High-temperature-resistant corrosion-resistant furnace body for fluidizing chlorination furnace and manufacturing method of high-temperature-resistant corrosion-resistant furnace body

A technology of a boiling chlorination furnace and a production method, which is applied to titanium tetrachloride, titanium halide and other directions, can solve the problems of difficult maintenance, low production operation rate, poor resistance to high temperature chlorine gas corrosion and flue gas scouring, etc. Ensure cleanliness and roughness, enhance shock resistance, and ensure the effect of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

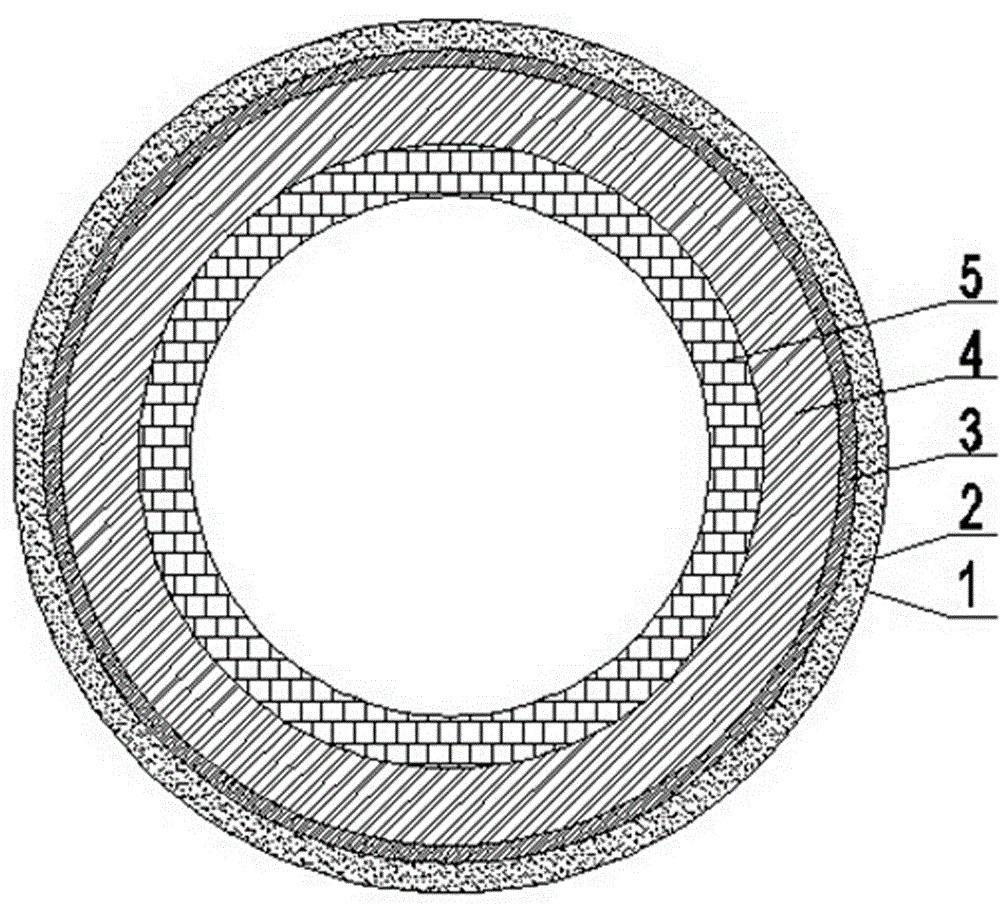

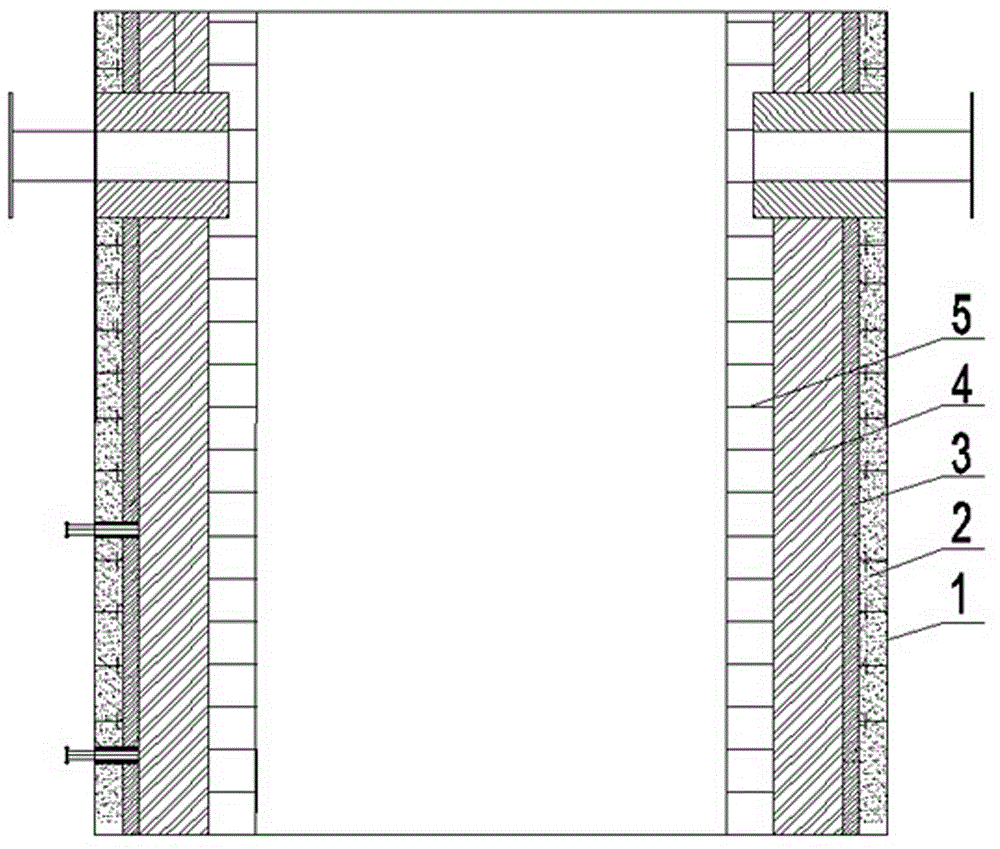

[0032] In order to overcome the deficiencies of the prior art, the present invention provides a high-temperature-resistant and corrosion-resistant furnace body for a fluidized chlorination furnace as shown in the figure, including a shell 1, on the inner wall of the shell 1, along the axial direction of the shell There are multiple installation components in the direction, and each installation component is composed of multiple anchors, and the multiple anchors in each installation component are evenly distributed and fixed on the same circumference of the inner wall of the housing; the anchors use a diameter of 10 ㎜, the length is 100㎜ steel bar, the distance between two adjacent anchors in the same installation assembly is 300㎜, the anchor rod of the anchor is consolidated with the shell, and the anchor claw of the anchor faces the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com