A kind of alkali slag base roadbed filling material

A technology for alkali slag-based roadbed and alkali slag, which is applied in the field of building materials, can solve the problems of unqualified CBR value, environmental pollution by alkali slag, etc., and achieves the effects of qualified engineering indicators, overcoming serious environmental pollution, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

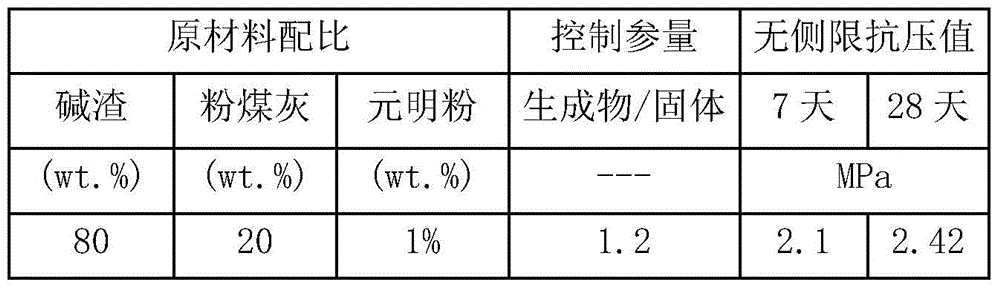

Embodiment 1

[0015] Get the actual required amount of alkali slag and fly ash for construction projects, and mix evenly with 80% (quality) of alkali slag and 20% (quality) of fly ash, and then add 1% ( mass) of sodium sulfate as an active agent, and then stir evenly to obtain a kind of alkali slag-based roadbed filling material.

[0016] The unconfined compressive strength measurement result of a kind of alkali slag base subgrade filling material that the present embodiment makes is as follows:

[0017] An alkali slag-based subgrade filling material prepared in this example has high compressive strength, and the compressive strength of the 28-day-old sample is increased compared with that of the 7-day-old sample. Table 1 lists the unconfined compressive strength of an alkali slag-based roadbed filling material prepared in this example. The measured unconfined compressive strength is 2.1MPa-2.42MPa, which can meet the corresponding engineering bearing capacity requirements such as roadbed ...

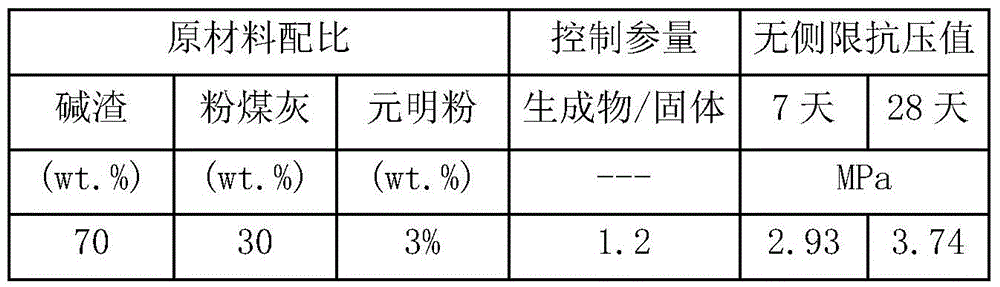

Embodiment 2

[0021] Get the actual required amount of alkali slag and fly ash for construction projects, and mix evenly with 70% (quality) alkali slag and 30% (quality) fly ash, and then add 3% ( mass) of sodium sulfate as an active agent, and then stir evenly to obtain a kind of alkali slag-based roadbed filling material.

[0022] The unconfined compressive strength measurement result of a kind of alkali slag base subgrade filling material that the present embodiment makes is as follows:

[0023] An alkali slag-based subgrade filling material prepared in this example has high compressive strength, and the compressive strength of the 28-day-old sample is increased compared with that of the 7-day-old sample. Table 2 lists the unconfined compressive strength of a kind of alkali slag-based roadbed filling material prepared in this embodiment. The measured unconfined compressive strength values range from 2.93MPa to 3.74MPa, which can meet the corresponding engineering bearing capacity requ...

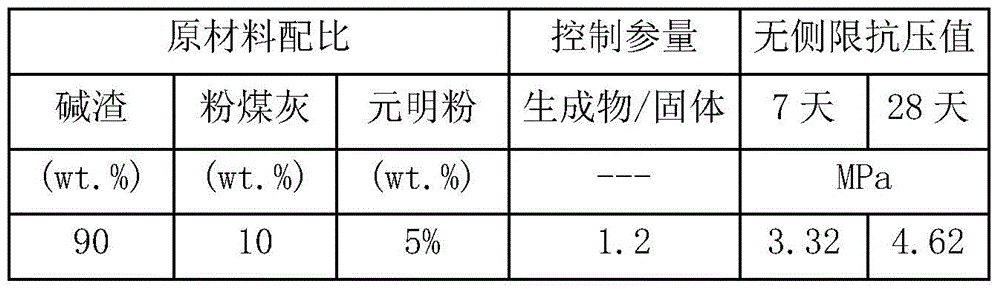

Embodiment 3

[0027] Get the actual required amount of alkali slag and fly ash for construction projects, and mix evenly with 90% (quality) alkali slag and 10% (quality) fly ash, then add 5% ( mass) of sodium sulfate as an active agent, and then stir evenly to obtain a kind of alkali slag-based roadbed filling material.

[0028] The unconfined compressive strength measurement result of a kind of alkali slag base subgrade filling material that the present embodiment makes is as follows:

[0029] An alkali slag-based subgrade filling material prepared in this example has high compressive strength, and the compressive strength of the 28-day-old sample is increased compared with that of the 7-day-old sample. Table 3 lists the unconfined compressive strength of an alkali slag-based roadbed filling material prepared in this example. The measured unconfined compressive strength is 3.32MPa-4.62MPa, which can meet the corresponding engineering bearing capacity requirements such as roadbed filling. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com