Detection method of content of acrylamide monomer in paper and paper product

A technology of acrylamide monomer and detection method, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of increased uncertainty in the accuracy of measurement results, long processing cycles, expensive instruments, etc., to avoid baseline instability, The effect of improving extraction speed and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 draws standard curve

[0024] Standard solutions of acrylamide with concentrations of 0, 0.05, 0.1, 0.2, 0.3, 0.4, 0.5, and 1.0 μg / mL were prepared by conventional methods, and analyzed by high performance liquid chromatography (HPLC) under the following conditions:

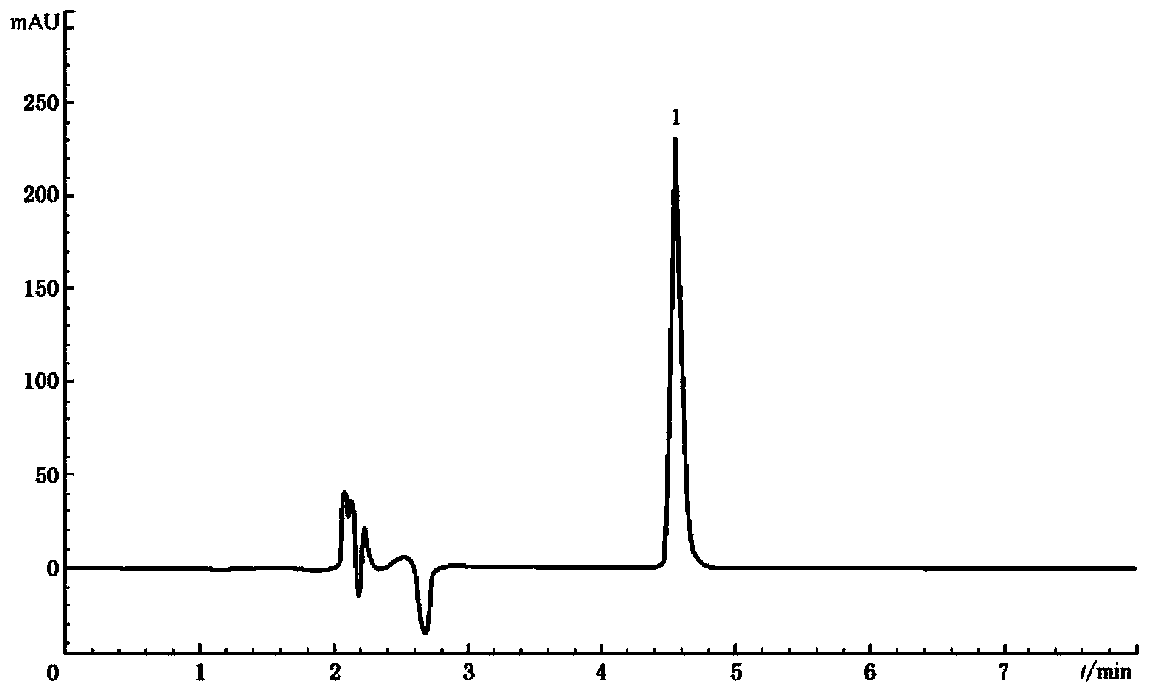

[0025] Chromatographic column (Waters2695): C18, stationary phase particle size 5μm, 250mm×4.6mm (inner diameter) or equivalent; column temperature: 30°C; detection wavelength: 197nm; mobile phase: methanol:water=5:95 (volume ratio) ; Flow rate: 1.0 mL / min; Injection volume: 20 μL.

