Preparation method for natural high-antibacterial-property water-absorbent resin

A water-absorbent resin and antibacterial technology, applied in the field of functional polymer materials, can solve the problems affecting the balance of SAP performance, adverse effects of SAP application performance, inability to effectively inhibit bacterial growth, etc., achieving low cost, excellent water absorption and water retention performance, The effect of excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

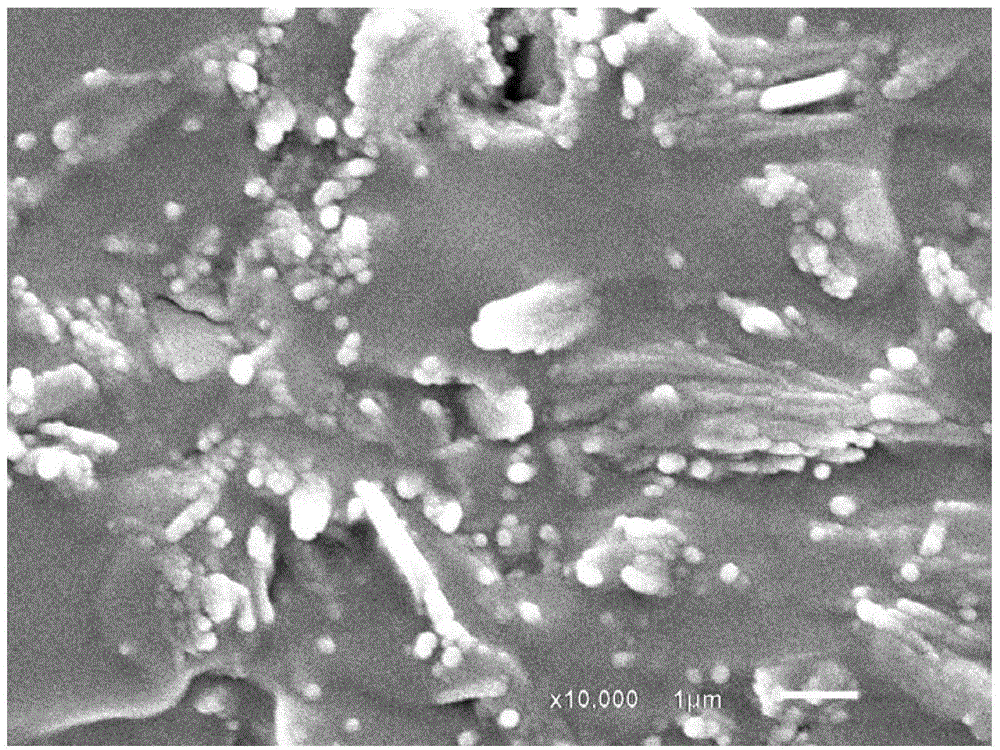

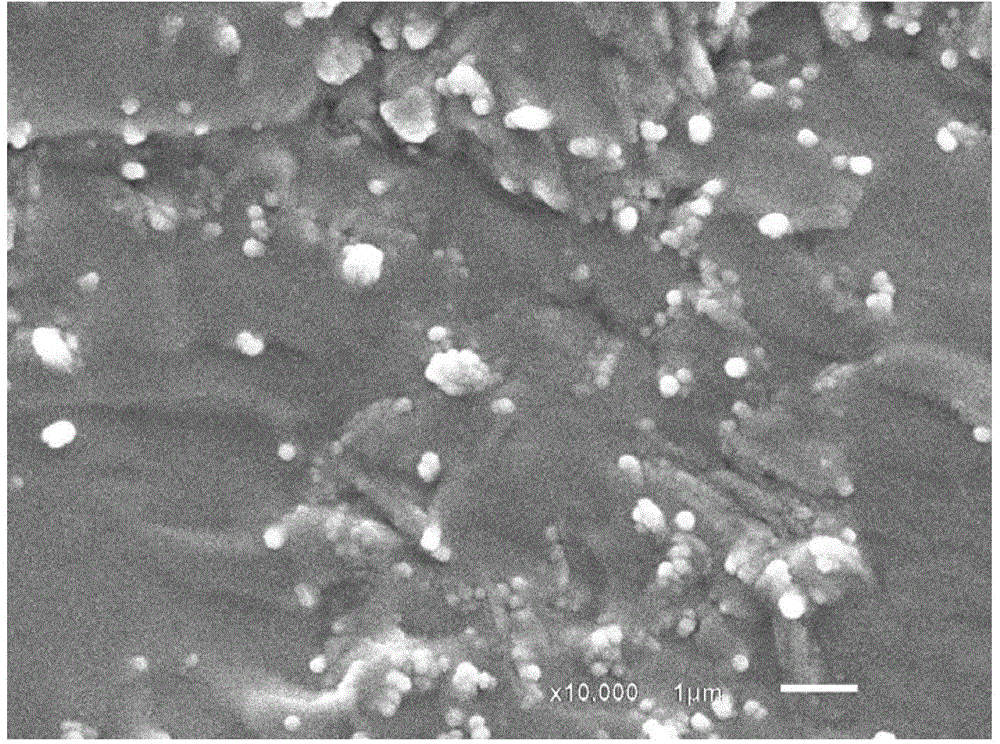

Image

Examples

Embodiment 1

[0026] 1) Weigh 50 g of acrylic acid in a three-necked flask, and prepare a 60% acrylate solution with a 25% NaOH solution under an ice-water bath;

[0027] 2) Then add 10g of acrylamide to the acrylate solution, and add 40g of deionized water; then add 10g of molecular weight M w =3000g / mol, the mass fraction is 30% chitosan aqueous solution; add 1% N,N,-methylenebisacrylamide as a crosslinking agent to obtain the early stage solution;

[0028] 3) At room temperature, add 2% of the oxidizing component and 0.5% of the reducing component in the mass fraction of the previous solution into a three-necked flask, stir evenly, and then react at a temperature of T=70°C, and wait until the system condenses After gluing, continue to keep warm for 1 hour under the condition of temperature T=70°C; discharge, wash with water, soak in ethanol, rinse, cut into pieces, dry, and pulverize to obtain the natural high antibacterial water-absorbing resin of the present invention.

Embodiment 2

[0030] 1) Weigh 50g of acrylic acid in a three-necked flask, under an ice-water bath, use a 25% NaOH solution to prepare a 70% acrylate solution,

