A kind of dephosphorization agent and its application

A dephosphorization agent and a form of technology, applied in the field of dephosphorization agent, can solve the problems of containing fluorite and affecting the hardenability of steel, so as to achieve the effect of increasing activity, reducing the amount of slag, and good dephosphorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Dephosphorization agent component (percentage is mass percent):

[0055] Fe 2 o 3 :33, CaO:38, SiO 2 :20, Na 2 O:3, Al 2 o 3 :6

[0056] The dephosphorization experiment was carried out in a high-temperature resistance furnace, the weight of the carbon-saturated molten iron sample was 300g, the molten iron composition [P]=0.518%, [Si]≤0.10wt%0.1wt%; the dephosphorization temperature was controlled at 1350°C, at this temperature Next, add 30g of the prepared dephosphorization agent into the molten iron in the form of upper part input, and stir with a molybdenum rod. After 30 minutes of dephosphorization, the molten iron [P] drops to 0.076%, and the dephosphorization rate is 85.34%.

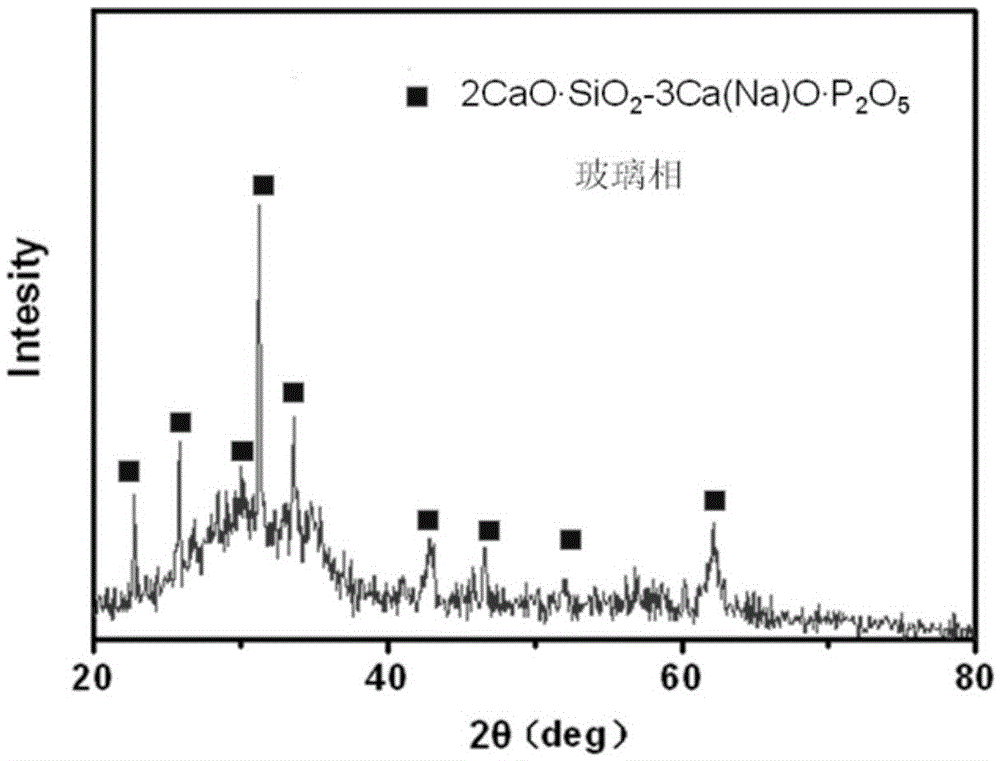

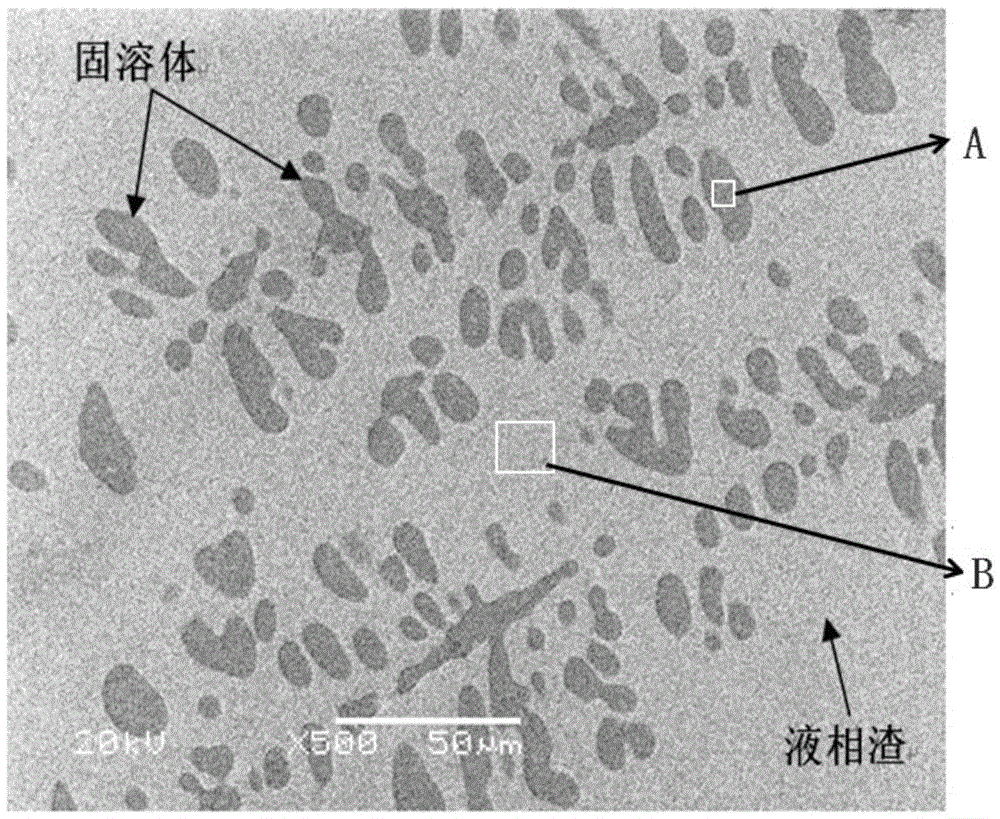

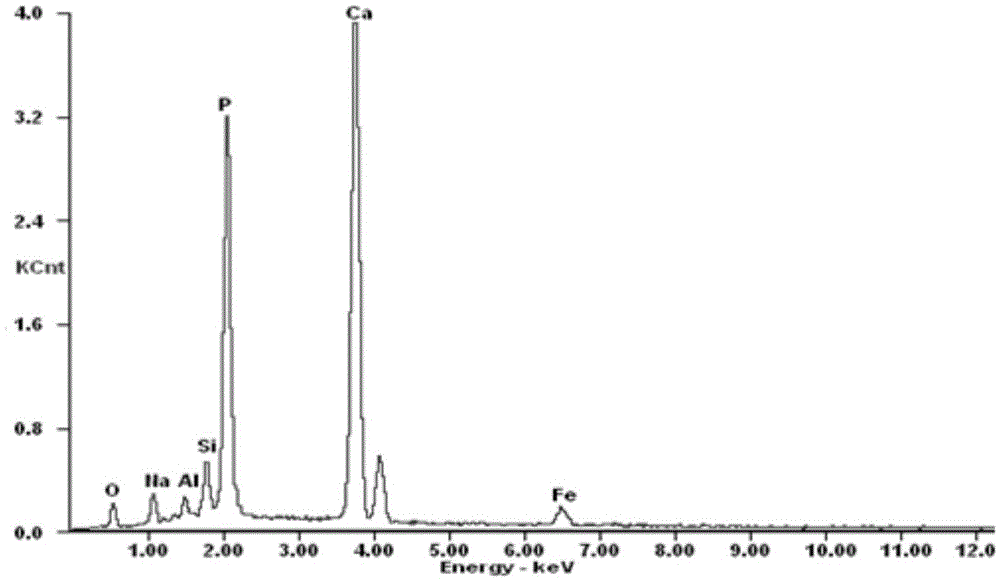

[0057] The dephosphorization final slag of Example 1 was subjected to water quenching treatment, and after drying and grinding, XRD powder diffraction analysis was carried out. The analysis results showed that there were only two phases in the dephosphorization final slag, one of whic...

