Photovoltaic thin-film solar modules and method for producing such thin-film solar modules

A solar module and solar cell technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as limited final design of thin-layer solar modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

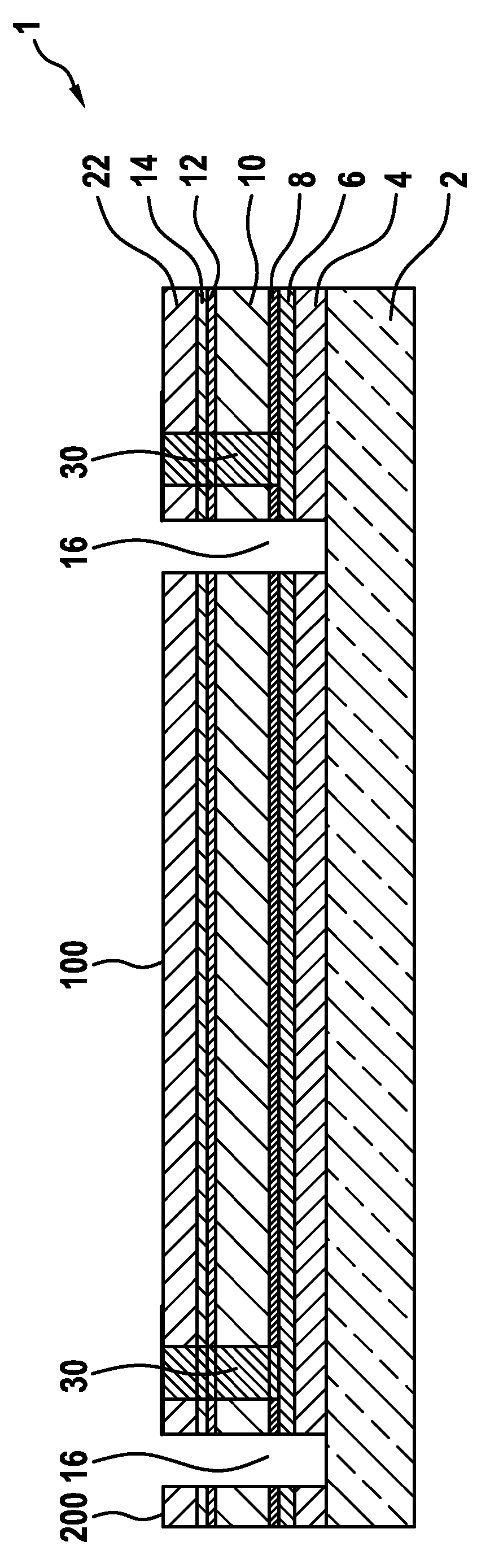

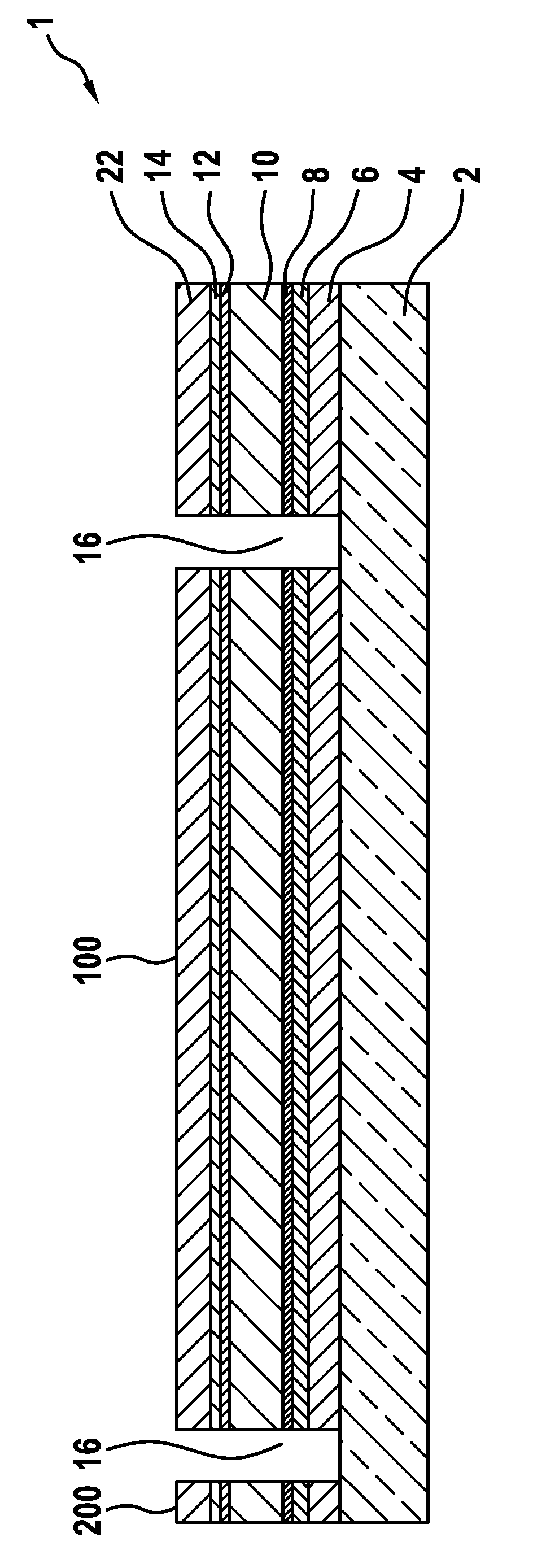

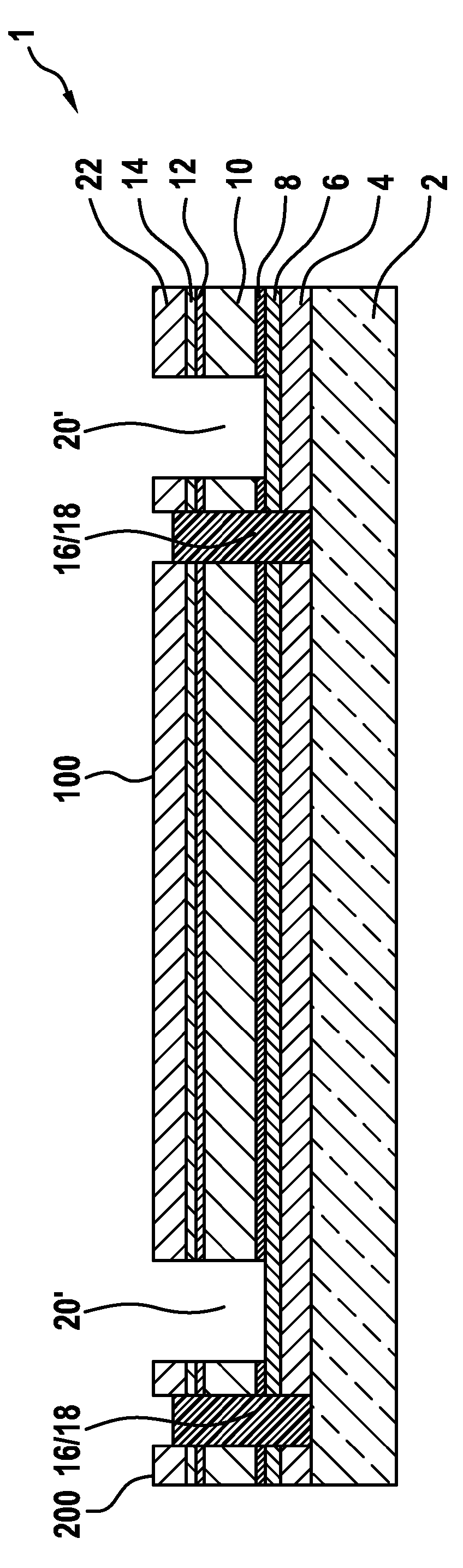

[0145] derived from figure 1A schematic cross-sectional view of an intermediate manufacturing stage of the inventive thin-film solar module 1 . A bulk back electrode layer 4 , for example composed of molybdenum, is present on the glass substrate 2 by means of thin-layer deposition. Adjacent to it is placed a bidirectionally reflective barrier layer 6, for example composed of TiN or ZrN, which can likewise be obtained by thin-layer deposition. In the embodiment shown, an ohmic contact layer 8 consisting of a metal chalcogenide such as molybdenum selenide is placed on this barrier layer 6 . As already generally stated above, the contact layer can be obtained in different ways and methods. In one development, molybdenum selenide is sputtered, for example, from a molybdenum selenide target. Alternatively, a metal layer can be applied first, which is then converted to the corresponding metal chalcogenide before and / or during the formation of the semiconductor absorber layer. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com