Tool prepreg for composite material mold, preparation method, application method and application

A composite material and application method technology, applied in the field of tooling prepreg of composite material mold, can solve the problems of complex curing process, high curing temperature, slow progress, etc., and achieve the effect of simplifying curing process, low specific gravity and good viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

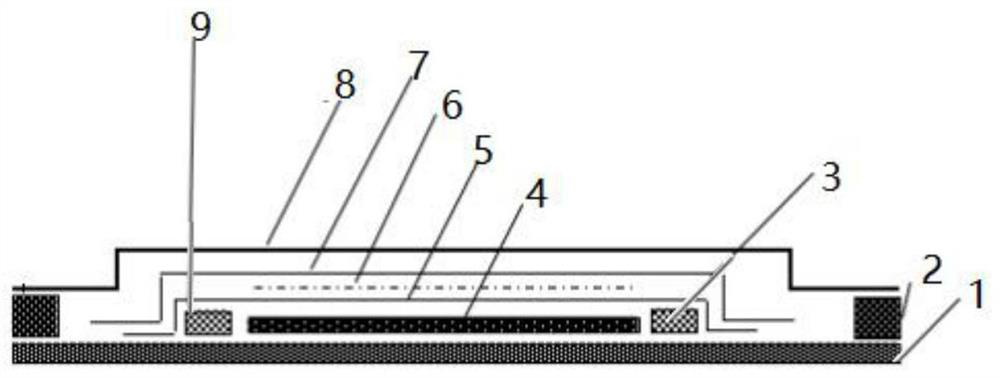

Image

Examples

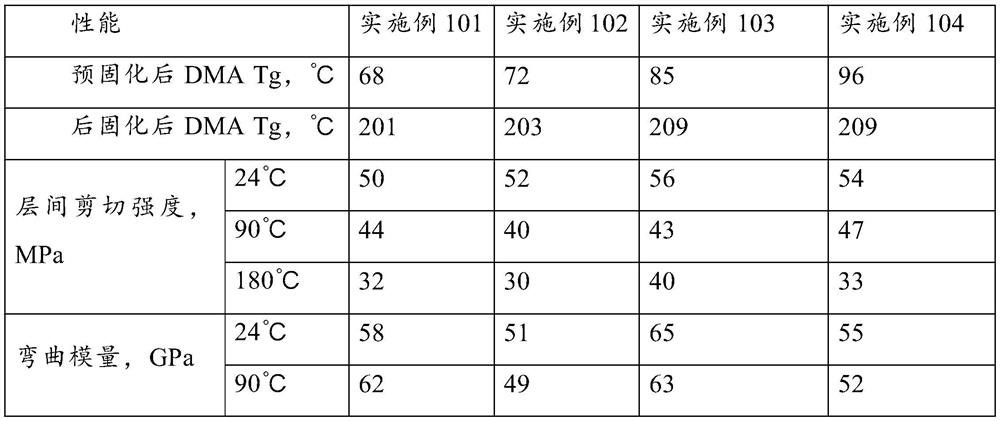

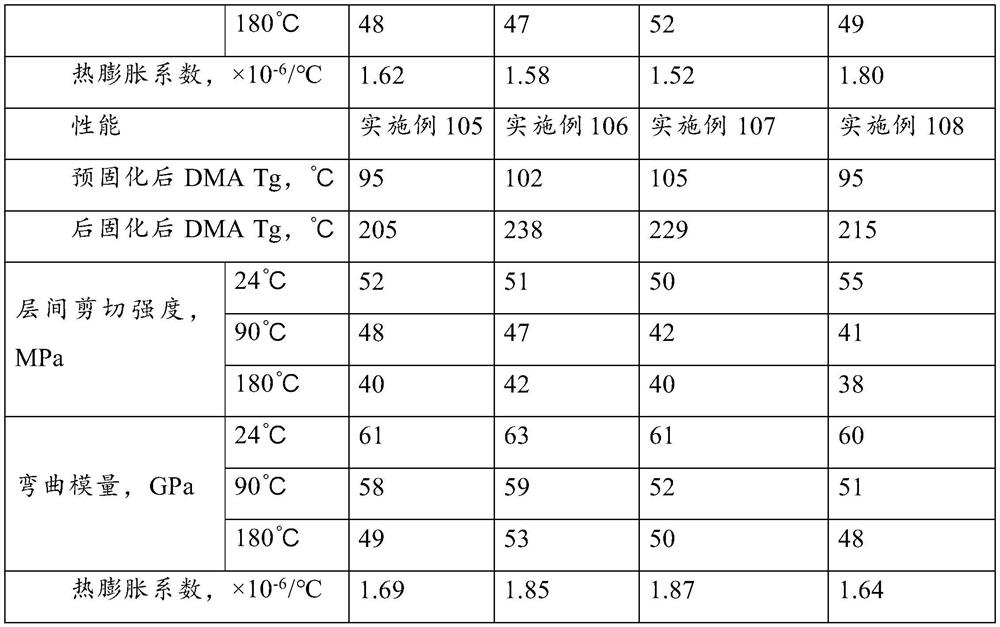

Embodiment 101

[0046] In this example, mix the resin component A and the curing agent B component uniformly to obtain SZ01 (satisfied that the viscosity at 50°C is 10Pa.s, and the gel time at 120°C is 7min), wherein the resin Component A of the mixture (with a viscosity of 10Pa.s at 50°C) accounts for 95% of the total mass of the resin, and the balance of component B of the curing agent mixture (with a viscosity of 0.1Pa.s at 25°C) (including negligible impurities, etc.). Component A of the resin mixture is bisphenol F epoxy resin (epoxy equivalent 182-195g / mol). Component B of the curing agent mixture is dicyandiamide. Then use the hot-melt method to impregnate the reinforcement material according to the corresponding process parameters. The reinforcement material is made of acrylic fiber and polypropylene fiber (each single twisted pair) fabric with a diameter of 0.1mm. After the mixture is stacked, the hot-melt prepreg temperature is 30 ℃ , to prepare the prepreg. The preparation in th...

Embodiment 102

