Composite concrete water evaporation inhibitor and application method thereof

An evaporation inhibitor and application method technology, applied in the field of concrete, can solve the problems of lack of wind resistance, slow film formation, difficult to clean, etc., to improve high temperature resistance and wind resistance, increase cohesion and strength, and inhibit moisture. Evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A composite concrete moisture evaporation inhibitor, which is composed of octadecyltrimethylammonium bromide and sodium octadecylsulfonate, the molar ratio of the two is 1:1.

[0028]The above composite concrete water evaporation inhibitor is prepared into a single-phase solution, which is applied to control water evaporation in the plastic state of concrete. The mass percent of each component of the prepared single-phase solution is about: 3.04% of the composite concrete moisture evaporation inhibitor described in this embodiment, 45.03% of ethanol, and 51.93% of water.

Embodiment 2

[0033] A composite concrete water evaporation inhibitor, which is composed of octadecyltrimethylammonium bromide and sodium stearate, and the molar ratio of the two is 1:1.

[0034] The above composite concrete water evaporation inhibitor is prepared into a single-phase solution, which is applied to control water evaporation in the plastic state of concrete. The mass percent of each component of the prepared single-phase solution is about: 4.17% of the composite concrete moisture evaporation inhibitor described in this embodiment, 44.92% of ethanol, and 50.91% of water.