Embodiment 2

[0061] Dephosphorization agent component (percentage is mass percent):

[0062] Fe 2 o 3 :25, CaO:45, SiO 2 :17, Na 2 O:10, Al 2 o 3 :3

[0063] The dephosphorization experiment was carried out in a high-temperature resistance furnace. The weight of the carbon-saturated molten iron sample was 300g, and the molten iron composition [P]=0.765%, [Si]≤0.10wt%. Add 30 g of the dephosphorization agent prepared above into molten iron and stir with a molybdenum rod. After 30 minutes of dephosphorization, the molten iron [P] drops to 0.113%, and the dephosphorization rate is 85.25%.

Embodiment 3

[0065] Dephosphorization agent component (percentage is mass percent):

[0066] Fe 2 o 3 :28, CaO:32, SiO 2 :30, Na 2 O:3, Al 2 o 3 :7

[0067] The dephosphorization experiment was carried out in a high-temperature resistance furnace. The weight of the carbon-saturated molten iron sample was 300g, the molten iron composition [P]=0.518%, and [Si]≤0.10wt%. Add 30 g of the dephosphorization agent prepared above into molten iron and stir with a molybdenum rod. After 30 minutes of dephosphorization, the molten iron [P] drops to 0.084%, and the dephosphorization rate is 83.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com