A kind of graphene oxide-based rare earth composite catalytic material and preparation method thereof

A catalytic material, graphene-based technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as not meeting the requirements of complete conversion, and achieve Improve catalytic reaction efficiency, improve catalytic activity, and improve the effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) The perovskite rare earth oxide material LaCoO 3 10g was dissolved in 80ml deionized water, ultrasonicated for 2 hours, transferred to a reaction kettle, and sealed;

[0044] (2) The hydrothermal reaction temperature is 180°C, and the reaction time is 24h;

[0045] (4) After the hydrothermal reaction finishes, the reactor is cooled to room temperature with the oven;

[0046] (5) Filter the product and wash it several times with deionized water until pH=6;

[0047] (6) Put it in an oven and dry it at 80°C to obtain a hydrothermally treated lanthanum cobaltate sample;

Embodiment 2

[0050] (1) The perovskite rare earth oxide material LaCoO 3 10g and 50g of ethylenediamine were dissolved in 80ml of deionized water, ultrasonicated for 2 hours, transferred to the reaction kettle, and sealed; (this example did not add graphene oxide, as a comparative example, to illustrate the effect of graphene oxide)

[0051] (2) The hydrothermal reaction temperature is 180°C, and the reaction time is 24h;

[0052] (4) After the hydrothermal reaction finishes, the reactor is cooled to room temperature with the oven;

[0053] (5) The product is filtered and washed with deionized water several times until pH=6;

[0054] (6) drying in an oven at 80° C. to obtain a hydrothermally-treated surface-activated rare earth oxide catalyst;

Embodiment 3

[0056] (1) The perovskite rare earth oxide material LaCoO 3 10g, 50g of ethylenediamine, 8ml of graphene oxide suspension (80mg / ml) were dissolved in 80ml of deionized water, ultrasonicated for 2 hours, transferred to the reaction kettle, and sealed;

[0057] (2) The hydrothermal reaction temperature is 180°C, and the reaction time is 24h;

[0058] (4) After the hydrothermal reaction finishes, the reactor is cooled to room temperature with the oven;

[0059] (5) The product is filtered and washed with deionized water several times until pH=6;

[0060] (6) Putting it into an oven for drying at 80° C. to obtain a graphene oxide-based hydrothermally treated surface-activated rare earth oxide composite catalyst;