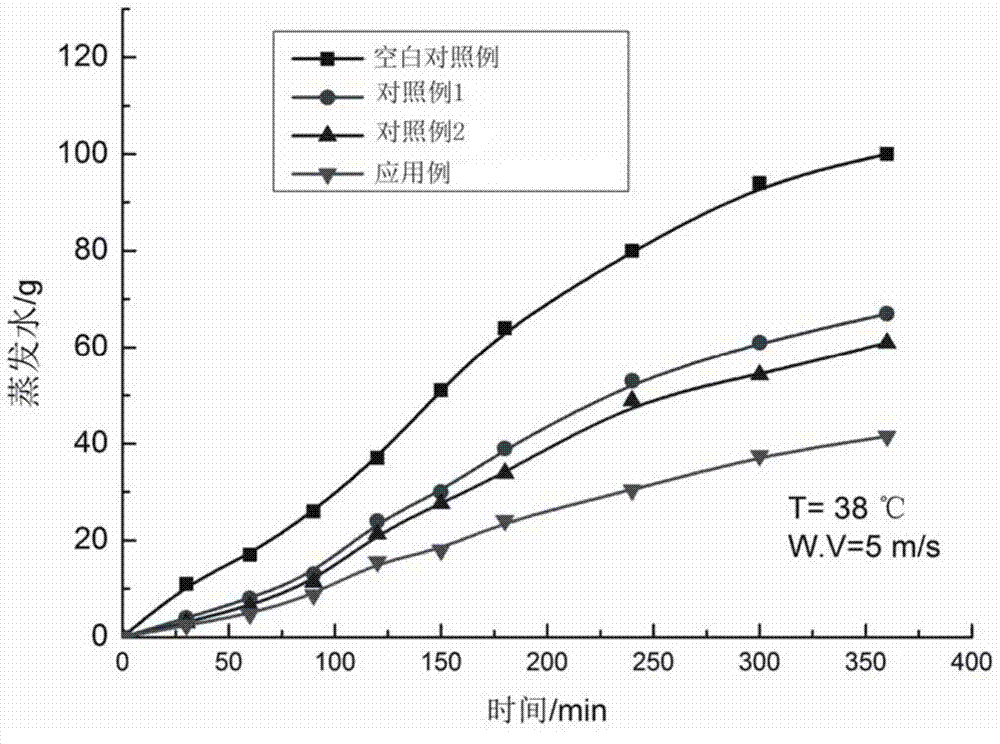

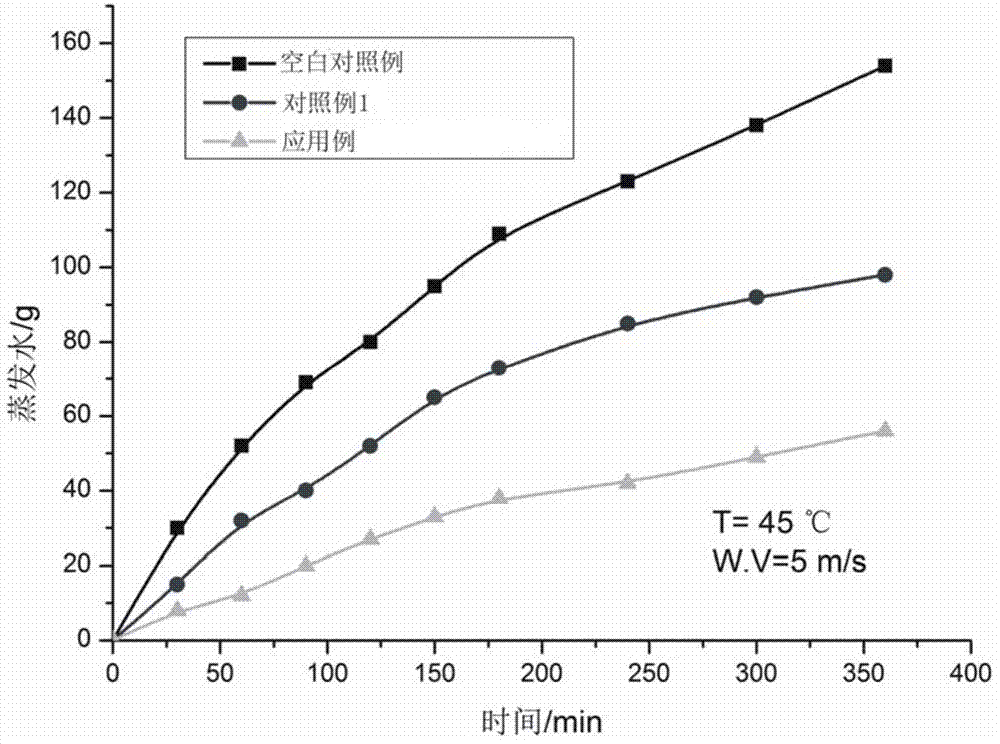

[0035] Application example: the above single-phase solution, weigh 6.96g of the composite concrete water evaporation inhibitor (including 3.92g octadecyltrimethylammonium bromide, 3.04g sodium stearate), 75g ethanol, and 85g water , stirred and mixed at 50° C. for 30 minutes to obtain the single-phase solution described in this example. The single-phase solution was diluted 15 times and sprayed on the surfac...

Embodiment 3

[0039] A composite concrete water evaporation inhibitor, which is composed of cetylpyridinium bromide and sodium octadecylsulfonate, the molar ratio of the two is 1:2.

[0040] The above composite concrete water evaporation inhibitor is prepared into a single-phase solution, which is applied to control water evaporation in the plastic state of concrete. The mass percent of each component of the prepared single-phase solution is about: 3.02% of the composite concrete moisture evaporation inhibitor described in this embodiment, 40.03% of isopropanol, and 56.95% of water.

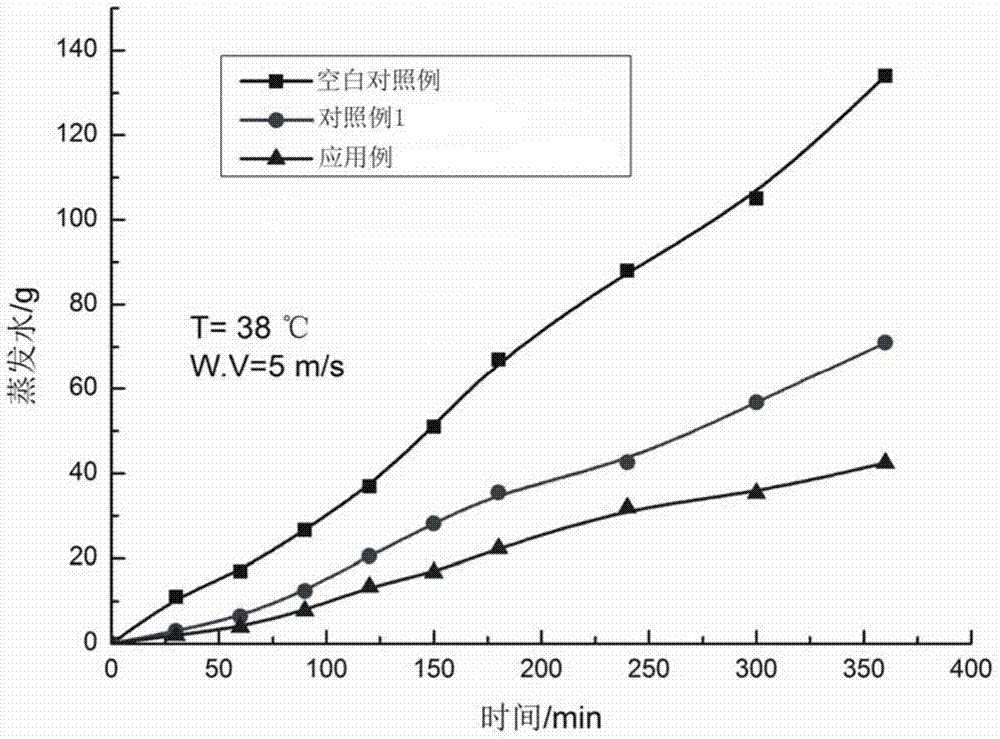

[0041] Application example: the above single-phase solution, weigh 5.35g of the composite concrete moisture evaporation inhibitor (including 1.79g cetylpyridinium bromide, 3.56g sodium octadecylsulfonate), isopropanol 71g, 101 g of water was stirred and mixed at 50° C. for 30 minutes to obtain the single-phase solution described in this example. The single-phase solution was diluted 10 times and sprayed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com