Method for modeling and optimizing separation process of C8-aromatics simulated moving bed

A technology for simulating moving bed and optimization method, applied in the field of modeling and optimization of C8 aromatics simulated moving bed separation process, can solve problems that are not conducive to finding the optimal operating point, triangular theory ignores axial diffusion and mass transfer resistance, and cannot be very A good description of the separation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

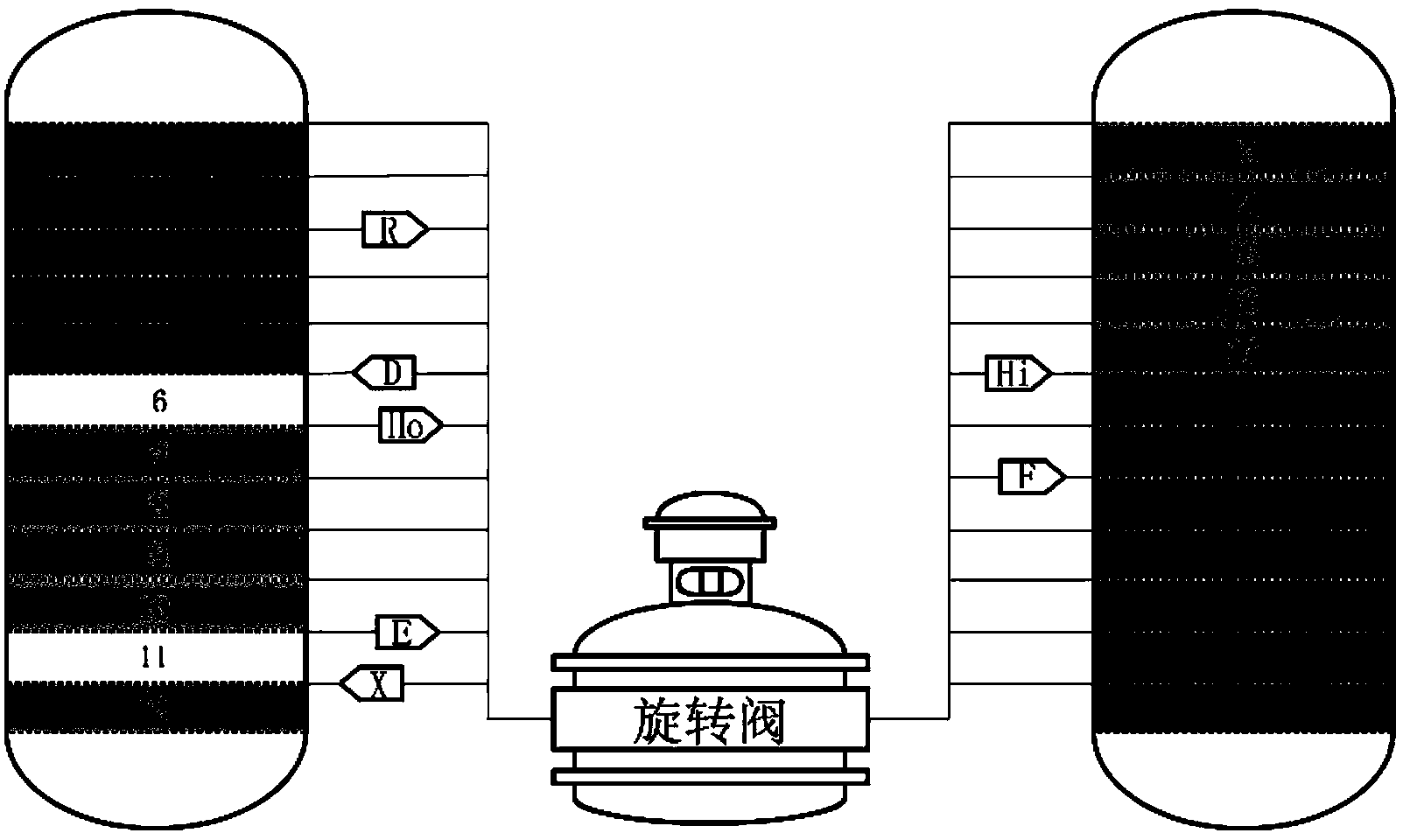

[0068] Such as figure 1 Shown, the operation schematic diagram of the simulated moving bed of xylene, this embodiment comprises the following steps:

[0069] 1 Determine the parameters at a specific temperature and pressure according to the actual simulated moving bed device: including design parameters (column length, column diameter, number of plates, etc.) and operating parameters (flow rate, step time, etc.), and set adsorption equilibrium kinetics parameter initial value;

[0070] 2 Determine the simulated moving bed chromatography model

[0071] This embodiment adopts the TMB model method, which assumes that the pressure and temperature are constant, the liquid phase is a diffuse plug flow, the solid phase is a plug flow, the mass transfer rate model adopts a linear driving force model, and the adsorption equilibrium is described by a Langmuir isotherm. And without considering the dead volume of the transmission line on the pollution of the inlet and outlet pipelines, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com