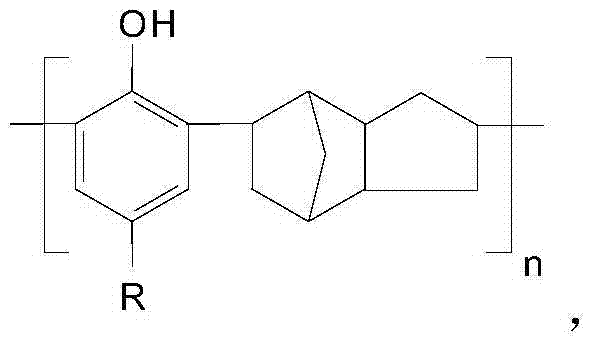

Macromolecular polymerized phenol modified polydicyclopentadiene material and preparation method thereof

A technology for polydicyclopentadiene and dicyclopentadiene is applied in the field of preparation of macromolecular polymerized phenol modified polydicyclopentadiene materials, which can solve problems such as inability to meet the requirements of use, and achieve high production efficiency and convenient operation. , the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The macromolecule polymerized phenol modified polydicyclopentadiene material in this embodiment is made of dicyclopentadiene monomer, tungsten phenol complex, monochlorodiethylaluminum and macromolecular polymerized phenol, and is molded by reaction injection process; wherein, the structural formula of the tungsten phenol complex is W(OPhR) 3 Cl 3 , wherein OPhR is a nonylphenoxy group; the molar ratio of the dicyclopentadiene monomer, tungsten phenol complex, and diethylaluminum chloride is 1000:1:15, and the addition amount of the macromolecular polymerized phenol It is 1% of the mass of dicyclopentadiene monomer.

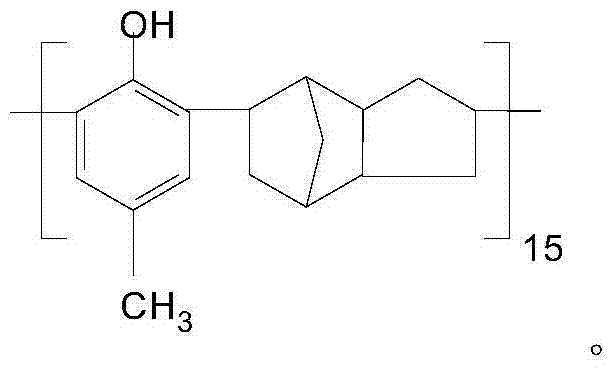

[0025] The macromolecular polymerized phenol is a linear condensation polymer of dicyclopentadiene monomer and p-methylphenol, and its structural formula is:

[0026]

[0027] Described macromolecule polyphenol is prepared by following method:

[0028] In a three-neck flask with stirring, reflux condenser, and thermometer, add toluene (solvent), p-cr...

Embodiment 2

[0032] The macromolecule polymerized phenol-modified polydicyclopentadiene material in this embodiment uses dicyclopentadiene monomer, molybdenum phenol complex, monochlorodiethylaluminum and macromolecular polymerized phenol as raw materials, and is molded by reaction injection Process is made; Wherein, the structural formula of described molybdenum phenol complex is Mo(OPhR) 3 Cl 2 , wherein OPhR is a nonylphenoxy group; the molar ratio of the dicyclopentadiene monomer, molybdenum phenol complex, and diethylaluminum chloride is 1500:1:20, and the addition amount of the macromolecular polymeric phenol It is 4% of the mass of dicyclopentadiene monomer.

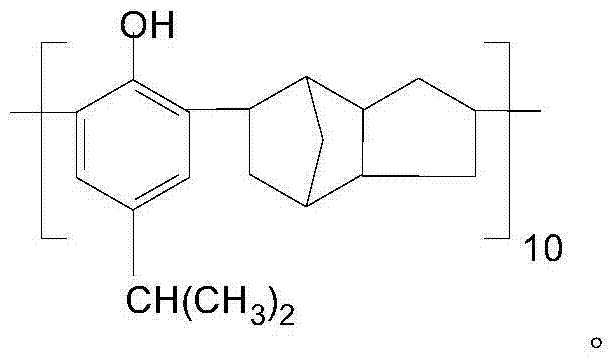

[0033] The macromolecular polymerized phenol is a linear condensation polymer of dicyclopentadiene monomer and p-isopropylphenol, and its structural formula is:

[0034]

[0035] Described macromolecule polyphenol is prepared by following method:

[0036] In a three-neck flask with stirring, reflux condenser, and thermom...

Embodiment 3

[0040] The macromolecular polymerized phenol modified polydicyclopentadiene material in this embodiment is made of dicyclopentadiene monomer, tungsten phenol complex, triethylaluminum and macromolecular polymerized phenol through reaction injection molding process. into; wherein, the structural formula of the tungsten phenol complex is W(OPhR) 3 Cl 3 , wherein OPhR is nonylphenoxy; the molar ratio of the dicyclopentadiene monomer, tungsten phenol complex, and triethylaluminum is 1800:1:25, and the addition amount of the macromolecule polymerized phenol is bicyclic 8% of the mass of pentadiene monomer.

[0041] The macromolecular polymerized phenol is a linear condensation polymer of dicyclopentadiene monomer and hexylphenol, and its structural formula is:

[0042]

[0043] Described macromolecule polyphenol is prepared by following method:

[0044] In a three-neck flask with stirring, reflux condenser, and thermometer, add ethylbenzene (solvent), hexylphenol and BF 3 ·E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com