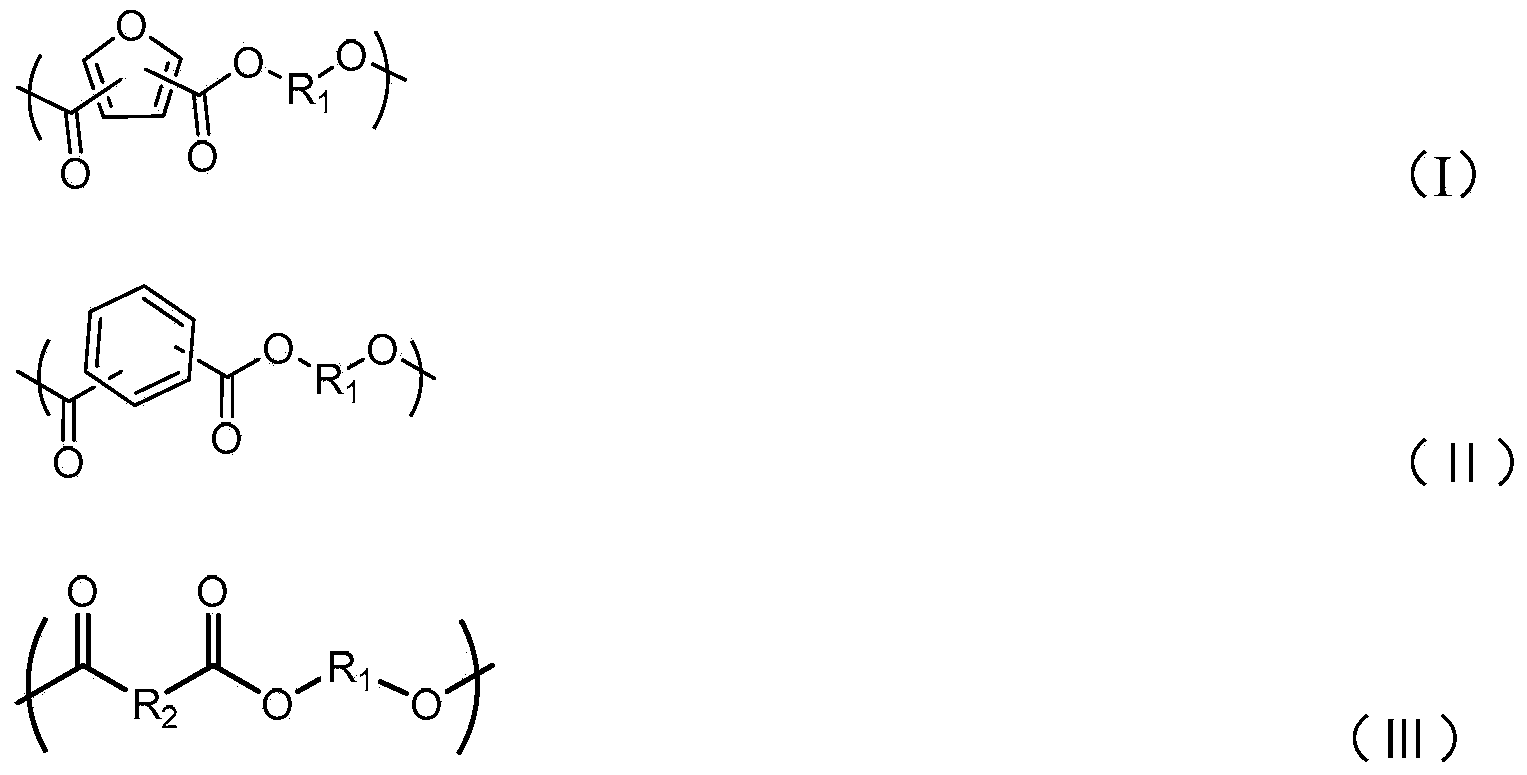

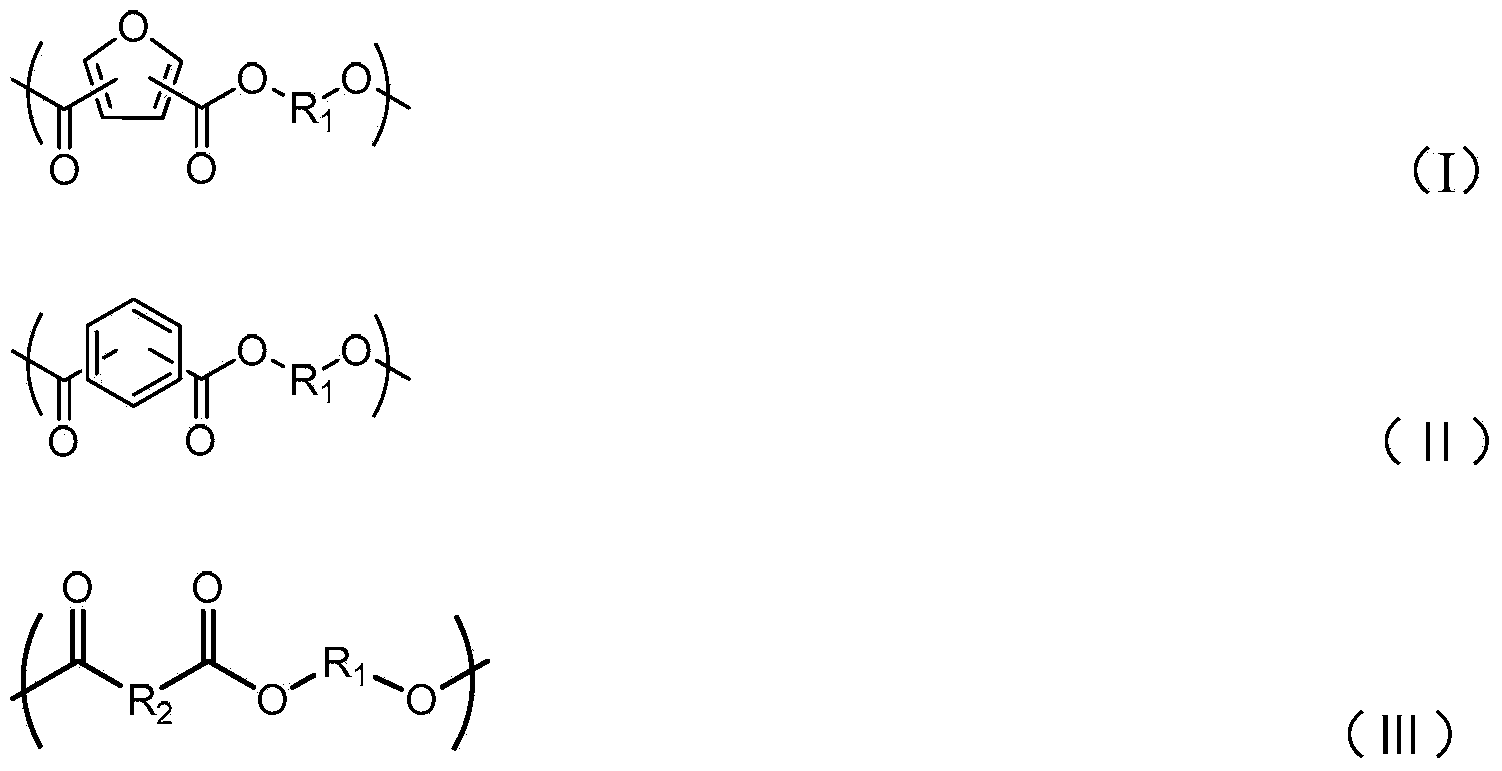

Triblock copolymer using furandicarboxylic acid flexible random copolyester as soft block and preparation method thereof

A technology of furandicarboxylic acid and copolyester, which is applied in the field of triblock copolymer and its preparation, can solve the problems of decreased environmental protection significance, loss of properties of bio-based materials, etc., and achieves commercialization, reduced dependence, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