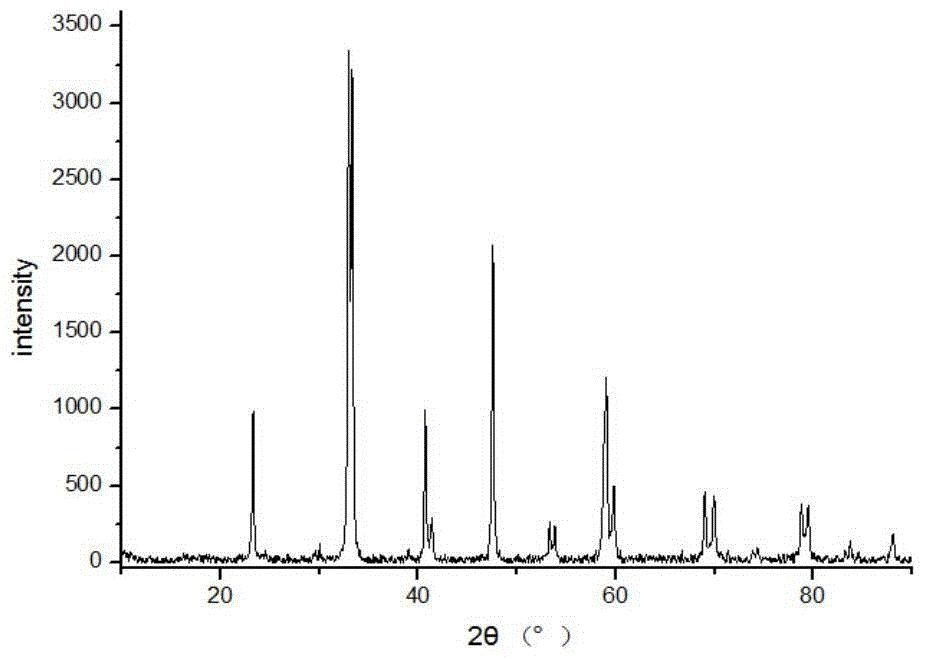

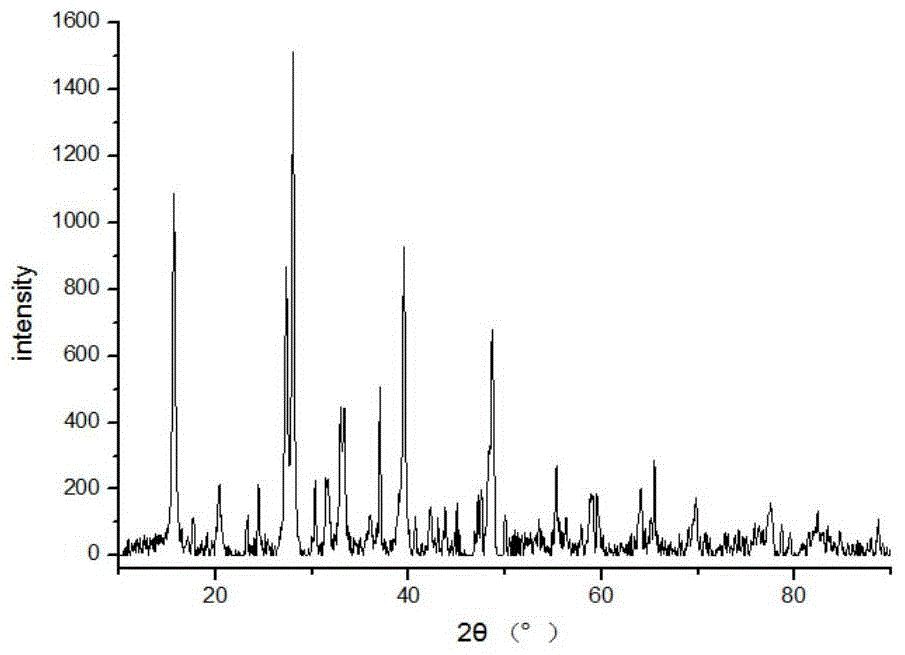

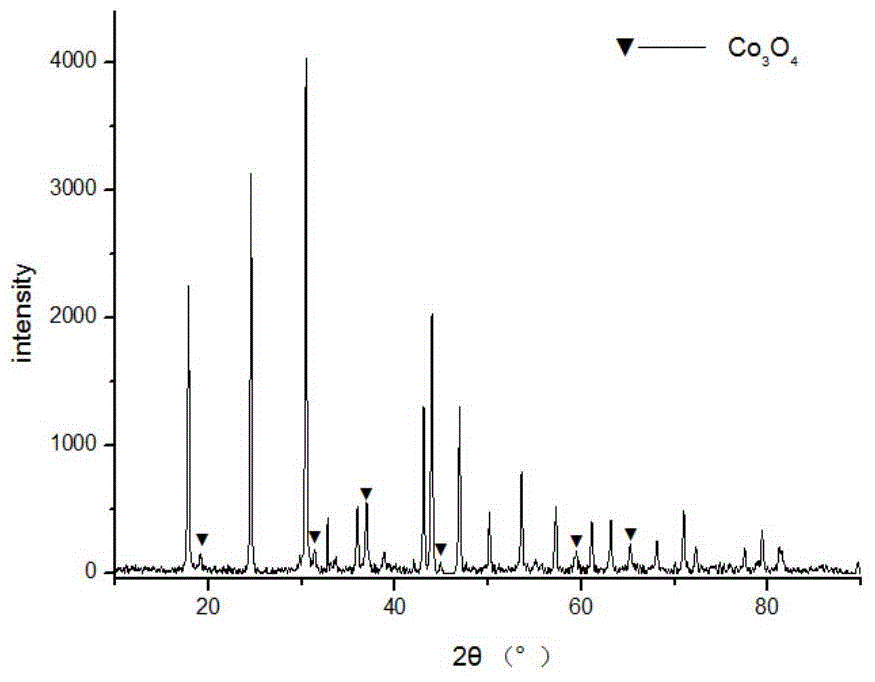

[0061] figure 1 Untreated perovskite-type rare earth oxide material LaCoO 3 From the XRD pattern of the sample, it can be seen that the sample has good crystallinity and no impurity phase is formed. figure 2 It is the XRD pattern of the sample of Example 1. It can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com