Preparation method of precious-metal-free high-activity photocatalytic-water-splitting hydrogen-producing catalyst

A catalyst and high-activity technology, applied in the field of photocatalysis, can solve the problems of restricting industrial applications, and achieve the effects of small investment, easy preparation process, and high hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

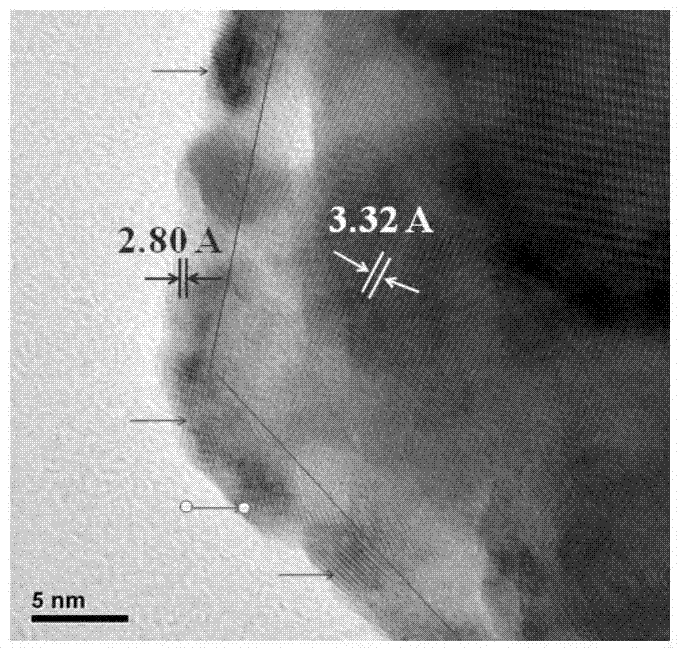

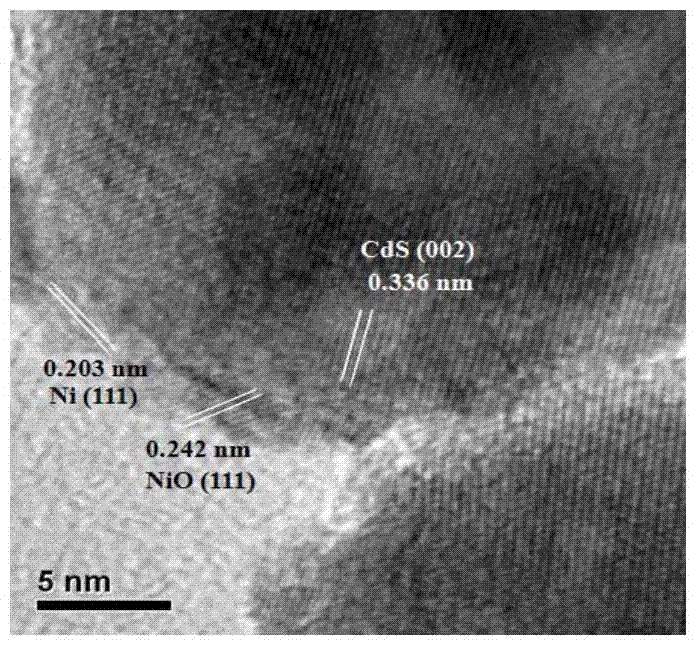

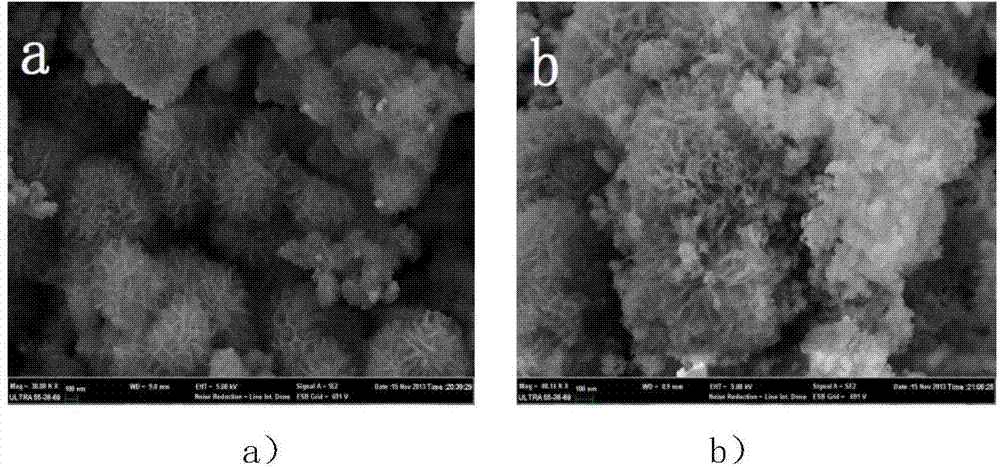

[0025] This example relates to a noble metal-free high-activity photocatalyst for hydrogen production from water splitting NiO x -CdS, its preparation method specifically comprises the following steps:

[0026] 1. 200ml of sodium sulfide solution (0.14mol / L) was added dropwise to 250ml of cadmium acetate solution (0.14mol / L) under stirring conditions, aged for 24h, filtered, washed, transferred to a 200ml hydrothermal kettle, heated at 200°C for 24h, naturally Cool, filter and wash, and dry at 40°C to obtain CdS for future use.

[0027] 2. Control group: Weigh 0.1g CdS, disperse it in 100ml methanol solution (30vol%), place it in a photocatalytic reactor made of Pyrex glass, add dropwise 2.0ml chloroplatinic acid (3.86*10 -3 mol / L), the amount of platinum relative to CdS is 1.5wt%. Direct external irradiation under 300W xenon lamp, use sodium nitrite (1mol / L) to filter out light with a wavelength below 400nm, and the gas produced by the photocatalytic reaction is quantitativ...

Embodiment 2

[0030] This example relates to a noble metal-free high-activity photocatalyst for hydrogen production from water splitting NiO x -CdS, its preparation method specifically comprises the following steps:

