Biological flocculation treatment method for coal preparation waste water

A technology of biological flocculation and treatment method, which is applied in the application field of microbial science, can solve the problems of difficult degradation, high cost, and harm, and achieve the effect of no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0014] Specific Example 1 Determination of Coal Preparation Wastewater Bioflocculant Flocculation Activity

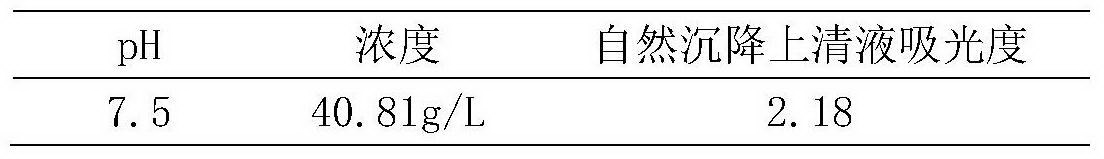

[0015] The coal slime water used was obtained from the flotation tailing coal slime water of Wangfenggang Coal Preparation Plant of Huainan Mining Group, Anhui Province. The relevant properties of slime water are shown in Table 1.

[0016] Table 1 Relevant properties of slime water

[0017]

[0018] The particle size composition and ash analysis of the coal slime are shown in Table 2.

[0019] Table 2 The particle size composition and ash analysis of coal slime

[0020]

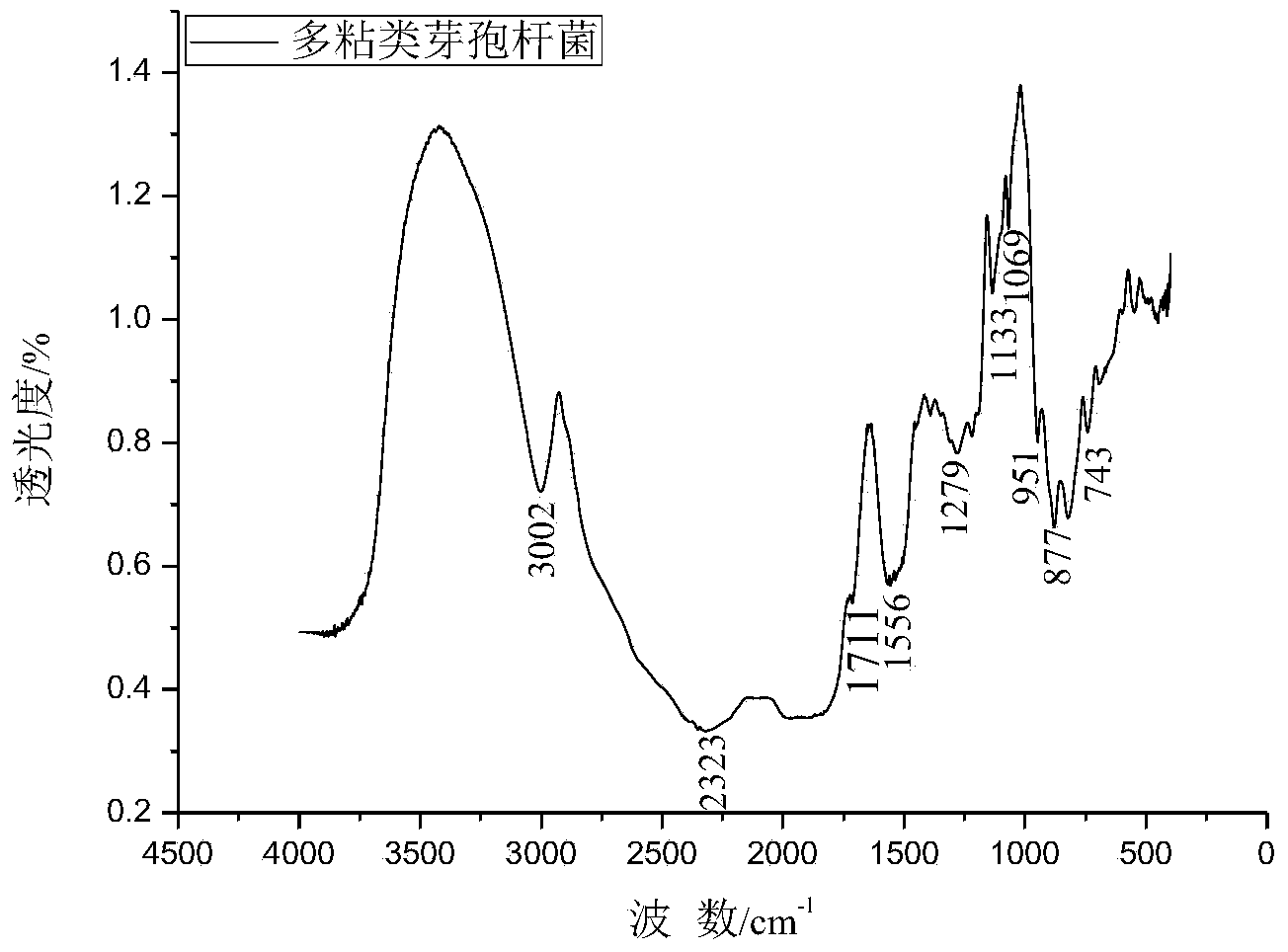

[0021] Paenibacillus polymyxa was picked from the slant culture medium with an inoculation needle and inoculated into a corresponding 250ml Erlenmeyer flask filled with 100ml liquid medium, and cultured in a 30°C constant temperature shaking incubator at a rotation speed of 160rpm for 36h.

