Oxygen Arc Furnace Steelmaking Method with Proper Carbon Distribution and Large Power Consumption Control

A technology of electricity consumption and electric arc furnace, which is applied in the field of electric arc furnace steelmaking, can solve the problems of large amount of carbon injection, high comprehensive cost per ton of steel, and low yield of steel materials, so as to reduce oxidation loss and iron loss , Reduce the effect of cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

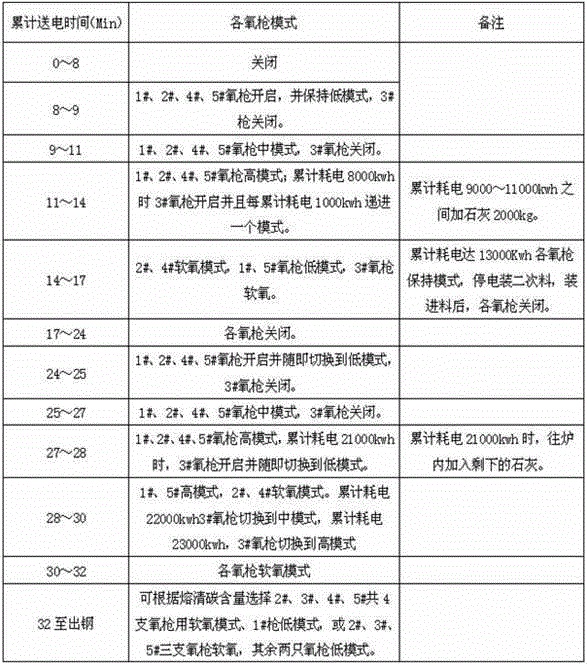

Image

Examples

Embodiment Construction

[0019] The following describes but does not limit the present invention through the description of specific embodiments of the present invention.

[0020] The present invention is specifically an oxygen electric arc furnace steelmaking method with appropriate carbon distribution and high power consumption control. The steelmaking method is a smelting method under the condition of all solid charge (scrap steel + pig iron) in an electric arc furnace. The specific steps of the method are as follows: Batching - charging - oxygen delivery - smelting - slag discharge - tapping, the above steps have been improved:

[0021] First of all, in the ingredients: pig iron is added to the scrap steel, and the amount of pig iron is controlled at 27-33% of the total weight of the furnace charge. The scrap steel material is heavy waste, medium waste, furnace charge grade scrap steel, etc., such as broken materials, baled blocks, and scraps. ; Control the appropriate amount of carbon: when batch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com