[0031] 2) Then add 15g of acrylamide to the acrylate solution, and add 50g of deionized water; then add 15g of molecular weight M w =5000g / mol, the mass fraction is 20% chitosan aqueous solution; add 1.5% N,N,-methylenebisacrylamide as a crosslinking agent, stir evenly, and obtain the early stage solution;

[0032] 3) At room temperature, add 2% of the oxidizing component and 0.5% of the reducing component in the mass fraction of the previous solution into a three-necked flask, stir evenly, and then react at a temperature of T=70°C, and wait until the system condenses After gluing, continue to keep warm for 1 hour under the condition of temperature T=70°C; discharge, wash with water, soak in ethanol, rinse, cut into pieces, dry, and pulverize to obtain the natural high antibacterial water-absorbing resin of the present invention. ...

Embodiment 3

[0034] 1) Weigh 50g of acrylic acid in a three-necked flask, under an ice-water bath, use a 25% NaOH solution to prepare a 60% acrylate solution,

[0035] 2) Then add 10g of acrylamide to the acrylate solution, and add 60g of deionized water; then add 30g of molecular weight M w =10000g / mol, the mass fraction is 10% chitosan aqueous solution; add 1.5% N,N,-methylenebisacrylamide as a cross-linking agent, stir evenly to obtain the early stage solution;

[0036] 3) At room temperature, add 2.5% of the oxidizing component and 1% of the reducing component to the three-necked flask respectively by mass fraction of the previous solution, stir evenly, and then react at a temperature of T=90° C. After gluing, continue to keep warm for 1 hour under the condition of temperature T=90°C; discharge, wash with water, soak in ethanol, rinse, cut into pieces, dry, and crush to obtain the natural high antibacterial water-absorbing resin of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com