Nitrogen-gas-protection-free electron-beam-cured coating/ink and preparation and curing methods thereof

An electron beam curing, nitrogen protection technology, applied in inks, polyester coatings, epoxy resin coatings, etc., can solve the problem of increasing curing costs, increasing the curing process complexity of electron beam curing coatings/inks, and increasing electron beam curing coatings/inks. Ink application range limitation and other issues, to achieve the effect of simplifying the curing process, reducing production costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

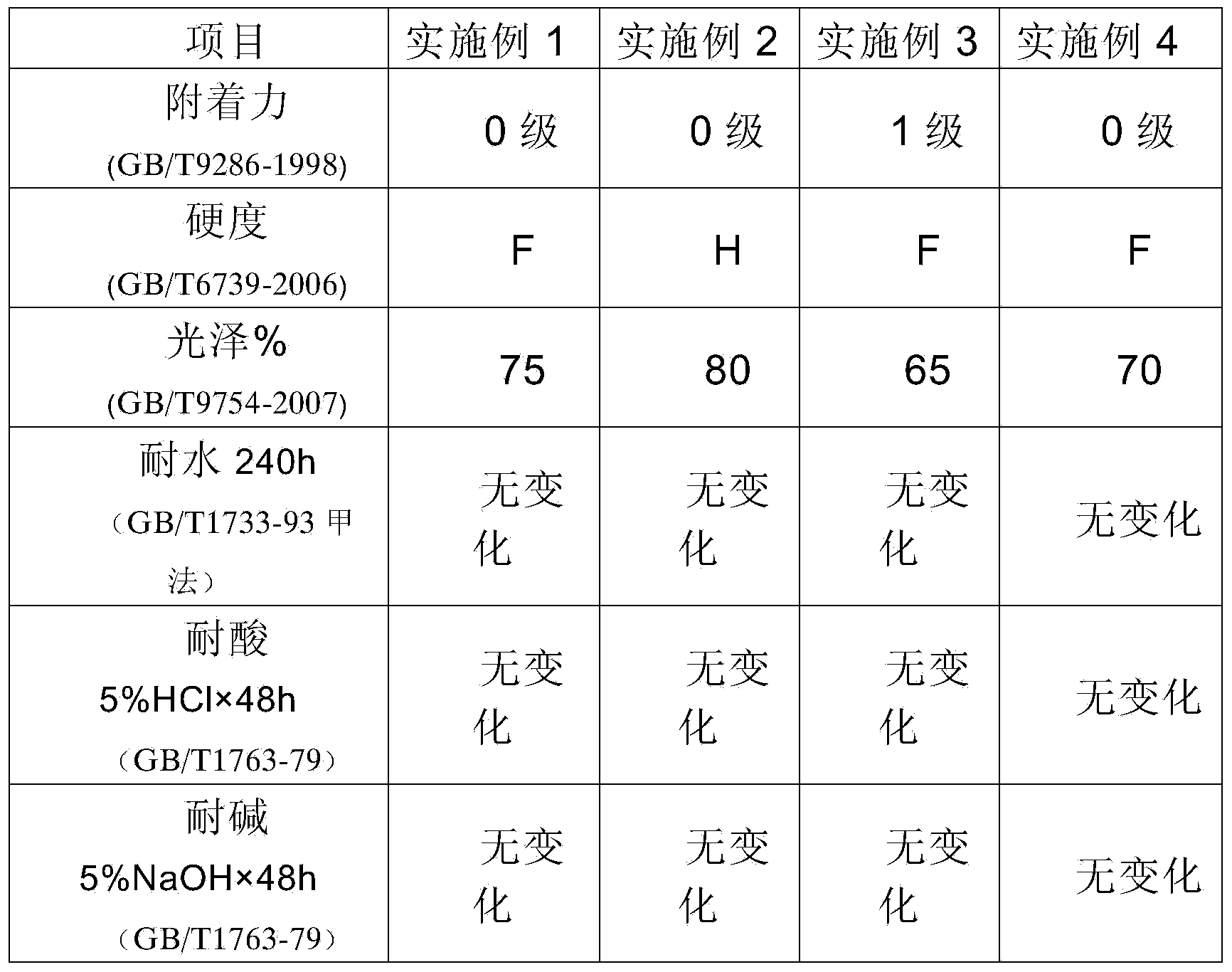

Embodiment 1

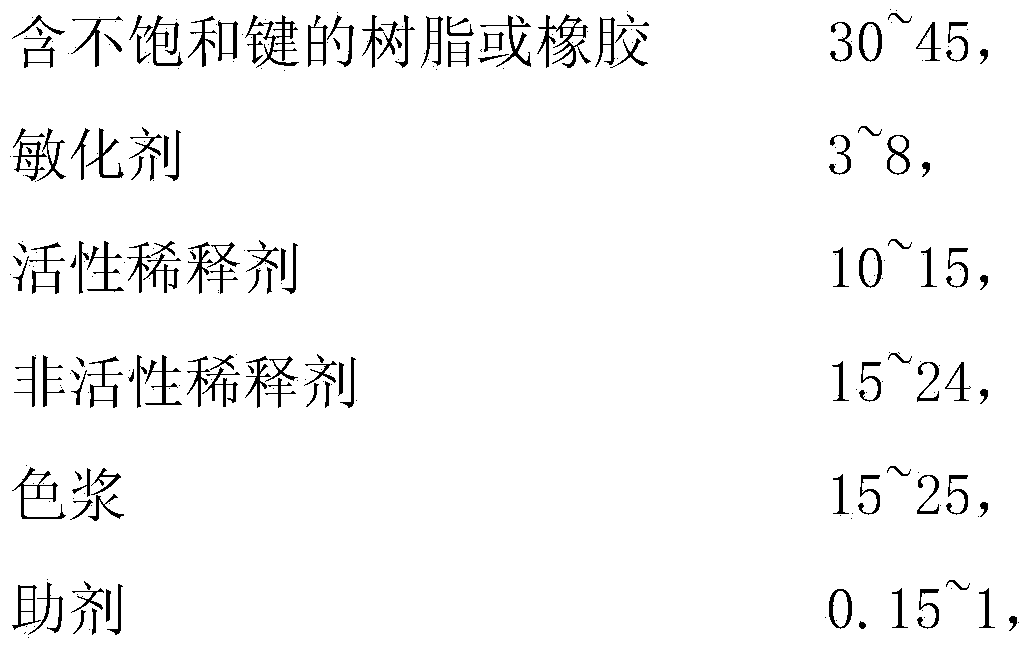

[0025] ①Place 38 parts of polyurethane-modified acrylate, 3.8 parts of trifunctional unsaturated polyester monomer, and 15.2 parts of ethoxy ethoxy ethyl acrylate in a mixing mixer in parts by mass, and stir at room temperature 15 minutes until completely dissolved into a homogeneous liquid.

[0026] ②Transfer the above homogeneous liquid into a dispersing mixer, and add 10 parts of No. 120 solvent oil, 12 parts of No. 90 gasoline, 17 parts of color paste, 0.2 parts of BYK-052, and stir at room temperature for 30 minutes to a homogeneous liquid.

[0027] ③ Add 0.6 parts of initiator DAROCUR 1173 to the above-mentioned dispersing mixer, stir at room temperature for 8 minutes, discharge, filter, and seal the package.

[0028] ④ Unpack the above-mentioned packaged paint / ink, and apply it evenly on a clean leather substrate.

[0029] ⑤Irradiate the leather substrate coated with paint / ink with UV light for 5 seconds to make the paint / ink dry.

[0030] ⑥Transfer the leather base m...

Embodiment 2

[0032] ① Place 40 parts of epoxy-modified acrylic resin, 5.8 parts of pentafunctional unsaturated polyester monomer, and 14 parts of bisphenol A ethoxylated diacrylate in a mixing agitator in parts by mass. Stir for 15 minutes until completely dissolved into a homogeneous liquid.

