Water-based acrylic red lead rust-proof paint and preparation method thereof

A technology of acrylic red and water-based acrylic acid, applied in the field of coatings, can solve the problems of poor aging resistance, and achieve the effect of fast drying speed and strong anti-corrosion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

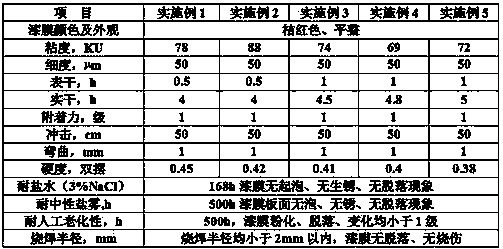

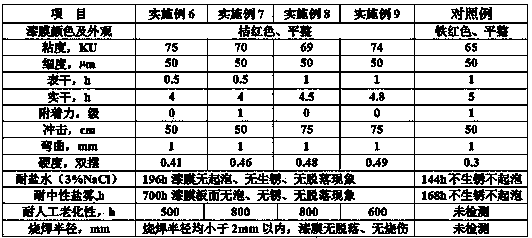

Examples

Embodiment Construction

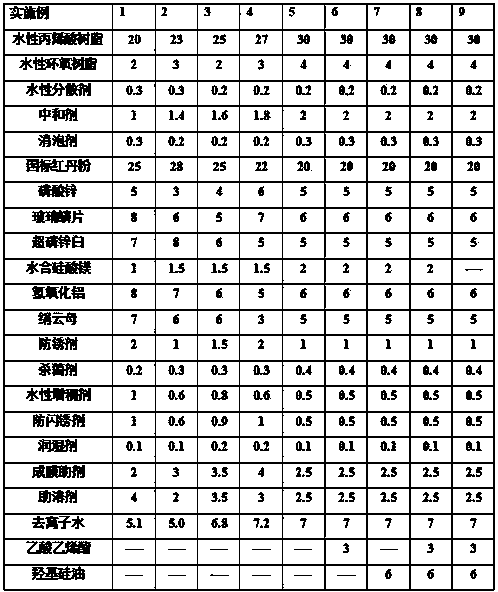

[0028] The raw materials adopted in the following examples are respectively:

[0029] Water-based acrylic resin (KF-0808 Tianjin Kehua)

[0030] Waterborne epoxy resin (3520 Momentive, USA)

[0031] National standard red lead powder (national standard 97 Henan Jiacai)

[0032] Super phosphor zinc white (HJ Zhengzhou Huijin)

[0033] Zinc Phosphate (PZ20 Huanqi Chemical)

[0034] Glass flakes (Langfang Pengxiang Flake Factory)

[0035] Aluminum hydroxide (Hefei Wanran new material)

[0036] Sericite (A4 Chuzhou Wanqiao)

[0037] Dispersant (FX-600 Hymings)

[0038] Wetting agent (C-2817 Haiyi Chemical)

[0039] Coalescing agent (ethylene glycol monobutyl ether American Dow)

[0040] Co-solvent (n-butanol Sinopec)

[0041] Neutralizer (triethylamine chemical shop)

[0042] Anti-flash rust agent (FA-179 Hymings Chemical)

[0043] Defoamer (NXZ Corning Chemicals)

[0044] Hydrated Magnesium Silicate (AD Haiyi Chemical)

[0045] Fungicides (LFMN Haichuan Chemical)

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com