Sample extraction, purification and concentration integrated device and sample pretreatment method

A sample and extraction technology, applied in the field of purification and concentration integrated device, sample extraction, and sample pretreatment, can solve the problems of insufficient intelligent pressure control of the extraction device, heavy workload of operators, and no sample extraction system, etc. The effect of low equipment cost, improved evaporation efficiency and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

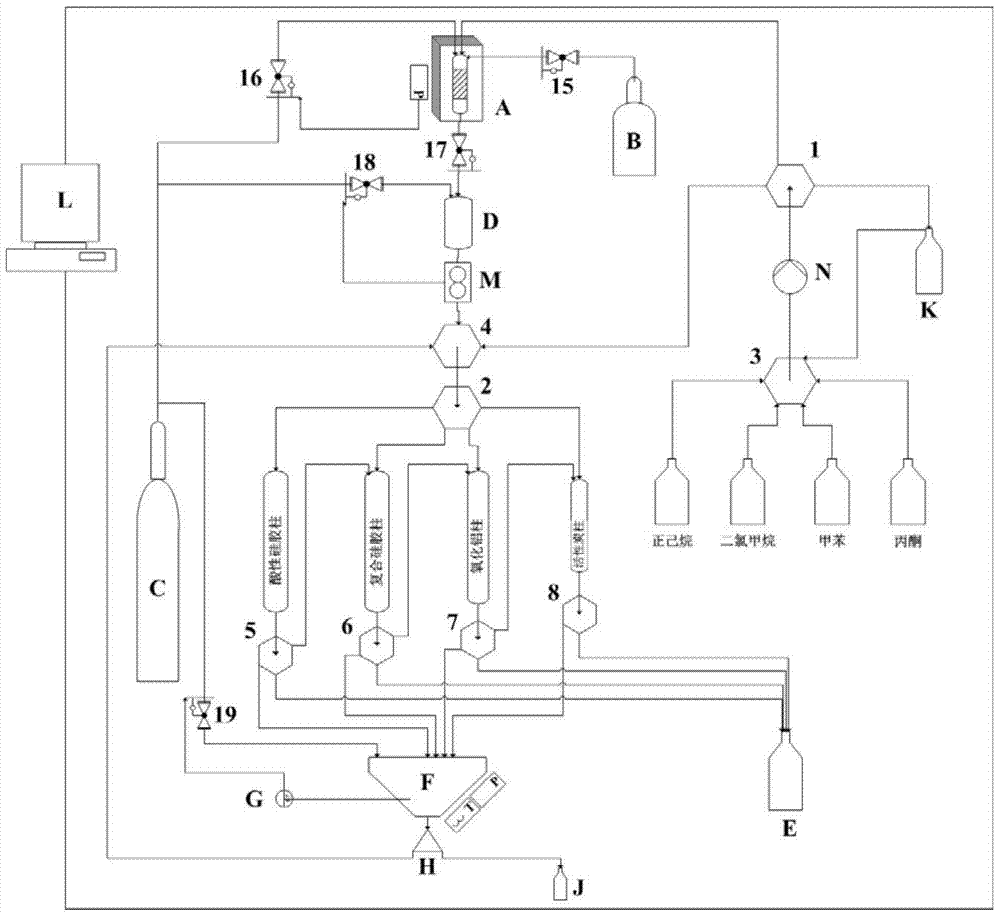

[0039] Such as figure 1 Shown is a schematic diagram of the integrated device for sample extraction, purification and concentration of the present invention.

[0040] The invention includes a solvent system, a sample extraction system, a sample purification system, a sample concentration system and a computer. in:

[0041] Solvent system: In this embodiment, four commonly used organic solvents, n-hexane, methylene chloride, toluene and acetone, are taken as examples. The solvent system is selected and distributed by the first solvent selection valve 1 and the first solvent switching valve 3. According to the needs of the system extraction or purification steps, the target solvent is drawn by the pump N; if a mixed solvent is required, a certain amount of solvent is drawn by the pump N Enter the premix bottle K for premixing and then transfer (solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com