Biosynthetic method of high purity L-alpha-amino acid

A biosynthesis and amino acid technology, applied in the direction of fermentation, can solve the problems of harsh reaction conditions, difficult separation and purification, and complicated process, and achieve the effects of low equipment requirements, wide source of raw materials, and simple method steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

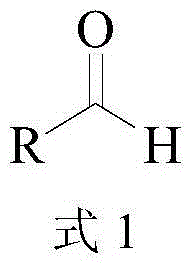

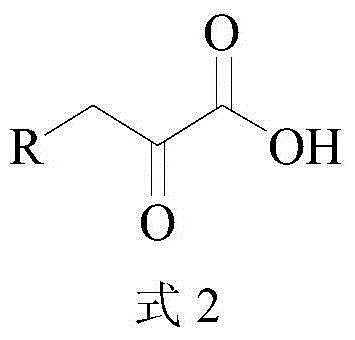

Method used

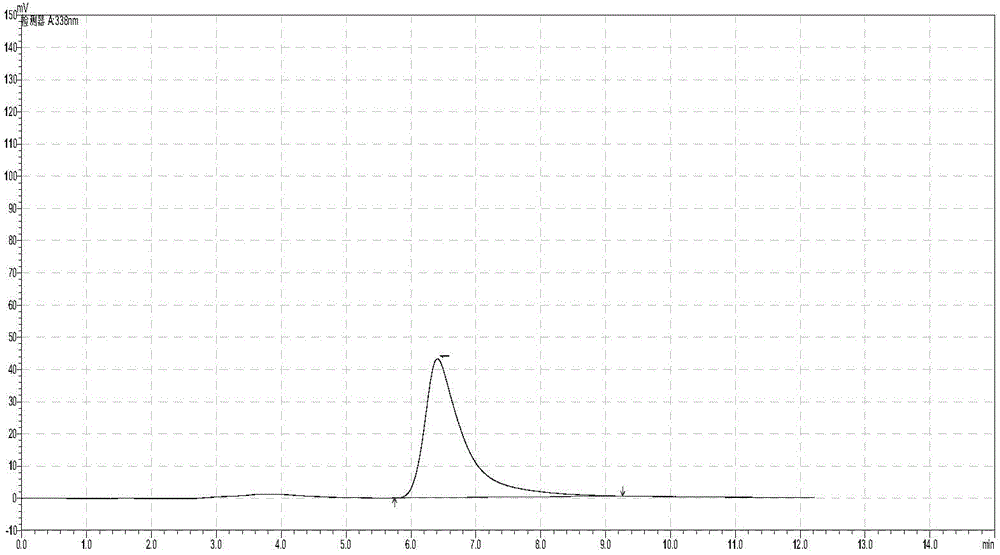

Image

Examples

Embodiment 1

[0041] Take L-norvaline as an example:

[0042] Take 63.0g of anhydrous glycine and add an appropriate amount of deionized water to dissolve it, then add 97% 60mL propionaldehyde solution and dissolve it with 3.0mol / L ammonia water to adjust the pH to 7.50±0.05, vacuum filter to remove insoluble matter, and set the volume to 1000mL. Cast immobilized L-threonine aldolase 37500U / mol (propionaldehyde), immobilized L-threonine deaminase 25000U / mol (propionaldehyde), control reaction temperature 30°C, use 3.0mol / L ammonia water Keep the pH at 7.50±0.05, and when the molar conversion rate of glycine in the liquid phase is ≥99%, filter out the conversion termination solution. After separation and purification by ion exchange chromatography, 1156 mL of a solution containing 88.44 g of 2-pentanuonic acid was obtained, with a yield of 95.30%. The chromatographic collection liquid was then adjusted to pH 7.50±0.05 with 3.0mol / L ammonia water, and then immobilized leucine dehydrogenase w...

Embodiment 2

[0053] Take 63.0g of anhydrous glycine and add an appropriate amount of deionized water to dissolve it, then add 97% 60mL propionaldehyde solution and dissolve it with 3.0mol / L ammonia water to adjust the pH to 7.50±0.05, vacuum filter to remove insoluble matter, and set the volume to 1000mL. Cast immobilized L-threonine aldolase 37500U / mol (propionaldehyde), immobilized L-threonine deaminase 25000U / mol (propionaldehyde), control reaction temperature 30°C, use 3.0mol / L ammonia water Keep the pH at 7.50±0.05, when the molar conversion rate of glycine in the liquid phase is ≥99%, filter out the conversion termination solution. After separation and purification by ion exchange chromatography, 1156 mL of a solution containing 88.44 g of 2-pentanuonic acid was obtained, with a yield of 95.30%. The chromatographic collection liquid was then adjusted to pH 7.50±0.05 with 3.0mol / L ammonia water, and immobilized leucine dehydrogenase was added at a ratio of 12000U / mol (2-pentanuonic ac...

Embodiment 3

[0055] Take 63.0g of anhydrous glycine and add an appropriate amount of deionized water to dissolve it, then add 97% 60mL propionaldehyde solution and dissolve it with 3.0mol / L ammonia water to adjust the pH to 7.50±0.05, vacuum filter to remove insoluble matter, and set the volume to 1000mL. Cast immobilized L-threonine aldolase 37500U / mol (propionaldehyde), immobilized L-threonine deaminase 25000U / mol (propionaldehyde), control reaction temperature 30°C, use 3.0mol / L ammonia water Keep the pH at 7.50±0.05, and when the molar conversion rate of glycine in the liquid phase is ≥99%, filter out the conversion termination solution. After separation and purification by ion exchange chromatography, 1156 mL of a solution containing 88.44 g of 2-pentanuonic acid was obtained, with a yield of 95.3%. The chromatographic collection liquid was then adjusted to pH 7.50±0.05 with 3.0mol / L ammonia water, and immobilized leucine dehydrogenase was added at a ratio of 12000U / mol (2-pentanuonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com