[0058] In this example, mix resin component A and curing agent B component uniformly to obtain SZ02 (satisfied with a viscosity of 20 Pa.s at a temperature of 50°C and a gel time of 8 minutes at a temperature of 120°C), wherein the resin Component A of the mixture (with a viscosity of 20Pa.s at a temperature of 50°C) accounts for 96% of the total mass of the resin, and the balance of component B of the curing agent mixture (with a viscosity of 0.2Pa.s at a temperature of 25°C) (including negligible impurities, etc.). Component A of the resin mixture is a novolak type epoxy resin (epoxy equivalent 172-182g / mol). Curing agent mixture component B is polyamide. Then use the hot-melt method to impregnate the reinforcing material according to the corresponding process parameters. The reinforcing material is made of vinylon fiber and polyvinyl chloride fiber fabric with a diameter of 0.3mm (the three strands of each wire are formed into a thread and then woven), and the mixture is s...

Embodiment 103

[0070] In this example, mix the resin component A and the curing agent B component uniformly to obtain SZ03 (satisfied that the viscosity at 50°C is 30Pa.s, and the gel time at 120°C is 10min), wherein the resin Component A of the mixture (with a viscosity of 25Pa.s at 50°C) accounts for 97% of the total mass of the resin, and the balance of component B of the curing agent mixture (with a viscosity of 0.4Pa.s at 25°C) (including negligible impurities, etc.). Component A of the resin mixture is glycidylamine epoxy resin (epoxy equivalent 192-198g / mol). Component B of the curing agent mixture is ethylenediamine. Then use the hot-melt method to impregnate the reinforcing material according to the corresponding process parameters. The reinforcing material is a glue-dipped fiber fabric with a diameter of 0..5mm.

[0071] The performance test laminate and composite material mold preparation methods are as follows:

[0072] S21. Performance test laminated board According to the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com