Preparation process of montelukast sodium and its intermediate product

A technology of montelukast sodium and preparation process, applied in the field of drug synthesis, can solve the problems of high price of montelukast sodium, increased production cost, increased medical cost of patients, etc., and achieves simple operation, high total yield, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

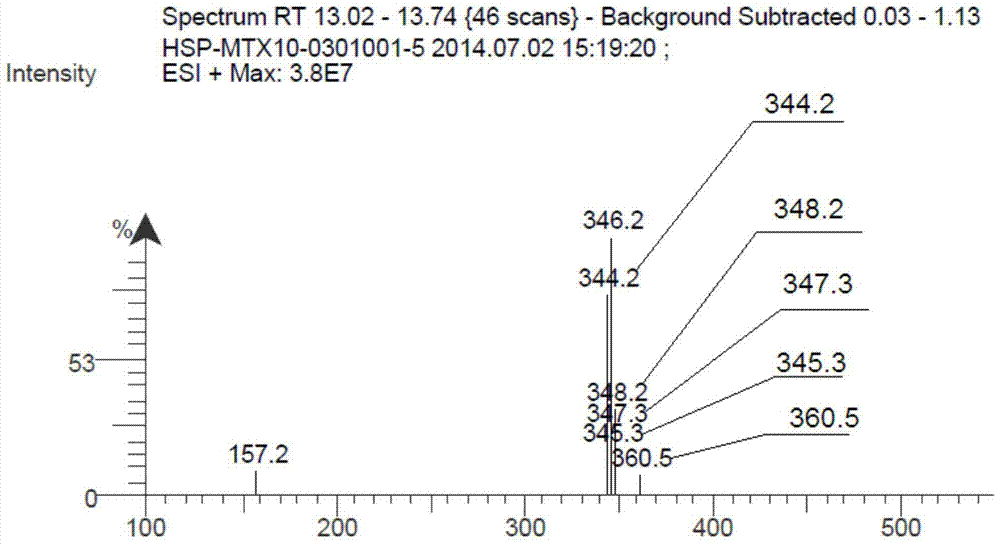

[0050] The preparation of embodiment 1 compound A2

[0051] In a 1000ml three-necked flask, first add 300ml of toluene and 4.8ml of glacial acetic acid (0.084mol, 0.3eq), and under mechanical stirring, add 50g (0.28mol, 1eq) of 7-chloro-2-methylquinine, 3-bromobenzene Formaldehyde 77.7g (0.42mol, 1.5eq), after the feeding is complete, heat up to 70°C, add 45ml (0.48mol, 1.71eq) of acetic anhydride after the raw materials are completely dissolved, then heat up to toluene reflux, control the temperature at 120-125°C, reflux After 10 hours, TLC detected the reaction until the raw material point of 7-chloro-2-methylquinine disappeared, the reaction was completed, the heating was stopped, the reaction solution was cooled to room temperature, stirred for 2 hours, left to stand for 1 hour, suction filtered, and the filter cake was used for 30ml Wash with toluene and dry. 86.8g of the product compound A2 was obtained, the yield was 90%, MS m / z: 346 (M+1) + .

Embodiment 2

[0052] The preparation of embodiment 2 compound A2

[0053] In a 1000ml three-necked flask, first add 300ml of toluene and 8ml of glacial acetic acid (0.14mol, 0.5eq), under mechanical stirring, add 50g (0.28mol, 1eq) of 7-chloro-2-methylquinine, 3-bromobenzaldehyde 62.16g (0.34mol, 1.2eq), after the addition is complete, heat up to 70°C, add 45ml (0.48mol, 1.71eq) of acetic anhydride after all the raw materials are dissolved, then heat up to toluene reflux, control the temperature at 120-125°C, and reflux for 11 After 1 hour, TLC detects the reaction until the 7-chloro-2-methylquinine raw material point disappears, the reaction ends, the heating is stopped, the reaction solution is cooled to room temperature, and after stirring for 2 hours, it is left to stand for 1 hour, suction filtered, and the filter cake is washed with 30ml toluene Wash and dry. 82.9g of the product compound A2 was obtained, the yield was 86%, MS m / z: 346 (M+1) + .

Embodiment 3

[0054] The preparation of embodiment 3 compound A2

[0055] In a 1000ml three-neck flask, first add 350ml xylene and 4.8ml (0.084mol, 0.3eq) of glacial acetic acid, and under mechanical stirring, add 50g (0.28mol, 1eq) of 7-chloro-2-methylquinine, 3-bromo Benzaldehyde 62.16g (0.34mol, 1.2eq), after the feeding is complete, heat up to 70°C, add propionic anhydride 54.6ml (0.42mol, 1.5eq) after the raw materials are completely dissolved, then heat up to toluene reflux, control the temperature at 120-125°C , refluxed for 12 hours, TLC detected the reaction until the raw material point of 7-chloro-2-methylquinine disappeared, the reaction was completed, the heating was stopped, the reaction solution was cooled to room temperature, stirred for 2 hours, left to stand for 1 hour, suction filtered, and the filter cake was Wash with 30 ml of toluene and dry. Obtained product A2 84.4g, yield 87.5%, MS m / z: 346(M+1) + .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com