[0033] ②Transfer the above homogeneous liquid into a dispersing mixer, and add 10 parts of ethyl acetate, 9 parts of butyl acetate, 23 parts of color paste, 0.2 parts of BYK-168 and BYK-052, and stir for 30 minutes at room temperature to a homogeneous liquid.

[0034] ③Add 0.5 parts of initiators IRGACURE 369 and IRGACURE907 to the above-mentioned dispersing mixer, stir for 4 minutes at room temperature, discharge, filter, and seal the package.

[0035] ④ Unpack the above-mentioned packaged paint / ink, and spray it evenly on the clean tinplate substrate.

[0036] ⑤ Irradiate the tinplate base material coated with paint / ink through ultraviolet light for 8 seconds to make the paint / ink surface dry. ...

Embodiment 3

[0039] ① Put 35 parts of difunctional aliphatic urethane acrylic oligomer, 4 parts of tetrafunctional unsaturated polyester monomer, and 10 parts of tripropylene glycol diacrylate in a mixing agitator according to the number of parts by mass. Stir for 15 minutes until completely dissolved into a homogeneous liquid.

[0040] ②Transfer the above homogeneous liquid into a dispersing mixer, and add 6.2 parts of cyclohexane, 17 parts of butyl acetate, 25 parts of color paste, 0.4 parts of BYK-2155 and BYK-052, and stir for 30 minutes at room temperature to a homogeneous liquid.

[0041] ③ Add 2 parts of initiator IRGACURE 184 to the above-mentioned dispersing mixer, stir for 5 minutes at room temperature, discharge, filter, and seal the package.

[0042] ④ Unpack the above-mentioned packaged paint / ink, and apply it evenly on a clean plastic substrate.

[0043] ⑤The plastic substrate coated with paint / ink is irradiated with ultraviolet light for 3 seconds to make the paint / ink dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com