Synthetic method of low-cost mesoporous graphite-phase carbon nitride

A technology of graphite phase carbon nitride and synthesis method, which is applied in the direction of nitrogen and non-metallic compounds, can solve problems such as difficult to find solvents, and achieve the effects of wide sources, low price and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 1.5 parts by mass of dicyandiamine to 9 parts by mass of ethylenediamine, and stir at room temperature for 5 minutes to obtain a mixed solution of dicyandiamine and ethylenediamine;

[0030] (2) Drop the mixed solution obtained in step (1) into 1 mass part of SBA-15 powder, and stir for 5 minutes to form a transparent semi-fluid, and then age for 4 hours;

[0031] (3) heat the transparent semi-fluid obtained in step 2 in an oil bath at 90°C, and dry overnight to obtain a blocky orange-yellow solid;

[0032] (4) Grinding the orange-yellow solid obtained in step (3) and roasting it in a tube furnace with a nitrogen atmosphere, the heating program conditions are as follows: from room temperature to 2.5 ° C min -1 The heating rate was raised to 550°C, and then kept at this temperature for 4 hours, and a black solid was obtained after cooling down;

[0033] (5) Disperse the black solid obtained in step (4) in 200 parts by mass of 5wt% HF (~4molL -1 ) in aqueous sol...

Embodiment 2

[0038] (1) Add 2.0 parts by mass of dicyandiamine to 9 parts by mass of ethylenediamine, and stir at room temperature for 8 minutes to obtain a mixed solution of dicyandiamine and ethylenediamine;

[0039] (2) Drop the mixed solution obtained in step (1) into 1 mass part of SBA-15 powder, and stir for 8 minutes to form a transparent semi-fluid, and then age for 6 hours;

[0040] (3) heat the transparent semi-fluid obtained in step 2 in an oil bath at 90°C, and dry overnight to obtain a blocky orange-yellow solid;

[0041] (4) Grinding the orange-yellow solid obtained in step (3) and roasting it in a tube furnace with a nitrogen atmosphere, the heating program conditions are as follows: from room temperature to 2.5 ° C min -1 The heating rate was raised to 550°C, and then kept at this temperature for 4 hours, and a black solid was obtained after cooling down;

[0042] (5) the black solid that step (4) obtains is dispersed in the 5wt% NH of 200 mass parts 4 HF 2 (~4mol L -1 ...

Embodiment 3

[0047] (1) Add 2.5 parts by mass of dicyandiamine to 9 parts by mass of ethylenediamine, and stir at room temperature for 12 minutes to obtain a mixed solution of dicyandiamine and ethylenediamine;

[0048] (2) Drop the mixed solution obtained in step (1) into 1 mass part of SBA-15 powder, and stir for 12 minutes to form a transparent semi-fluid, and then age for 6 hours;

[0049] (3) heat the transparent semi-fluid obtained in step 2 in an oil bath at 90°C, and dry overnight to obtain a blocky orange-yellow solid;

[0050] (4) Grinding the orange-yellow solid obtained in step (3) and roasting it in a tube furnace with a nitrogen atmosphere, the heating program conditions are as follows: from room temperature to 2.5 ° C min -1 The heating rate was raised to 550°C, and then kept at this temperature for 4 hours, and a black solid was obtained after cooling down;

[0051] (5) the black solid that step (4) obtains is dispersed in the 5wt% NH of 200 mass parts 4 HF 2 (~4mol L -...

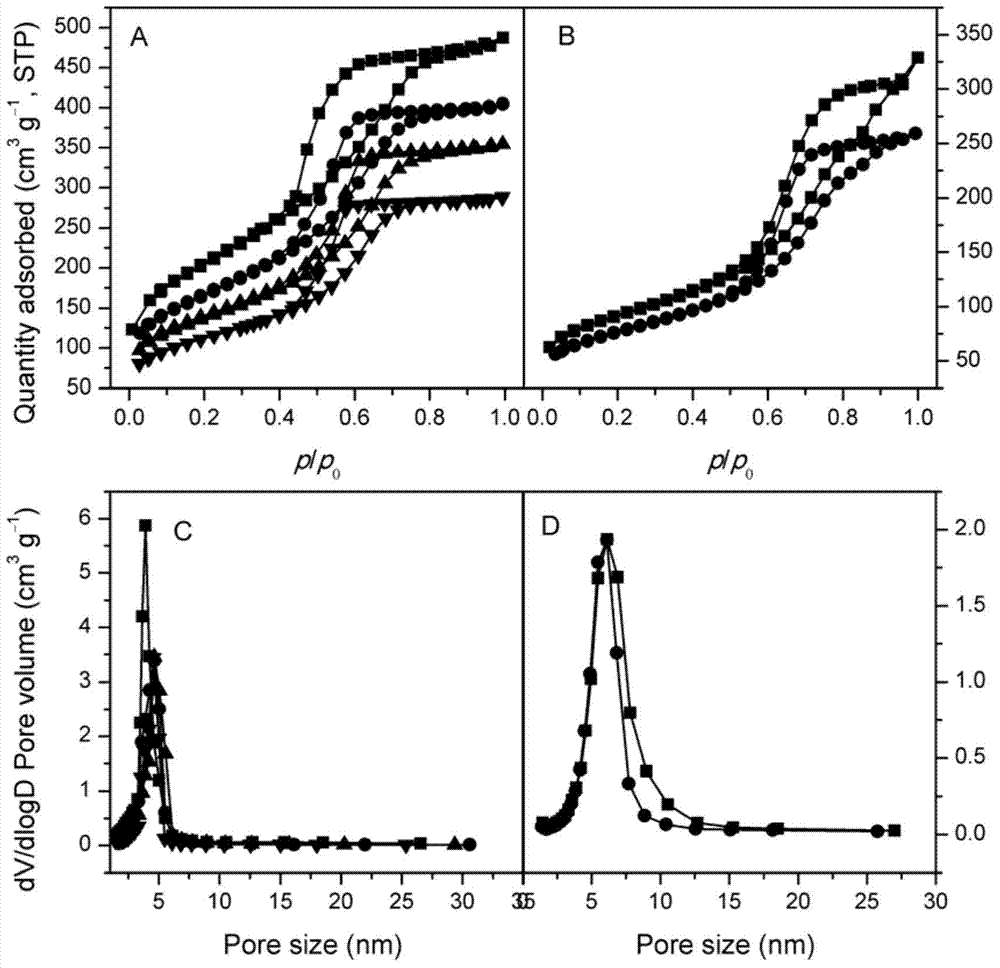

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com