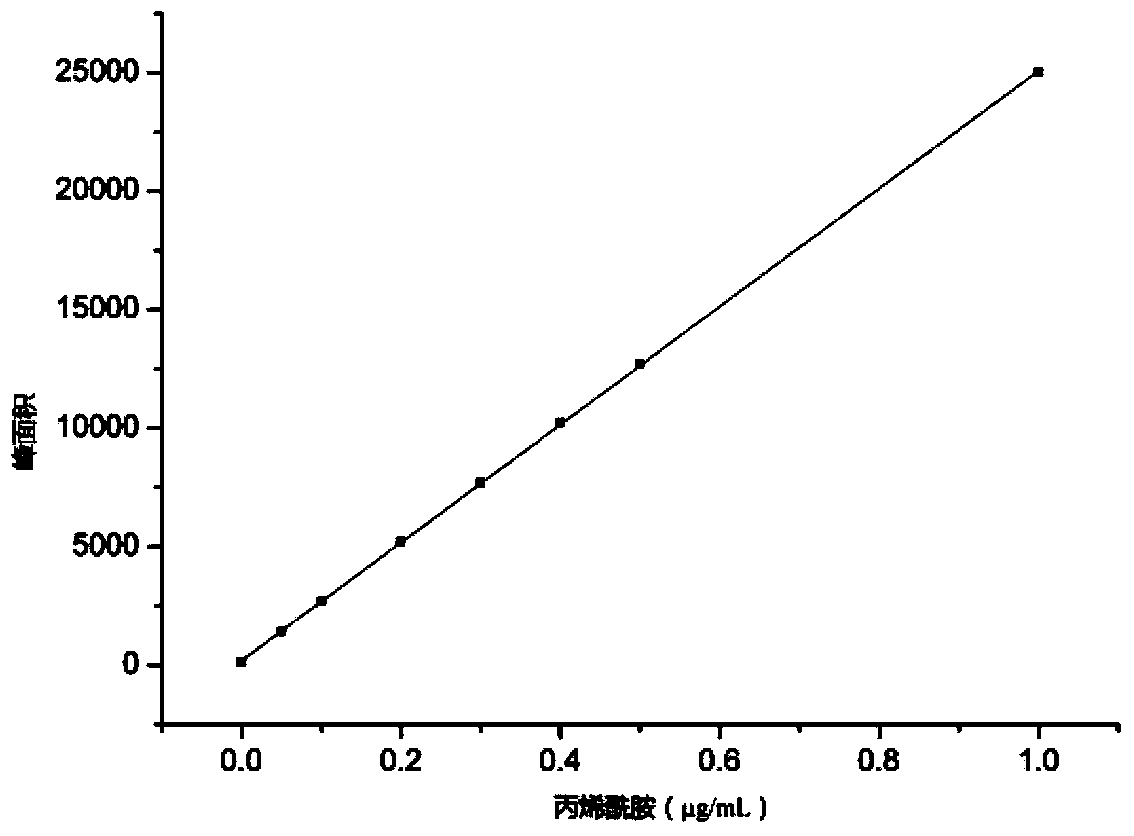

[0026] like figure 1 As shown, according to the HPLC spectrogram, under the given conditions above, the retention time of acrylamide is 4.6min. Take the acrylamide concentration as the abscissa and the chromatographic peak area as the ordinate to draw a standard curve, see figure 2 , get the regression equation y=24879x+197.8, correlation coefficient R2=0.9999. It can be seen that within the concentration ran...

Embodiment 2

[0028] In this embodiment, a certain writing paper purchased in the market is used as the tested sample, and 5g of paper sample is weighed to an accuracy of 0.1mg. The ratio of (ml) to paper sample (g) is 4:1, cover the stopper, shake the Erlenmeyer flask in a constant temperature water bath at 60°C for 2 hours, then take out the Erlenmeyer flask, cool it to room temperature, and place it in a high-speed centrifuge Centrifuge at 1000r / min for 20min, and filter the supernatant liquid through a 0.45μm membrane filter. Take 1.0mL of the filtrate to pass through the HLB solid phase extraction column. Before passing through the HLB solid phase extraction column, use 3.5mL methanol and 3.5mL water to activate the HLB solid phase extraction column in advance. After all the filtrate flows out of the solid phase extraction column, use 3mL5% elute with methanol aqueous solution, collect the eluate, filter through a 0.22 μm filter membrane, and wait for HPLC detection.

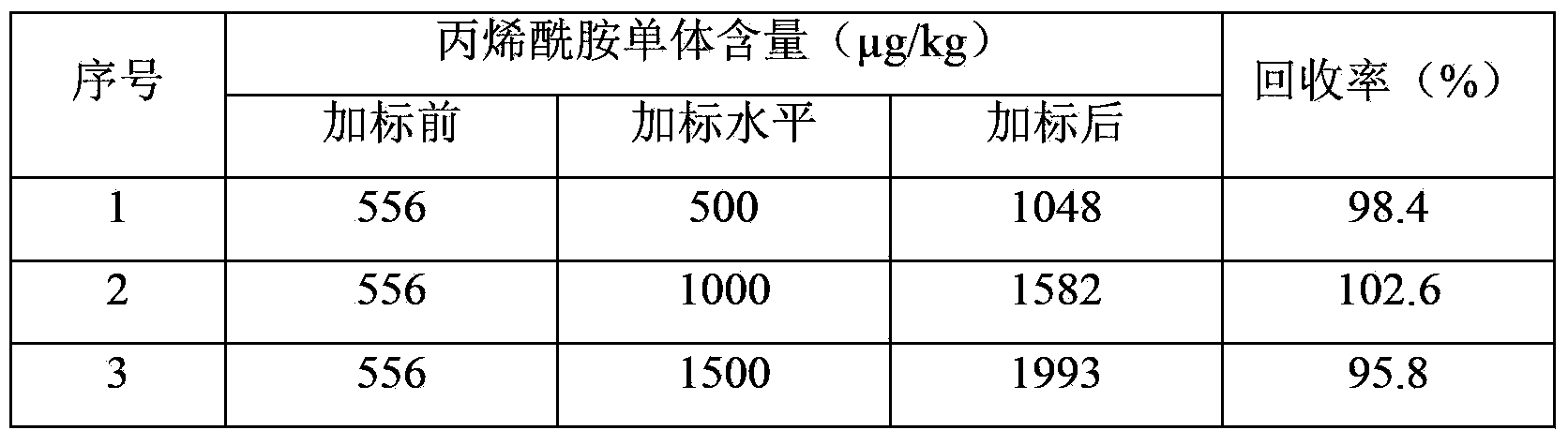

[0029] Adopt th...

Embodiment 3

[0031] In this embodiment, a certain living paper purchased in the market is used as the tested sample, and 5g of paper samples are weighed to an accuracy of 0.1 mg. After the paper samples are pulverized, they are added to a conical flask with a stopper, and then 30ml of aqueous methanol is added to the conical flask. The ratio of methanol aqueous solution (ml) to paper sample (g) is 6:1, the volume fraction of methanol is 5%, cover the stopper, place the Erlenmeyer flask in a constant temperature water bath at 30°C for 4 hours, then take out the Erlenmeyer flask and cool to room temperature, placed in a high-speed centrifuge and centrifuged at 1000r / min for 20min, and the supernatant liquid was filtered through a 0.45μm membrane filter. Take 1.0mL of the filtrate to pass through the HLB solid phase extraction column. Before passing through the HLB solid phase extraction column, use 3.5mL methanol and 3.5mL water to activate the HLB solid phase extraction column in advance. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com