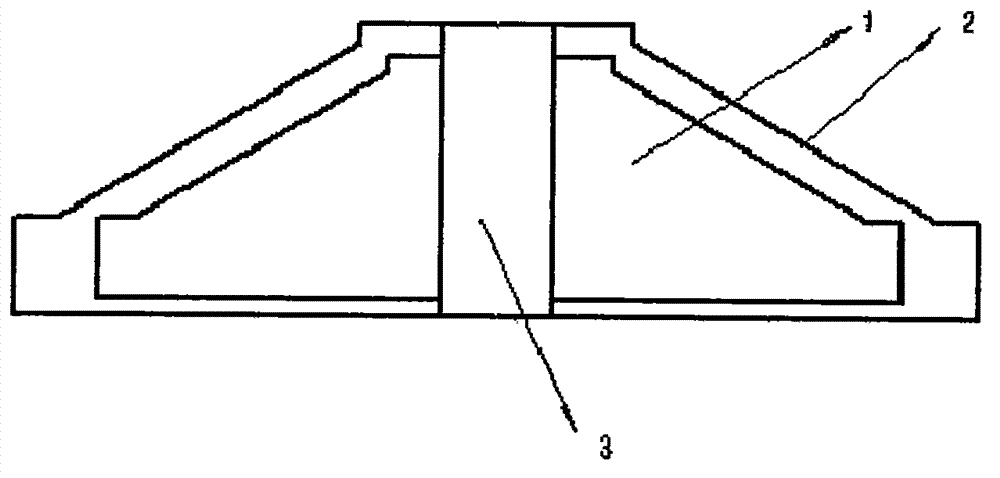

Color light storage type anchor rod plastic tray

A plastic pallet and light-storage technology, which is applied in the installation of bolts, mining equipment, earthwork drilling, etc., can solve the problems that safety hazards cannot be ignored, and there is no light-storage, light-emitting, reflective warning effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Put 100 parts of unsaturated resin 191A, 0.5 parts of benzoyl peroxide, 2 parts of decabromodiphenyl ether, 1 part of dimethylanilinium, 2 parts of antimony trioxide, and 3 parts of high-refractive aluminum-coated microbeads into the In the stirred reactor, fully stir for 45 minutes to mix;

[0024] (2) Take 10 parts of silicon micropowder, 10 parts of 20nm chopped glass fiber and stir evenly with a straight agitator; (3)

[0025] Place the slurry in step 1) and step 2) in a dipping machine and mix the gel;

[0026] (4) Take 1 part of the release agent and apply it evenly on the stainless steel mold designed according to the structure and size of the anchor tray. Place it in a stainless steel mold to ensure that the slurry is completely filled in the mold. During the molding process, ensure that the temperature difference is plus or minus 5°C, adjust the pressure of the pneumatic press to 0.8MPa, keep the heat for 6 minutes, and solidify the slurry in the mold;

...

Embodiment 2

[0031] (1) Mix 100 parts of epoxy resin, 1 part of tert-butyl methyl peroxide, 3 parts of decabromodiphenyl ether, 2 parts of dimethylanilinium, 3 parts of antimony trioxide, and 5 parts of high-refractive aluminum-plated microbeads Place in a stirring reaction kettle, fully stir for 45 minutes to mix;

[0032] (2) Stir 20 parts of silicon micropowder and 20 parts of 20nm chopped glass fiber evenly with a straight agitator; (3)

[0033] Place the slurry in step 1) and step 2) in a dipping machine and mix the gel;

[0034] (4) Take 2 parts of the release agent and apply it evenly on the aluminum mold designed according to the structure and size of the anchor tray, use the intelligent temperature controller to make the mold temperature reach 160°C, and put the gelled slurry in step 3) Accurately place in the aluminum mold to ensure that the slurry is completely filled in the mold. During the forming process, the temperature difference is guaranteed to be plus or minus 5°C. The ...

Embodiment 3

[0038] (1) Put 100 parts of vinyl resin, 0.5 parts of Akesu curing agent P-160, 3 parts of decabromodiphenyl ether, 1 part of dimethylanilinium, 2.5 parts of antimony trioxide, and 4 parts of high-refractive aluminum-plated microbeads into the In the stirred reactor, fully stir for 45 minutes to mix;

[0039] (2) Take 15 parts of silicon micropowder, 13 parts of 20nm chopped glass fiber and stir evenly with a straight agitator; (3)

[0040] Place the slurry in step 1) and step 2) in a dipping machine and mix the gel;

[0041] (4) Take 1 part of the release agent and apply it evenly on the stainless steel mold designed according to the structure and size of the anchor tray. Place in the mold to ensure that the slurry is completely filled in the mold. During the molding process, the temperature difference is guaranteed to be plus or minus 5°C. The pressure of the pneumatic press is adjusted to 0.8MPa, and the heat preservation and pressure are maintained for 5 minutes. The slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap