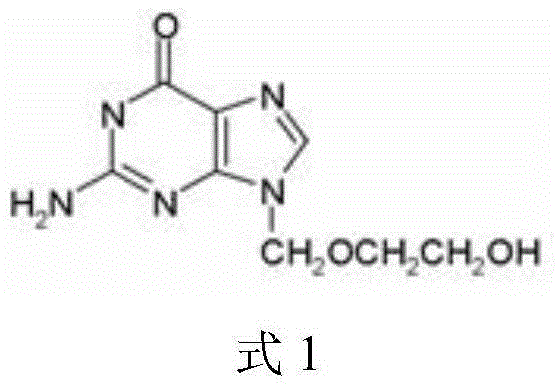

Acyclovir lyophilized formulation for injection and preparation method acyclovir lyophilized formulation

A technology for freeze-dried preparations and injections, which is applied in the direction of freeze-dried transportation, medical preparations of non-active ingredients, antiviral agents, etc. It can solve problems such as difficulty in ensuring long-term stability, achieve good clarity, low impurity content, Quality Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

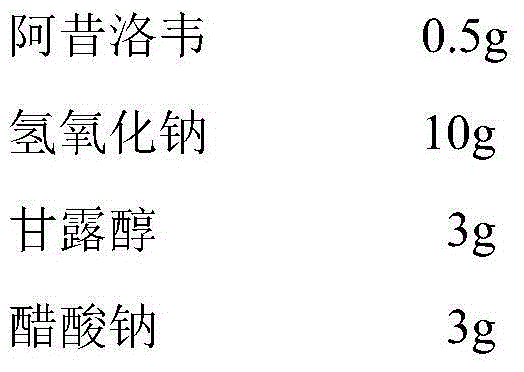

[0035] Example 1 Preparation of acyclovir freeze-dried preparation for injection

[0036]

[0037] Mix acyclovir and mannitol, add water for injection, add sodium hydroxide, stir until completely dissolved, add 1.5% ethanol by volume, and adjust the pH value to 11.0 with sodium acetate, add activated carbon for needles 0.01g / 100ml, stir , filtered and decarbonized, the medicinal solution is finely filtered with a 0.22-micron sterile microporous membrane to obtain acyclovir sterile medicinal solution, which is then subpackaged, semi-stoppered, freeze-dried, plugged, and capped to obtain freeze-dried Finished preparations.

[0038] Wherein, freeze-drying step is:

[0039] (1) Pre-freezing: Vacuumize the cabinet to 15 Pa, lower the temperature of the acyclovir sterile medicinal solution to -15 degrees Celsius under vacuum conditions, and freeze for 15 minutes; remove the vacuum, then cool down to -40 degrees Celsius, and freeze for 40 minutes. minute;

[0040](2) Sublimatio...

Embodiment 2

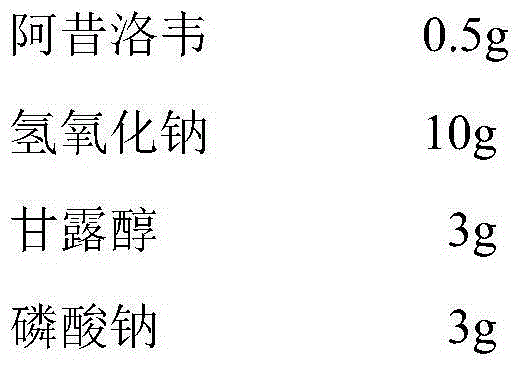

[0042] Example 2 Preparation of acyclovir freeze-dried preparation for injection

[0043]

[0044] Mix acyclovir and mannitol, add water for injection, add sodium hydroxide, stir until completely dissolved, add 2.0% ethanol by volume, and adjust the pH value to 11.2 with sodium phosphate, add 0.02g / 100ml of activated carbon for needles, and stir , filtered and decarbonized, the medicinal solution is finely filtered with a 0.22-micron sterile microporous membrane to obtain acyclovir sterile medicinal solution, which is then subpackaged, semi-stoppered, freeze-dried, plugged, and capped to obtain freeze-dried Finished preparations.

[0045] Wherein, freeze-drying step is:

[0046] (1) Pre-freezing: Vacuumize the cabinet to 10 Pa, lower the temperature of the sterile acyclovir liquid to -20 degrees Celsius under vacuum conditions, and freeze for 15 minutes; remove the vacuum, then cool down to -40 degrees Celsius, and freeze for 60 minute;

[0047] (2) Sublimation drying: v...

Embodiment 3

[0049] Example 3 Preparation of Acyclovir Lyophilized Formulation for Injection

[0050]

[0051] Mix acyclovir and mannitol, add water for injection, add sodium hydroxide, stir until completely dissolved, add 1.5% ethanol by volume, and adjust the pH value to 11.5 with sodium dihydrogen phosphate, add 0.02g / 100ml of activated carbon for needles , stirred, filtered and decarbonized, and the medicinal liquid was finely filtered with a 0.22 micron sterilizing microporous membrane to obtain acyclovir sterile medicinal liquid, which was then subpackaged, semi-stoppered, freeze-dried, plugged, and capped to obtain The finished freeze-dried preparation.

[0052] Wherein, freeze-drying step is:

[0053] (1) Pre-freezing: Vacuumize the cabinet to 15 Pa, lower the temperature of the sterile acyclovir liquid to -18 degrees Celsius under vacuum conditions, and freeze for 12 minutes; remove the vacuum, then cool down to -40 degrees Celsius, and freeze for 40 minutes. minute;

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com