Bamboo carbon fiber gypsum board and preparation method thereof

A bamboo charcoal fiber and gypsum board technology, which is applied in the field of building materials, can solve the problems of affecting the appearance of gypsum board, affecting the air purification performance of bamboo charcoal, adsorption performance and anion release ability, and not having enhanced practical strength, etc., to achieve strong adsorption capacity and strength Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

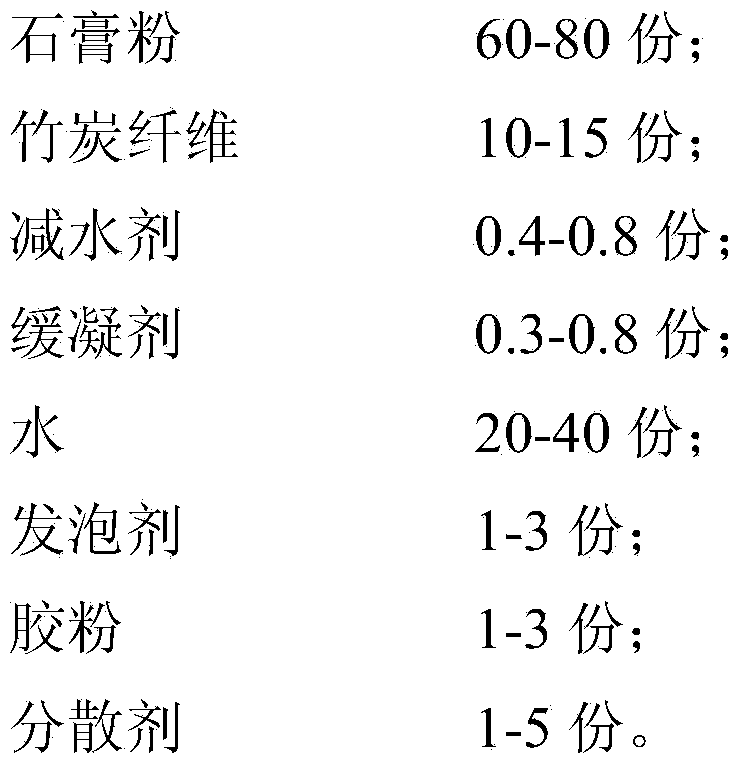

[0035] Each raw material component of embodiment 1-6 carries out proportioning by weight in table 1:

[0036] Table 1

[0037]

[0038] In an embodiment, the foaming agent is composed of 1% sodium lauryl sulfate, 0.25% FM-550 foam stabilizer and 98.75% water by mass fraction.

[0039] The rubber powder is composed of NSJF-5 gypsum bonding rubber powder, hemihydrate gypsum powder and heavy calcium powder with a weight ratio of 1.2:80:20.

[0040] Add raw materials other than bamboo charcoal fiber into a stirring device and stir evenly to obtain gypsum slurry, then put the obtained gypsum slurry into a mixing bucket, and then take the diameter of 10-20 μm according to the parts by weight in Table 1, and the length of 5- The 20mm bamboo charcoal fiber is sprayed into the mixing tank by a spraying device, and at the same time, the gypsum slurry in the mixing tank is stirred to make the bamboo charcoal fiber evenly distributed, thereby preparing the pouring slurry.

[0041] Pu...

Embodiment 7-11

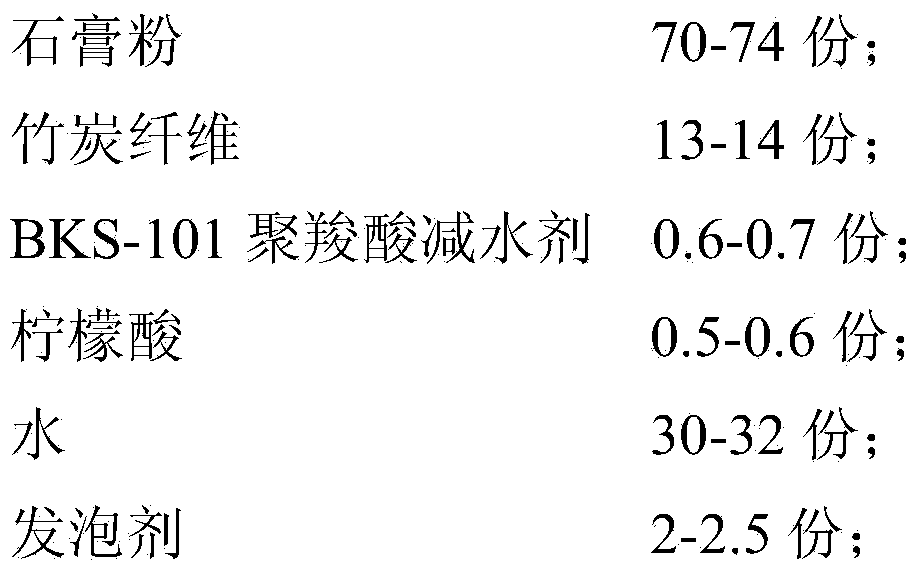

[0050] According to the proportioning by weight of each raw material component in Table 3, the bamboo charcoal fiber gypsum board was prepared according to the technique of Example 1.

[0051] table 3

[0052]

[0053] Table 4 characterizes the results of Examples 3, 7-11 from the flexural strength of bamboo charcoal fiber gypsum board of the present invention, compressive strength, free formaldehyde removal rate, ammonia removal rate, release of negative ions and far-infrared radiation rate above 6 indicators . It can be clearly seen that the specific combination of BKS-101 polycarboxylate superplasticizer, citric acid and silicon carbide powder is used in Example 3, and the performance of the gypsum board produced is optimal.

[0054] It can be seen from Example 3, Example 7, Example 10, and Example 11 that when the water reducer is ASD-2 aliphatic high-efficiency water reducer, silicon carbide powder or fly ash is used as the dispersant for gypsum board The 6 indicator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com