Zinc-containing pyrite cinder processing method

A technology of sulfuric acid slag and a treatment method, which is applied in the field of beneficiation and metallurgy, can solve the problem that the valuable components of sulfuric acid slag resources are not well utilized, and achieve the effects of low cost, reduced pollution and improved recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

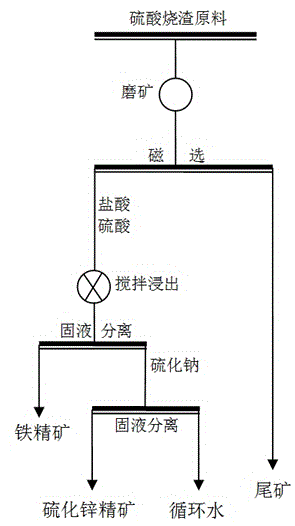

[0028] The treatment method of zinc-containing sulfuric acid slag described in this embodiment (such as figure 1 shown), specifically including the following steps: Grinding 1 ton of sulfuric acid slag raw materials containing 45.52% iron, 2.48% zinc, and 1.84% sulfur until the fineness is less than 74μm, accounting for 90%, and then the Magnetic separation is carried out in a 0.4T magnetic separator, which is a rough separation; the obtained iron coarse concentrate is desulfurized, and the concentration of the iron coarse concentrate obtained by magnetic separation is concentrated to 40%, and then added to the mixing tank, adding 1kg Hydrochloric acid and 1kg sulfuric acid carried out stirring acid hydrolysis at normal temperature for 8 minutes, and the stirring speed was 150rpm. After the solid-liquid separation, the high-quality iron ore concentrate iron grade obtained was 57.18%, and the recovery rate was 70.53%. Add 20g / L of sodium sulfide is used to sulfide and precipit...

Embodiment 2

[0030] The treatment method of zinc-containing sulfuric acid slag described in this embodiment specifically comprises the following steps: 1 ton of sulfuric acid slag containing 50.15% iron, 2.92% zinc and 2.17% sulfur is ground to a fineness of After less than 74μm accounts for 85%, magnetic separation is carried out in a magnetic separator with a magnetic field strength of 0.3T, which is a rough separation; the obtained iron coarse concentrate is desulfurized, and the concentration of the iron coarse concentrate obtained by magnetic separation is concentrated to After 33%, add 1.2kg of hydrochloric acid and 1.2kg of sulfuric acid to the stirring tank for 10 minutes of stirring and acidolysis at room temperature. The stirring speed is 180rpm. After solid-liquid separation, the grade of high-quality iron concentrate obtained is 58.23% and the recovery rate is 72.85%. Add 25g / L of sodium sulfide to the liquid obtained by solid-liquid separation to carry out sulfidation and preci...

Embodiment 3

[0032] The treatment method of zinc-containing sulfuric acid slag described in this embodiment specifically includes the following steps: grinding 1 ton of sulfuric acid slag raw materials containing 52.87% iron, 3.25% zinc, and 2.81% sulfur until the fineness is less than After 74μm accounts for 80%, magnetic separation is carried out in a magnetic separator with a magnetic field strength of 0.2T, which is a rough separation; desulfurization operation is performed on the obtained iron coarse concentrate, and the concentration of the iron coarse concentrate obtained by magnetic separation is concentrated to 30 After %, to add the mixing tank, add 1.5kg hydrochloric acid and 1.5kg sulfuric acid to carry out stirring and acidolysis at normal temperature for 9 minutes, the stirring speed is 200rpm, after the solid-liquid separation, the iron-containing grade of high-quality iron concentrate obtained is 60.25%, and the recovery rate is 75.92%; Add 30g / L of sodium sulfide to the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com