Production method for preparing ammonium dihydrogen phosphate and by-product special fertilizer for chive

A technology of ammonium dihydrogen phosphate and its production method, which is applied to ammonium orthophosphate fertilizers, alkaline orthophosphate fertilizers, phosphate fertilizers, etc., can solve problems such as low purity of ammonium dihydrogen phosphate and unusable active ingredients in the filtrate, and achieve Good absorption rate, effect of increasing element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

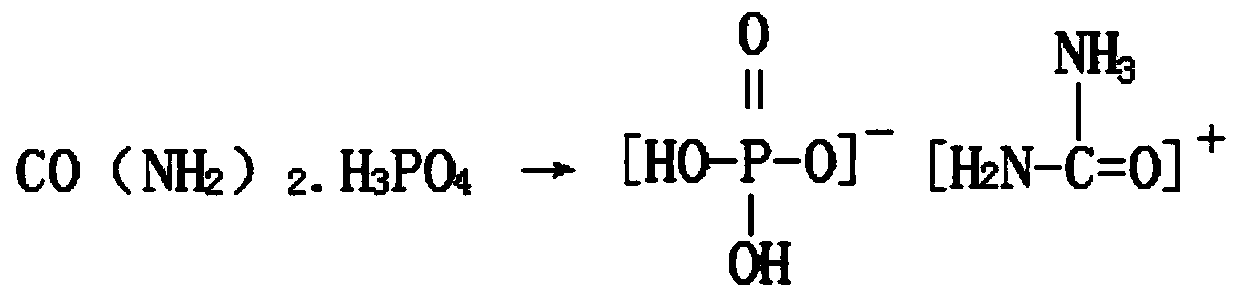

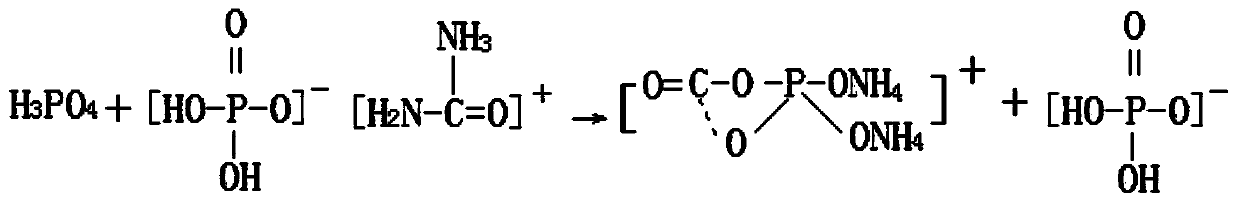

[0054] A kind of production method of preparing ammonium dihydrogen phosphate by-product shallot special fertilizer provided by this embodiment mainly comprises the following steps:

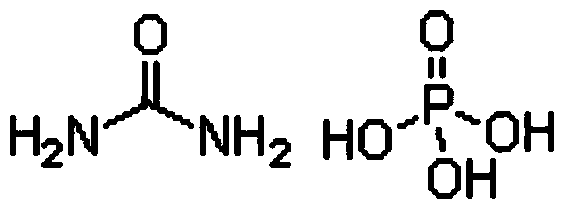

[0055] 1) Phosphoric acid and carbonamide are mixed, the molar ratio of phosphoric acid and carbonamide is 1.2:1, and the temperature is raised from 80°C to 160°C at a heating rate of 3-8°C / min, stirred and reacted for 4-5h, and separated to obtain Intermediate, then add the intermediate to the ammonia solution, the molar ratio of the intermediate to the ammonia water is 1:1.4, adjust the temperature to 50-65°C, stir and react for 2-3 hours, after the reaction, carry out cooling crystallization and filtration treatment, the crystallization temperature The temperature is 30-35°C, and the filtrate is circulated and crystallized in the cooling crystallizer, and the obtained filter cake is ammonium dihydrogen phosphate product, and the component content in the filtrate is detected;

[0056] 2) add po...

Embodiment 2

[0061] A kind of production method of preparing ammonium dihydrogen phosphate by-product shallot special fertilizer provided by this embodiment mainly comprises the following steps:

[0062] 1) Phosphoric acid and carbonamide are mixed, the molar ratio of phosphoric acid and carbonamide is 1.5:1, and the temperature is raised from 80°C to 160°C at a heating rate of 3-8°C / min, stirred for 4-5h, and separated to obtain Intermediate, then add the intermediate to the ammonia solution, the molar ratio of the intermediate to the ammonia water is 1:1.2, adjust the temperature to 50-65°C, stir and react for 2-3 hours, after the reaction, carry out cooling crystallization and filtration treatment, the crystallization temperature The temperature is 30-35°C, and the filtrate is circulated and crystallized in the cooling crystallizer, and the obtained filter cake is ammonium dihydrogen phosphate product, and the component content in the filtrate is detected;

[0063] 2) add potassium hydr...

Embodiment 3

[0068] A kind of production method of preparing ammonium dihydrogen phosphate by-product shallot special fertilizer provided by this embodiment mainly comprises the following steps:

[0069] 1) Phosphoric acid and carbonamide are mixed, the molar ratio of phosphoric acid and carbonamide is 1.3:1, and the temperature is raised from 80°C to 160°C at a heating rate of 3-8°C / min, stirred and reacted for 4-5h, and separated to obtain Intermediate, then add the intermediate to the ammonia solution, the molar ratio of the intermediate to the ammonia water is 1:1.3, adjust the temperature to 50-65°C, stir and react for 2-3 hours, after the reaction, carry out cooling crystallization and filtration treatment, the crystallization temperature The temperature is 30-35°C, and the filtrate is circulated and crystallized in the cooling crystallizer, and the obtained filter cake is ammonium dihydrogen phosphate product, and the component content in the filtrate is detected;

[0070] 2) add po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com