Composite antibacterial material of graphene quantum dot and fibroin, preparation and application

A graphene quantum dot and silk protein technology, which is applied to composite materials for antibacterial, based on the field of graphene quantum dots and silk protein antibacterial composite materials, can solve the problems of heavy metal pollution, poor biocompatibility and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

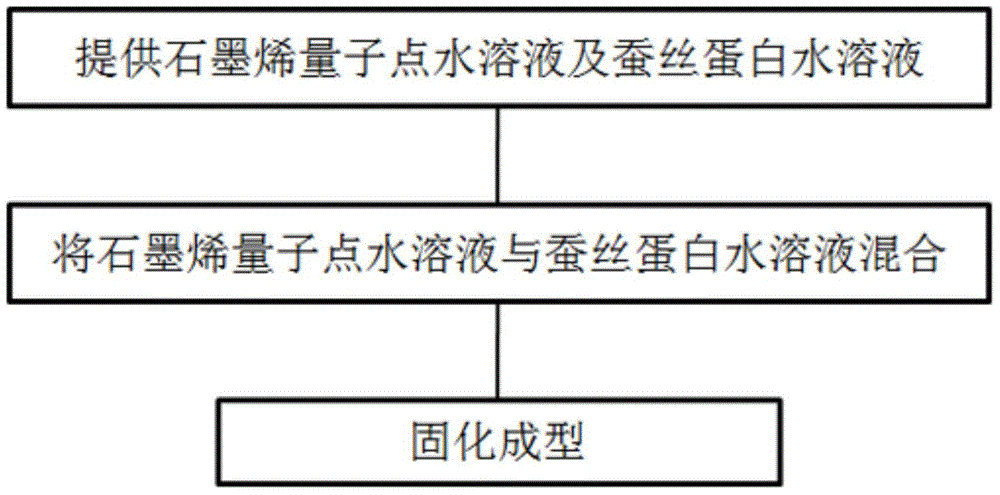

[0088] Such as figure 1 Shown, the preparation method of described graphene quantum dot and silk protein antibacterial composite material at least comprises:

[0089] First, perform step S10: provide graphene quantum dots or doped graphene quantum dot aqueous solution;

[0090] Wherein, the graphene quantum dots in this step can be directly prepared by graphene oxide, specifically, the preparation method of the graphene quantum dots includes:

[0091] Step S11: providing graphene oxide powder;

[0092] In this step, the graphene oxide powder has no specific requirements. Preferably, the graphene oxide has a lateral dimension of 0.5-100 nm.

[0093] Step S12: adding a mixed solution of nitric acid and sulfuric acid to the graphene oxide powder and stirring to form a first mixed liquid;

[0094] Wherein, the concentration of the nitric acid in the mixed solution of the nitric acid and sulfuric acid is 50-80wt%, the concentration of the sulfuric acid is 50-98wt%, and the volu...

Embodiment 1

[0171] combine figure 1 , first, perform step S10: provide graphene quantum dot powder;

[0172] Specifically, in this embodiment, in this step, graphene oxide powder is provided, including:

[0173] Step S11: providing 5.00 g of graphene oxide powder;

[0174] Step S12: Add the graphene oxide powder into a mixture of 50 mL of concentrated nitric acid (67 wt%) and 120 mL of concentrated sulfuric acid (98 wt%), stir mechanically at 5°C for 60 min at a stirring rate of 1200 r / min, and form the first mixed liquid;

[0175] Step S13: Slowly add 60g of NaClO to the first mixed liquid 3 In order to generate an oxidation reaction, control the reaction temperature of the oxidation reaction to 0-5°C, and react for 12 hours to form a second mixed liquid;

[0176] Step S14: Cool the second mixed liquid to room temperature, add 200 mL of distilled water to dilute to form a third mixed liquid, and filter it with a 10 nm porous alumina filter;

[0177] Step S15: adding ammonia water to...

Embodiment 2

[0186] Select the graphene quantum dot powder obtained in step S16 in Example 1, carry out step S17, disperse the graphene quantum dots in the solvent, add B-containing dopant, solvothermal reaction, prepare B-doped graphene quantum dots .

[0187] Specifically, in this embodiment, take 0.5 g of the graphene quantum dot powder obtained in step S16, and ultrasonically disperse it in 10 mL of water, add 1.0 mL of dimethylaminoborane as a dopant to the dispersion, and place the mixed liquid in Lining a polytetrafluoroethylene reactor with a volume of 20mL, and placing the inner lining in a stainless steel reactor body, heating and reacting at 200°C for 24h.

[0188] Afterwards, step S18 is performed, and after the reaction, the reaction solution is filtered, dialyzed, and freeze-dried to obtain B-doped graphene quantum dot powder.

[0189] Specifically, in this example, the reaction liquid obtained in step S17 was cooled to room temperature, and filtered with a 10 nm porous alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com