Diesel vehicle tail gas catalyst reduction composition

A technology for catalysts and diesel vehicles, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as secondary pollution, achieve stable atomization, improve high and low temperature adaptability, and have good flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

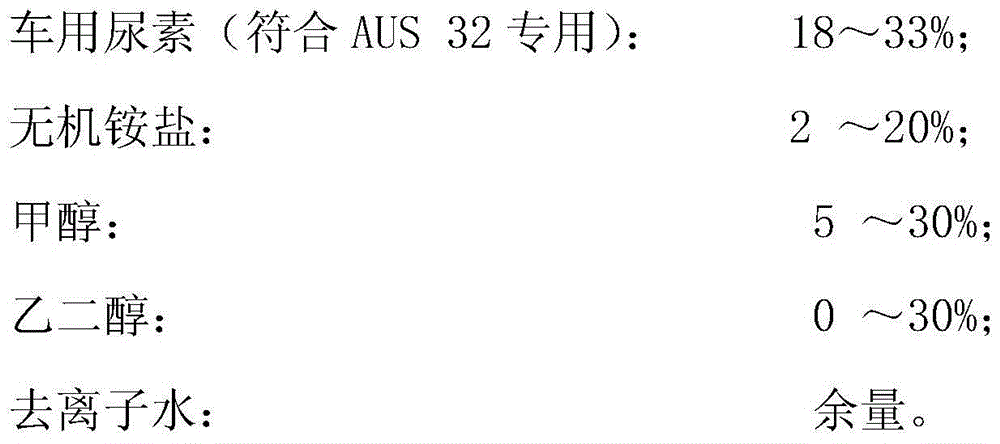

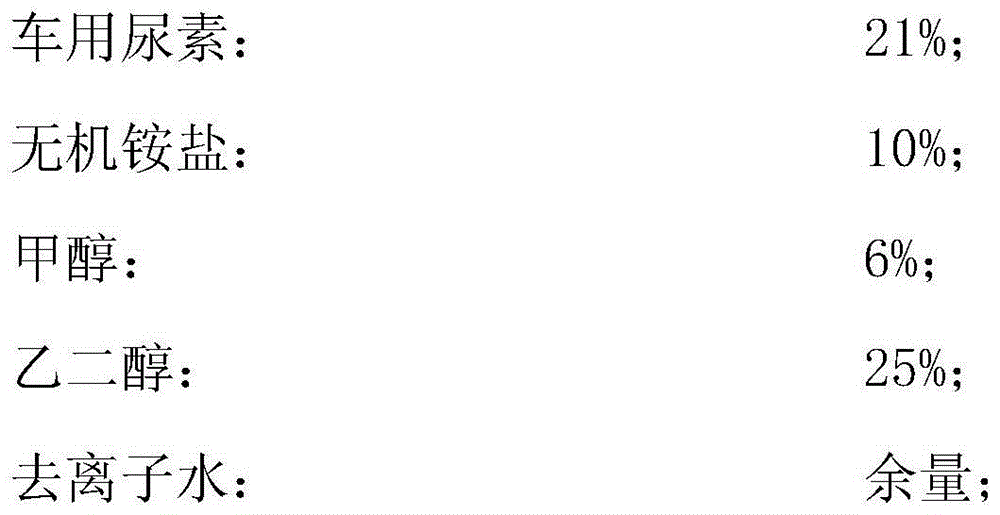

[0027] The composition ratio of the present embodiment is as follows (by mass ratio):

[0028]

[0029] In this embodiment, in order to avoid the decomposition of ammonium bicarbonate in the process of preparing the solution, the steps of preparing the composition of the present invention are as follows: add 380 kg of deionized water in a 2000 kg reactor, add 210 kg of vehicle urea, and add it immediately after stirring for 2 minutes 100kg of ammonium bicarbonate, after stirring to dissolve, slowly add 60kg of methanol and 250kg of ethylene glycol, mix evenly, and filter and fill through a 0.1-0.5um filter after passing the test.

[0030] The product of this example can meet the requirements for use at a low temperature of -40°C, and can be stored in an environment from room temperature to -40°C for more than 2 years without any precipitation and crystallization.

[0031] The finished product has been tested by SGS for trace elements and meets the requirements for the use o...

Embodiment 2

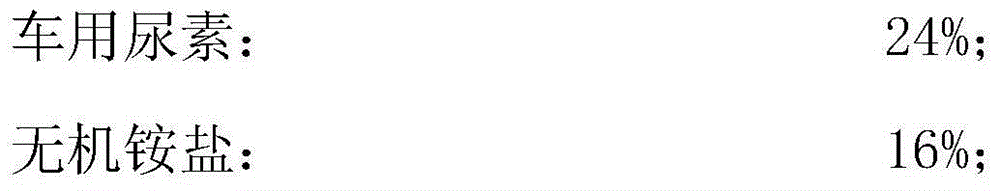

[0035] The composition ratio of the present embodiment is as follows (by mass ratio):

[0036]

[0037] In the present embodiment, in order to avoid the decomposition of ammonium bicarbonate in the process of preparing the solution, the steps of preparing the composition of the present invention are as follows: add 505 kg of deionized water in a 2000 kg reactor, add 240 kg of vehicle urea, and add it immediately after stirring for 2 minutes 160kg of ammonium bicarbonate, after stirring and dissolving, slowly add 90kg of methanol and 5kg of ethylene glycol, mix evenly, filter and fill through a 0.1-0.5um filter after passing the test.

[0038] The product of this embodiment can meet the use requirements of low temperature -20°C, and it can be stored at room temperature to -20°C for more than 2 years without precipitation and any crystallization.

[0039] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com