Sealing method for ceramic vitrification

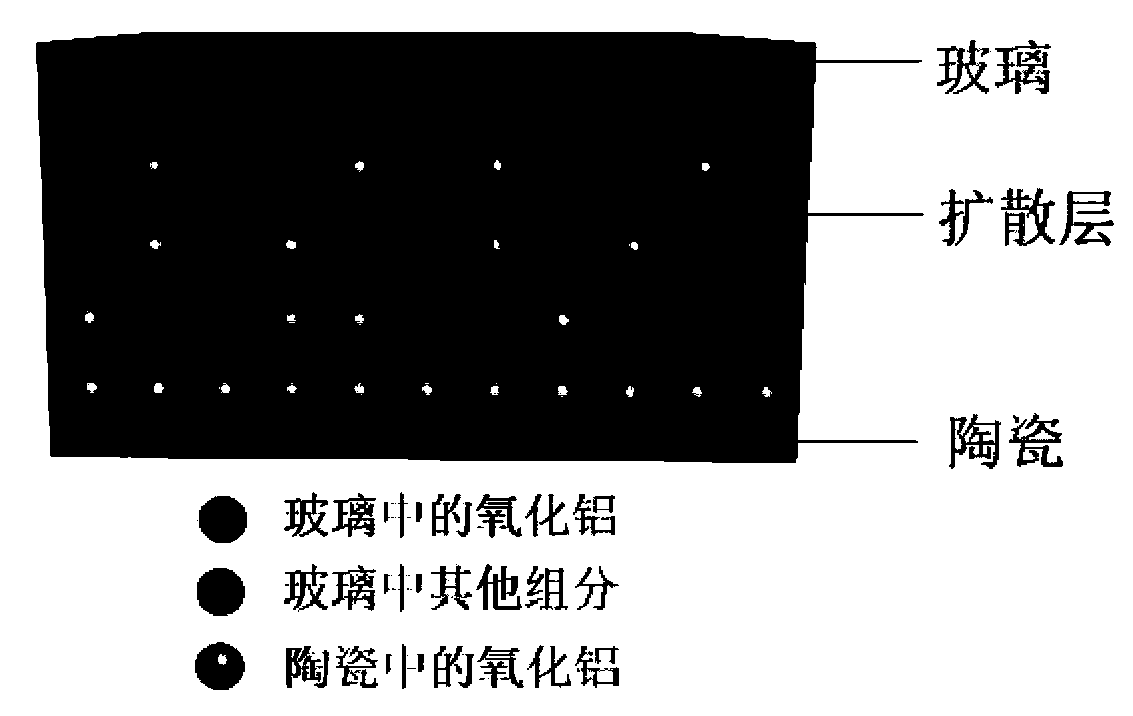

A technology of ceramic glass and glass, which is applied in the sealing field of ceramic vitrification, can solve the problems of increased cost and difficulty, certain requirements for control, and difficulty in guaranteeing the airtightness, stability and reliability of the sealing interface, etc. Achieve good air tightness, reduce energy consumption, and high interface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] (1) Preparation of glass powder with matching thermal expansion coefficient

[0028] Based on conventional borosilicate glass, the basic component is SiO 2 , B 2 o 3 or H 3 BO 3 、Al 2 o 3 , R 2 O or R 2 CO 3 (R 2 O is for Li 2 O, Na 2 O, K 2 One or more of O, R 2 CO 3 for Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 One or more of them), and according to the composition and thermal expansion coefficient of the ceramic matrix, add MgO, Bi 2 o 3 , ZrO 2 、TiO 2 Control the composition and thermal expansion coefficient of the glass to match the ceramic matrix; melt all the raw materials at a high temperature of 1200-1600°C for 30-360 minutes; obtain glass slag after rapid cooling; the glass slag is ball milled and sieved Finally, glass powder is obtained, preferably the particle size of the glass powder is 2-200 μm.

[0029](2) Mix the glass powder in step (1) with a binder and a solvent to make a paste. The binder includes but not limited to polyvinyl butyral (...

Embodiment 1

[0042] (a) Preparation of glass frits with matched thermal expansion coefficients

[0043] beta-Al 2 o 3 The coefficient of thermal expansion is 6~7×10 -6 K -1 (25~300℃), select the thermal expansion coefficient to match it and the composition contains Al 2 o 3 borosilicate glass as sealing glass. SiO 2 、Al 2 o 3 、H 3 BO 3 、Na 2 CO 3 、K 2 CO 3 , Li 2 CO 3 、 Bi 2 o 3 According to composition SiO 2 :Al 2 o 3 :B 2 o 3 : Na 2 O:K 2 O: Li 2 O: Bi 2 o 3 =40:3:18:3:3:1:32 for batching; use absolute ethanol as the medium, ball mill for 4 hours, dry; sinter at 800°C for 2 hours, and then melt at 1400°C for 2 hours; After cooling, glass slag is obtained; the glass slag is ball milled and sieved to obtain glass powder, preferably with a particle size of 10-20 μm. The coefficient of thermal expansion of the glass powder at 25-300°C is 6.2×10 -6 K -1 .

[0044] (b) Preparation of glass paste

[0045] Using absolute ethanol as solvent and PVB with a weight r...

Embodiment 2

[0053] (a) Preparation of glass powder with matching coefficient of thermal expansion: same as Example 1;

[0054] (b) Preparation of glass paste: use a mixture of ethanol and terpineol (1:4) as a solvent, and EC with a weight ratio of 3% as a binder, and prepare the glass powder obtained in (a) so that the composition is uniform ointment;

[0055] (c) same as embodiment 1;

[0056] (d) Vitrification of the surface of the sealing part of the ceramic sealing element: same as in Example 1;

[0057] (e) Sealing of ceramics and metals: same as Example 1;

[0058] The detection results of the helium mass spectrometer leak detector show that the helium leakage rate of the seal is 10 -11 Pa·m 3 ·s -1 ; Mechanical performance test results show that the seal strength of the seal is about 91MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com