Environment-friendly type phosphate concentrated liquor for removing rust and iron oxide scales and phosphating and application of environment-friendly type phosphate concentrated liquor

A technology for concentrating iron oxide scale and phosphoric acid, which is applied in the coating process of metal materials, etc., can solve problems such as long cleaning time of rust and oxide scale, insignificant coating performance and anti-rust effect, low content of phosphoric acid and effective substances, etc. Achieve the effect of convenient production, simple ingredients, and thorough rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

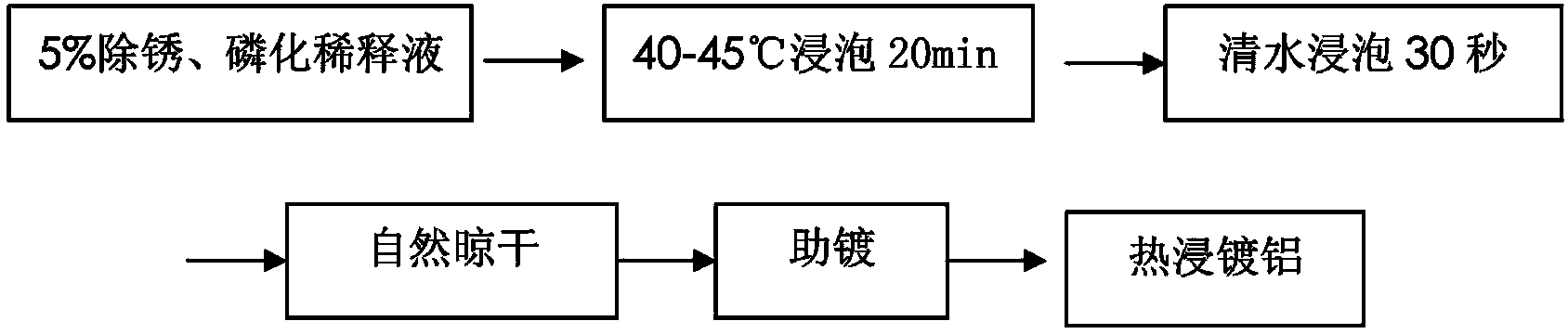

[0037] Weigh 90 kg of phosphoric acid, add 3 kg of citric acid monohydrate and stir to dissolve, then add 2 kg of calcium phosphate and 4.9 kg of zinc phosphate, stir and dissolve until transparent, and finally add 0.1 kg of fluorine-containing alkyl quaternary ammonium salt cation Surfactant compounded with ethylene oxide adduct of fluorine-containing polypropylene glycol to prepare concentrate.

[0038] Dilute the concentrated solution 10 times with tap water to a concentration of 10%, soak a Φ13.5mm×60mm wire rod at 40°C for 20 minutes, and dry it in the air. Measure the surface appearance, thickness, adhesion and salt spray resistance of the phosphating film formed on the surface. The phosphating film on the surface is black, and there is no ash phenomenon; the measured thickness of the phosphating film can reach 24-25um; the adhesion is grade 1; the neutral salt spray resistance time is not less than 3 hours. See Table 2 for comparison indicators and reference standards ...

Embodiment 2

[0040] Zinc phosphate is 2.4kg, and other composition and content and preparation and use method thereof are with embodiment 1.

[0041] The phosphating film on the surface is black, and there is no ash phenomenon; the measured thickness of the phosphating film can reach 20-23um; the adhesion is grade 1; the neutral salt spray resistance time is not less than 3 hours.

Embodiment 3

[0043] Zinc phosphate is 0.8kg, and other composition and content and preparation and use method thereof are with embodiment 1.

[0044] The phosphating film on the surface is black, and there is no ash phenomenon; the measured thickness of the phosphating film can reach 15-17um; the adhesion is grade 2; the neutral salt spray resistance time is not less than 2.8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com