Graphene-silver antibacterial and antifouling fluorocarbon coating, and preparation method and application thereof

A fluorocarbon coating and graphene technology, applied in the coating field, can solve the problems of growth defects and deformities of oysters, low output of natural antifouling agents, large environmental pollution, etc., to achieve improved gloss, stable antibacterial and antifouling performance, low surface energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) 10 parts of graphene oxide and 10 parts of polyethyleneimine were mixed, added to 50 parts of deionized water, then put into a three-necked bottle, and ultrasonically dispersed for 20 minutes to make graphene and polyethyleneimine evenly dispersed; then Stirring and reacting for 3 hours under the conditions of nitrogen flow and 300°C, after the reaction is completed, filter and dry to obtain aminated graphene powder;

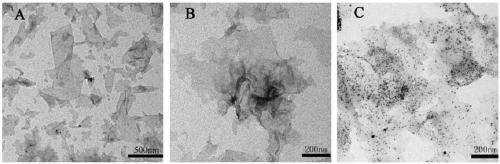

[0064] (2) Mix 10 parts of the aminated graphene powder prepared in step (1) with 10 parts of silver nitrate, add to 50 parts of deionized water, then stir and react at 20°C for 10h, after the reaction is completed, filter and dry, Obtain graphene-silver composite nanomaterial; Wherein, figure 1 It is a transmission electron microscope image of graphene oxide, aminated graphene and graphene-silver composite nanomaterials. As can be seen from the figure, the graphene composite material obtained in this implementation is a single-layer sheet structure. ...

Embodiment 2

[0070] (1) 12 parts of graphene oxide and 12 parts of polyethyleneimine were mixed, added to 55 parts of deionized water, then put into a three-necked bottle, and ultrasonically dispersed for 25 minutes to make graphene and polyethyleneimine evenly dispersed; then Stir and disperse for 3.2 hours under the condition of nitrogen flow and 320°C. After the reaction is completed, filter and dry to obtain aminated graphene powder;

[0071] (2) Mix 12 parts of the aminated graphene powder prepared in step (1) with 12 parts of silver nitrate, add to 55 parts of deionized water, then stir and react at 25°C for 9h, after the reaction is completed, filter and dry, Obtain graphene-silver composite nanomaterial;

[0072] (3) Add 1 part of BYK-180 and 0.5 parts of EFKA-4010 wetting and dispersing agent, 1.5 parts of BYK-320 leveling agent, 1.5 parts of 6800 defoamer and 6 parts of organic bentonite thixotropic agent were then put into a high-speed disperser at 1300r / min for high-speed disp...

Embodiment 3

[0081] (1) 15 parts of graphene oxide and 15 parts of polyethyleneimine were mixed, added to 60 parts of deionized water, then put into a three-necked bottle, and ultrasonically dispersed for 30 minutes to make graphene and polyethyleneimine evenly dispersed; then Stirring and reacting for 3.5 hours under the condition of flowing nitrogen and 350°C, after the reaction is completed, filter and dry to obtain aminated graphene powder;

[0082] (2) Mix 15 parts of the aminated graphene powder prepared in step (1) with 15 parts of silver nitrate, add to 60 parts of deionized water, then stir and react at 30°C for 8h, after the reaction is completed, filter and dry, Obtain graphene-silver composite nanomaterial;

[0083] (3) Add 1 part of BYK-AT203 and 1 part of EFKA-5065 wetting and dispersing agent, 2 parts of TEGO-415 leveling agent, 2 parts BYK-054 defoamer, 2 parts of polyamide wax, 2 parts of organic bentonite and 4 parts of polyurea thixotropic agent, and then placed in a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shock | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com