Method and device for cyclone separation and purification of radioactive waste liquid in waste liquid treatment system

A waste liquid treatment system and radioactive waste liquid technology, which are applied in the directions of radioactive purification, separation methods, chemical instruments and methods, etc., can solve the problems of cyclone-free radioactive waste liquid purification application, high cost, nuclear radiation risk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

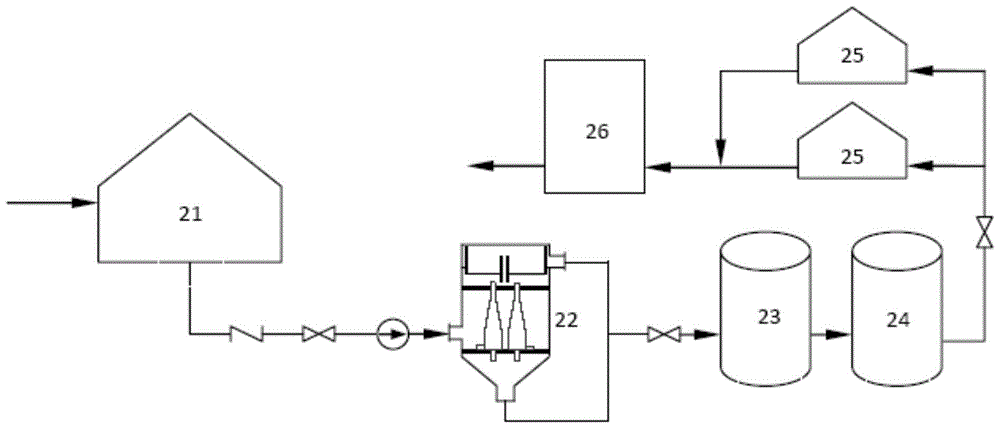

[0057] Cyclone separation and purification of radioactive waste liquid in waste liquid treatment system of nuclear power plant

[0058] 1. Implementation process

[0059] Such as figure 2 shown.

[0060] 2. Key equipment

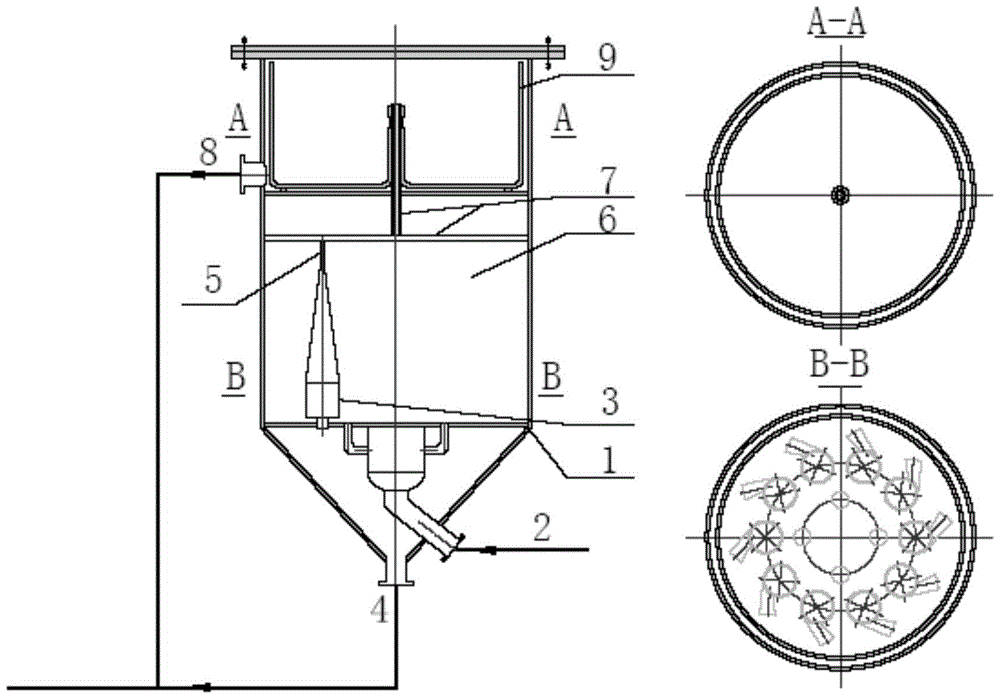

[0061] The key equipment in this process flow is a complete set of separators coupled with micro-cyclone separators and filter ash hoppers. Wherein, the parallel and inverted vertical micro-cyclone separator assembly is placed in the separator, and the filter ash hopper is placed on the top of the separator to connect the bottom flow of the micro-cyclone separator. The processing capacity of the equipment is 10m 3 / h, the external dimension is Φ600×2400. The top of the separator is closed with a tube plate type, which is convenient for the subsequent replacement of the ash hopper.

[0062] 3. Control

[0063] Under full load conditions, the feed flow rate of the separator is 10m 3 / h, the feed pressure is 0.5MPa (gauge pressure), and the operating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com