[0031] 1. 200ml of sodium sulfide solution (0.14mol / L) was added dropwise to 250ml of cadmium acetate solution (0.14mol / L) under stirring conditions, aged for 24h, filtered, washed, transferred to a 200ml hydrothermal kettle, heated at 200°C for 24h, naturally Cool, filter and wash, and dry at 40°C to obtain CdS for future use.

[0032] 2. Control group: Weigh 0.1g CdS, disperse it in 100ml methanol solution (30vol%), place it in a photocatalytic reactor made of Pyrex glass, add dropwise 2.0ml chloroplatinic acid (3.86*10 -3 mol / L), the amount of platinum relative to CdS is 1.5wt%. Direct external irradiation under 300W xenon lamp, use sodium nitrite (1mol / L) to filter out light with a wavelength below 400nm, and the gas produced by the photocatalytic reaction is quantitativ...

Embodiment 3

[0035] This example relates to a noble metal-free high-activity photocatalyst for hydrogen production from water splitting NiO x -CdS, its preparation method specifically comprises the following steps:

[0036] 1. 200ml of sodium sulfide solution (0.14mol / L) was added dropwise to 250ml of cadmium acetate solution (0.14mol / L) under stirring conditions, aged for 24h, filtered, washed, transferred to a 200ml hydrothermal kettle, heated at 200°C for 24h, naturally Cool, filter and wash, and dry at 40°C to obtain CdS for future use.

[0037] 2. Weigh 0.1g of CdS, disperse it in 100ml of methanol solution (30vol%), place it in a photocatalytic reactor made of Pyrex glass, add dropwise 2.77ml of nickel acetate solution (0.0025M), the mole of nickel relative to Cd The ratio is 0.01:1, then add 0.5g of sodium hydroxide, direct external irradiation under a 300W xenon lamp, use sodium nitrite (1mol / L) to filter out the light with a wavelength below 400nm, and use the gas produced by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com