Polyester resin for weather-proof and impact-resisting powder coating and preparation method of polyester resin

A technology of powder coating and polyester resin, which is applied in the field of polyester resin, can solve the problems such as the impact of polyester resin on impact performance, and achieve the effects of good storage stability, excellent weather resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

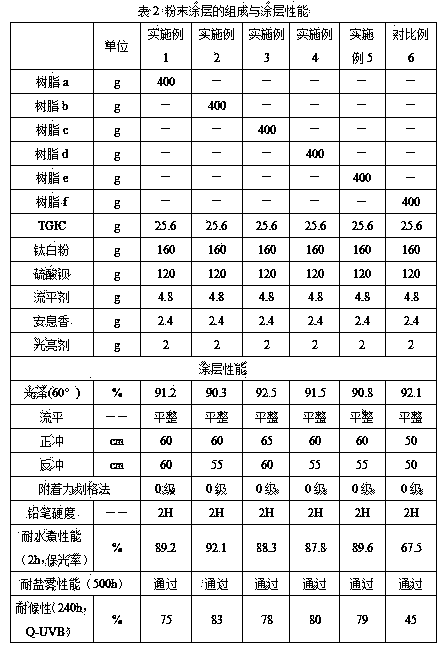

Examples

Embodiment Construction

[0028] (1) Add neopentyl glycol, terephthalic acid, isophthalic acid, trimethylolpropane and monobutylene in the proportioning amount in Table 1 in the 100L reactor equipped with distillation column, agitator, and heating device Based on tin oxide, heat until the material melts, start stirring with nitrogen, the stirring rate is 30-50r / min, continue to heat up the reaction, at about 180°C, esterification water begins to be formed and distilled, and then the temperature rises at 10-20°C / h Gradually raise the temperature to 240-250°C, keep it warm for 3-5 hours, and measure the acid value when the column top temperature drops to about 40°C and the material is clear. The acid value range is 12-15mgKOH / g.

[0029] (2) Take isophthalic acid, an acidolysis agent, and add it to the above-mentioned reaction kettle, and continue the heat preservation reaction at 240°C for 3-5 hours. 35mgKOH / g, the reaction can be stopped when the viscosity reaches 5000-6000mPa?s, and the vacuum is rele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com