Mirabegron sustained release tablet and preparation method thereof

A technology of mirabegron and sustained-release tablets, applied in the field of mirabegron sustained-release tablets and its preparation, can solve the problems of cumbersome granulation operations and the release of sustained-release components of mirabegron sustained-release tablets, etc. Achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment relates to a Mirabegron sustained-release tablet and its preparation method:

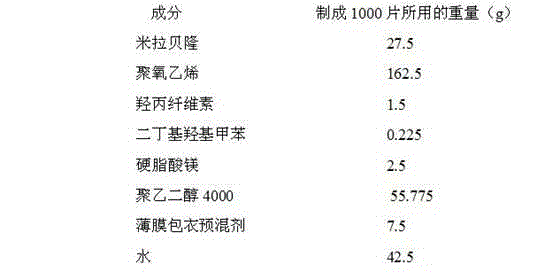

[0024] The composition ratio of Mirabegron sustained-release tablets is:

[0025]

[0026] (The composition of the film coating premix is hydroxypropyl methylcellulose, iron oxide red, and titanium dioxide; since water is removed during drying, it does not appear in the final product of the formulation)

[0027] The preparation method includes the following steps:

[0028] Step one, raw material pretreatment: take Mirabegron in a mortar and grind and smash it through a 100-mesh sieve. Dibutyl hydroxytoluene, hydroxypropyl cellulose and magnesium stearate are respectively passed through a 100-mesh sieve. The ethylene glycol is passed through a 60 mesh sieve;

[0029] Step 2: Add the pre-treated polyoxyethylene, polyethylene glycol and hydroxypropyl cellulose to the pre-treated Mirabegron according to the above-mentioned dosage ratio, and pass through a 60-mesh sieve 6 times and mix it...

Embodiment 2

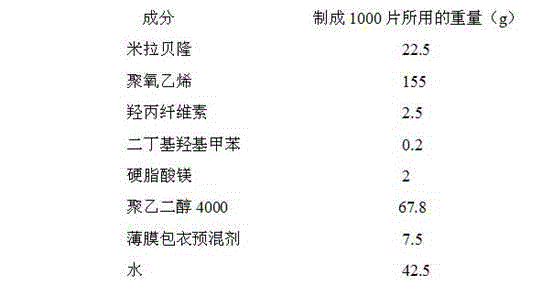

[0033] The composition ratio of Mirabegron sustained-release tablets is:

[0034]

[0035] (The composition of the film coating premix is hydroxypropyl methylcellulose, iron oxide red, and titanium dioxide; since water is removed during drying, it does not appear in the final product of the formulation)

[0036] The preparation method includes the following steps:

[0037] Step one, raw material pretreatment: take Mirabegron in a mortar and grind and smash it through a 100-mesh sieve. Dibutyl hydroxytoluene, hydroxypropyl cellulose and magnesium stearate are respectively passed through a 100-mesh sieve. The ethylene glycol is passed through a 60 mesh sieve;

[0038] Step 2: Add the pre-treated polyoxyethylene, polyethylene glycol and hydroxypropyl cellulose to the pre-treated Mirabegron according to the above-mentioned dosage ratio, and pass through a 60-mesh sieve 6 times and mix it evenly as a premix;

[0039] Step 3: Add the pre-treated dibutyl hydroxytoluene to the premix accordi...

Embodiment 3

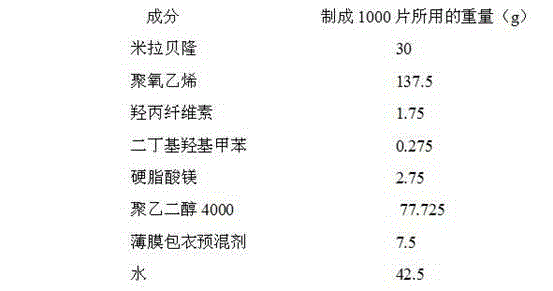

[0042] The composition ratio of Mirabegron sustained-release tablets is:

[0043]

[0044] (The composition of the film coating premix is hydroxypropyl methylcellulose, iron oxide red, and titanium dioxide; since water is removed during drying, it does not appear in the final product of the formulation)

[0045] The preparation method includes the following steps:

[0046] Step one, raw material pretreatment: take Mirabegron in a mortar and grind and smash it through a 100-mesh sieve. Dibutyl hydroxytoluene, hydroxypropyl cellulose and magnesium stearate are respectively passed through a 100-mesh sieve. The ethylene glycol is passed through a 60 mesh sieve;

[0047] Step 2: Add the pre-treated polyoxyethylene, polyethylene glycol and hydroxypropyl cellulose to the pre-treated Mirabegron according to the above-mentioned dosage ratio, and pass through a 60-mesh sieve 6 times and mix it evenly as a premix;

[0048] Step 3: Add the pre-treated dibutyl hydroxytoluene to the premix accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com