[0022] Put 90mL of slime water in a beaker, add 4mL of W(CaCl 2 ) = 2% coagulant aid, stir at a slow s...

specific Embodiment 2

[0030] Specific example 2 Determination of flocculation activity of coal preparation wastewater biological flocculant

[0031] The slime water used was obtained from the flotation tailings slime water of Huainan Wangfenggang Coal Preparation Plant. The water-related properties of coal slime are shown in Table 1, and the particle size composition and ash analysis of coal slime are shown in Table 2.

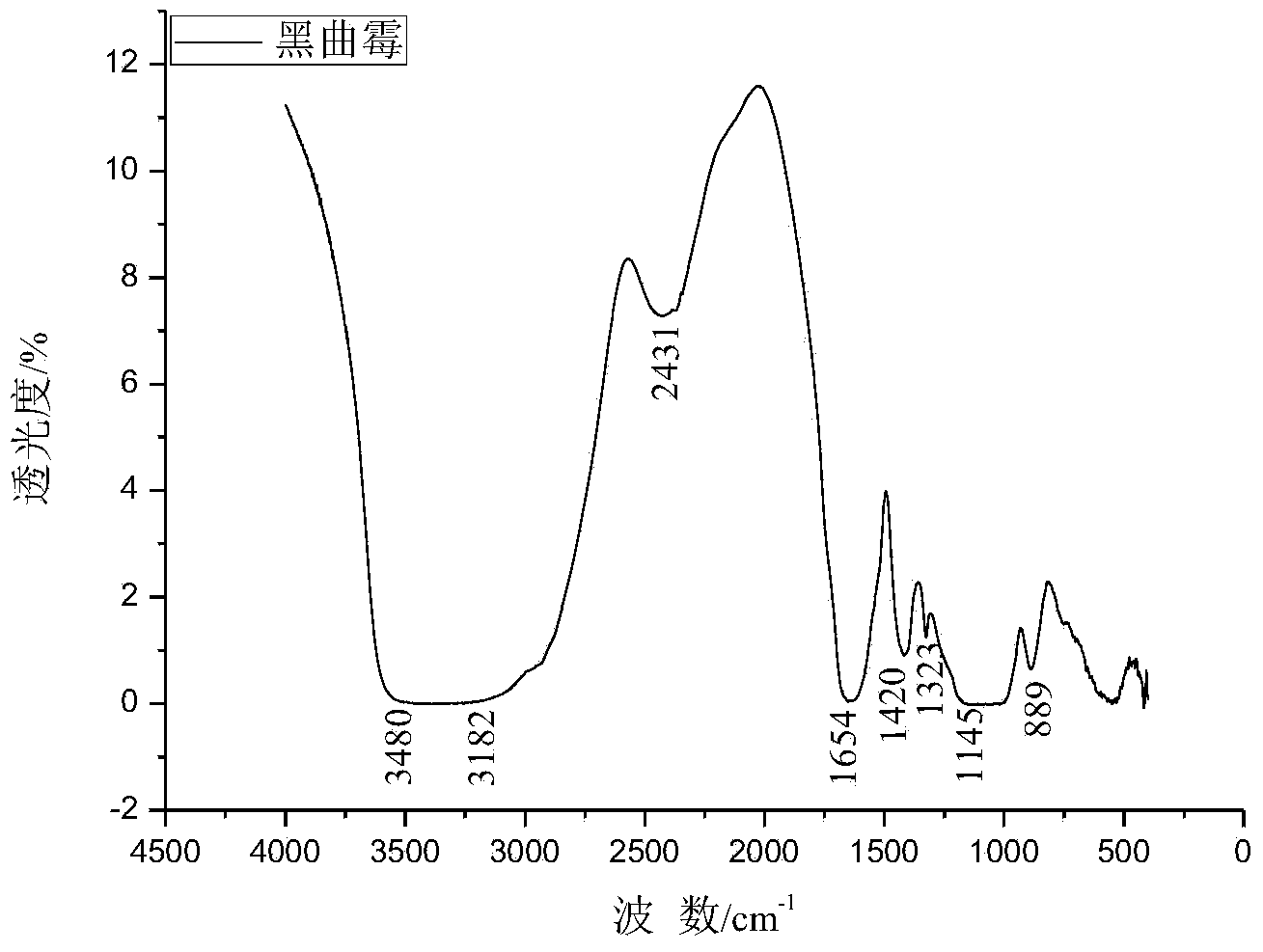

[0032] Use an inoculation needle to pick Aspergillus niger strains from the slant culture medium and inoculate them into corresponding 250ml Erlenmeyer flasks filled with 100ml liquid medium, and cultivate them in a constant temperature shaking incubator at 28°C at a rotation speed of 160rpm for 2 days.

[0033] Put 90mL of slime water in a beaker, add 4mL of W(CaCl 2 ) = 2% coagulation aid, stir slowly for 1min, then add 3mL of the broken solution of Aspergillus niger culture solution, add coal slime water to 100mL, adjust the pH value of coal slime water to 8, stir slowly with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com