Industrial continuous production method of fluid rapeseed oil phosphatide with low acid value

A technology of vegetable oil phospholipid and low acid value, which is applied in the direction of producing fat, recovering fatty substances, and recovering fat oil/fatty acid from waste, etc. It can solve the problems of vegetable oil phospholipid resource waste, pollute the environment, and high acid value, and achieve a simple and feasible processing method , No environmental pollution, rich calcium content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

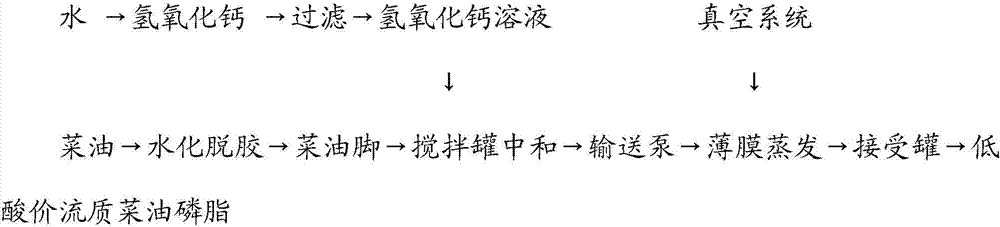

Method used

Image

Examples

Embodiment 1

[0026] 1000kg of rapeseed oil legs with an acid value of 45mg / g are pumped into the preparation tank by a delivery pump, heated to make the temperature of the rapeseed oil legs in the preparation tank reach 65°C, and slowly added through a 40-mesh sieve under stirring conditions of 45rpm / min. Concentration is 200 kilograms of calcium hydroxide solution of 15%, and the acid value of neutralizing vegetable oil foot is 18.5mg / g, and viscosity is 20000 centipoises.

[0027] Then the screw pump is pumped into a thin-film evaporator with a temperature of 115°C and a vacuum of 0.095 MPa for evaporating and dehydrating for 2 to 3 minutes, so that the water content of rapeseed oil phospholipids reaches below 1%, and then pumped into a phospholipid cooler by a screw pump to cool, and then stored in phospholipids. Cans are weighed and packed.

Embodiment 2

[0029] 2000kg of vegetable oil feet with an acid value of 54mg / g is pumped into the preparation tank by a transfer pump, heated to make the temperature of the vegetable oil feet in the preparation tank reach 75°C, and slowly added through an 80-mesh sieve under the stirring condition of 60rpm / min. Concentration is 200 kilograms of calcium hydroxide solution of 15%, and the acid value of neutralizing vegetable oil foot is about 20.5mg / g, and viscosity is 15000 centipoise.

[0030] Then the screw pump is pumped into a thin-film evaporator with a temperature of 125°C and a vacuum of 0.095 MPa for evaporating and dehydrating for 2 to 3 minutes, so that the water content of rapeseed oil phospholipids reaches below 1%, and then pumped into a phospholipid cooler by a screw pump to cool, and then put into phospholipid storage Cans are weighed and packed.

Embodiment 3

[0032] 5000kg of rapeseed oil legs with an acid value of 43mg / g are pumped into the preparation tank by a delivery pump, heated to make the temperature of the rapeseed oil legs in the preparation tank reach 55°C, and slowly added through a 60-mesh sieve under stirring conditions of 30rpm / min. Concentration is 300 kilograms of calcium chloride solution of 15%, and the acid value of neutralizing vegetable oil foot is about 17.5mg / g, and viscosity is 13000 centipoise.

[0033] Then the screw pump is pumped into a thin film evaporator with a temperature of 130°C and a vacuum of 0.095 MPa for evaporating and dehydrating for 2 to 3 minutes, so that the water content of rapeseed oil phospholipids reaches below 1%. Cans are weighed and packed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com