Method for treating antibiotic residues by enzymic method

A technology of antibiotic dregs and enzymatic treatment, applied in the field of biomedicine, can solve the problem of high moisture content of erythromycin dregs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

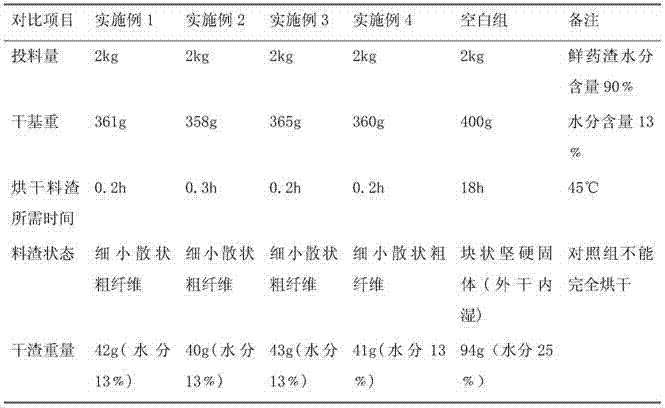

Examples

Embodiment 1

[0025] Prepare an enzyme composition, the enzyme composition includes xylanase, mannanase, protease, α-amylase, pectinase, β-glucanase, fatty alcohol polyoxyethylene ether, polypropylene Composed of amide and polyaluminum chloride; the proportion of each component of the enzyme preparation composition by weight percentage is 30% of xylanase, 10% of mannanase, 5% of protease, 20% of α-amylase, and 10% of pectinase %, β-glucanase 5%, fatty alcohol polyoxyethylene ether 5%, polyacrylamide 5%, polyaluminum chloride 10%.

[0026] The enzyme composition is mixed with water at a volume ratio of 1:50 to obtain an enzyme composition solution before application; the enzyme composition solution is evenly sprayed on the fresh antibiotic slag with a nozzle, and the antibiotic slag per ton Add 1L of enzyme preparation composition solution to the slag, stir it mechanically for 1 hour, then put the stirred antibiotic slag into the storage tank, keep the temperature at 30°C and the natural pH ...

Embodiment 2

[0028] Prepare an enzyme composition, the enzyme composition includes xylanase, mannanase, protease, α-amylase, pectinase, β-glucanase, fatty alcohol polyoxyethylene ether, polypropylene Composed of amide and polyaluminum chloride; the proportion of each component of the enzyme composition by weight percentage is 10% xylanase, 10% mannanase, 20% protease, 30% α-amylase, and 10% pectinase %, β-glucanase 5%, fatty alcohol polyoxyethylene ether 5%, polyacrylamide 3%, polyaluminum chloride 7%;

[0029] The enzyme composition is mixed with water at a volume ratio of 1:50 to obtain an enzyme composition solution before application; the enzyme composition solution is evenly sprayed on the fresh antibiotic slag with a nozzle, and the antibiotic slag per ton Add 3L of enzyme preparation composition solution to the slag, stir mechanically for 0.5h, then put the stirred antibiotic slag into the storage tank, keep the temperature at 40°C, and react for 2h at the natural pH value; after th...

Embodiment 3

[0031] Prepare an enzyme composition, the enzyme composition includes xylanase, mannanase, protease, α-amylase, pectinase, β-glucanase, fatty alcohol polyoxyethylene ether, polypropylene Composed of amide and polyaluminum chloride; the proportion of each component of the enzyme preparation composition by weight percentage is 20% of xylanase, 5% of mannanase, 20% of protease, 20% of α-amylase, and 10% of pectinase %, β-glucanase 5%, fatty alcohol polyoxyethylene ether 5%, polyacrylamide 8%, polyaluminum chloride 7%;

[0032] The enzyme composition is mixed with water at a volume ratio of 1:50 to obtain an enzyme composition solution before application; the enzyme composition solution is evenly sprayed on the fresh antibiotic slag with a nozzle, and the antibiotic slag per ton Add 5L of enzyme preparation composition solution to the slag, stir mechanically for 1 hour, then put the stirred antibiotic slag into the storage tank, keep the temperature at 50°C, and react for 4 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com