes;

[0036] d. Take 5 grams of protein foaming agent, 2 grams of sodium lauroyl sarcosinate, 2 grams of aluminum triethylphosphate, and 3 grams of gum arabic powder, and add them to a high-speed mixer at 55-60 °C, and mix them at 1000-600 °C. Stir at a speed of 1200 rpm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com