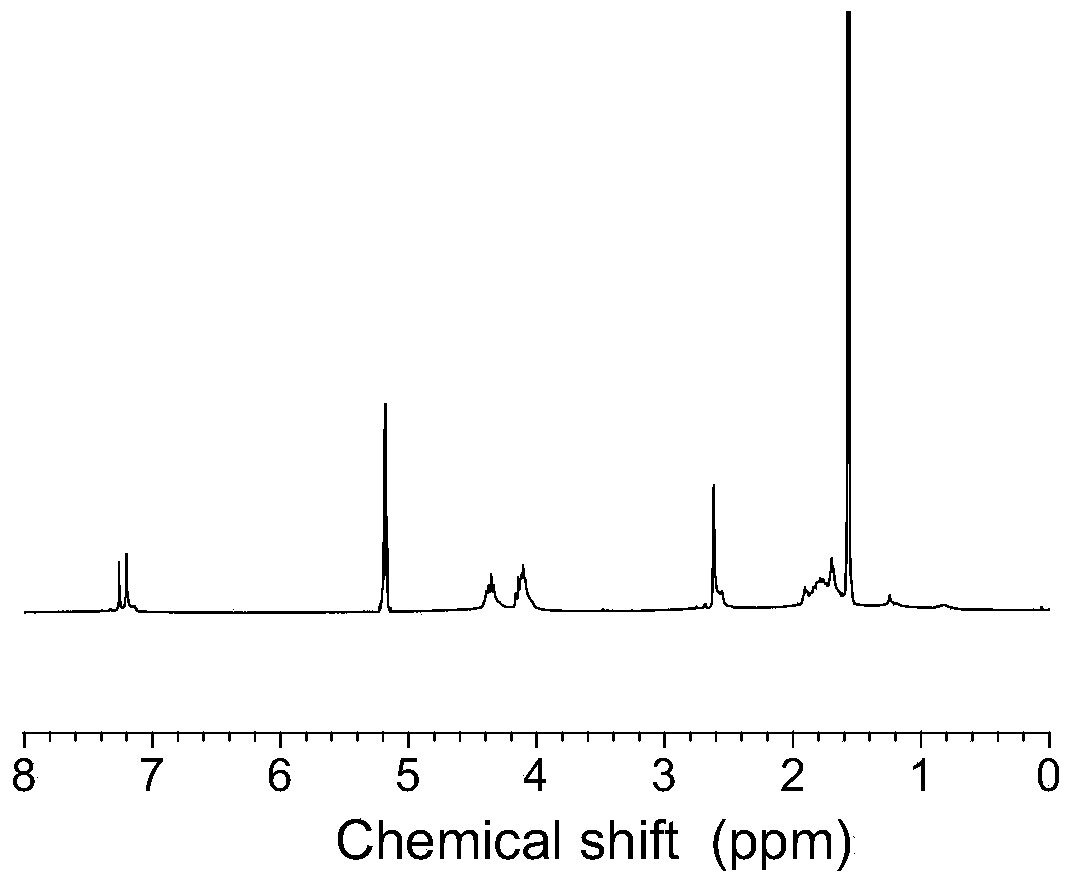

Image

Examples

Embodiment 1

[0068] (1) Add 31.2 grams (0.2mol) of 2,5-furandicarboxylic acid, 35.4 grams (0.3mol) of succinic acid, 90 grams (1mol, alkyd-acid molar ratio) of butanediol, and titanic acid into the reactor. 85 milligrams of butyl esters (accounting for 0.05mol% of the total amount of dibasic acid monomers) were subjected to an esterification reaction at 160-200°C for 4 hours (this process is a temperature-programmed process) to obtain an esterified product; 85 mg of n-butyl titanate (accounting for 0.05 mol% of the total amount of dibasic acid monomers), at 200-240°C and 10-500Pa pressure (during the reaction, the pressure is gradually reduced from 500Pa to 10Pa), the melt polycondensation reaction After 5 hours, the flexible random copolyester-poly(butylene succinate-co-2,5-butylene furandicarboxylate) of hydroxyl-terminated furandicarboxylic acid was obtained, denoted as PBS 60 f 40 ;

[0069] (2) Add 113.4 grams of L-lactide to the product of step 1, and add 0.113 grams of stannous oc...

Embodiment 2

[0071] (1) Add 23.4 grams (0.15mol) of 2,5-furandicarboxylic acid, 33.2 grams (0.2mol) of terephthalic acid, 21.9 grams (0.15mol) of adipic acid, and 135 grams (1.5 mol, alkyd acid molar ratio 3), add 170 mg of n-butyl titanate (accounting for 0.1 mol% of the total amount of dibasic acid monomers), and perform an esterification reaction at 190-230° C. for 1 hour to obtain an esterified product; Add catalyst, melt polycondensation reaction at 200-250°C, 50-500Pa pressure for 8 hours, and prepare flexible random copolyester-poly(butylene adipate-co-2) of hydroxyl-terminated furandicarboxylic acid , 5-butanediol furandicarboxylate-co-butylene terephthalate), denoted as PBA 30 f 30 T 40 ;

[0072] (2) Add 10.6 grams of D-lactide to the product of step 1, and add 53 mg of stannous octoate (0.5wt% of D-lactide), and react at 160-180°C for 0.5 hours to obtain PBA 30 f 30 T 40 A triblock copolymer PDLA-b-PBA with soft segment and poly(D-lactide) as hard segment 30 f 30 T 40 ...

Embodiment 3

[0074](1) Add 23.4 grams (0.15mol) of 2,5-furandicarboxylic acid, 21.9 grams (0.15mol) of adipic acid, 11.8 grams (0.1mol) of succinic acid, and 20.2 grams (0.1mol) of sebacic acid into the reactor ), 67.5 grams of butanediol (0.75mol, alkyd molar ratio 1.5), 142 mg of isopropyl titanate (accounting for 0.1mol% of the total amount of dibasic acid monomers), esterification reaction at 190-220°C for 1 After 1 hour, an esterification product was obtained; 110 mg of lanthanum acetylacetonate (accounting for 0.05mol% of the total amount of dibasic acid monomers) was added to the esterification product, and the melt polycondensation reaction was carried out at 220~250°C and 100~500Pa pressure for 8 hours, the flexible random copolyester of furandicarboxylic acid with terminal hydroxyl group—poly(butylene succinate-co-butylene adipate-co-butylene sebacate-co-2 , 5-butylene furandicarboxylate), recorded as PBS 20 A 30 Se 20 f 30 ;

[0075] (2) Add 40.8 grams of glycolide to the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com