A kind of preparation method of polymer fluid loss reducer for oil-based drilling fluid

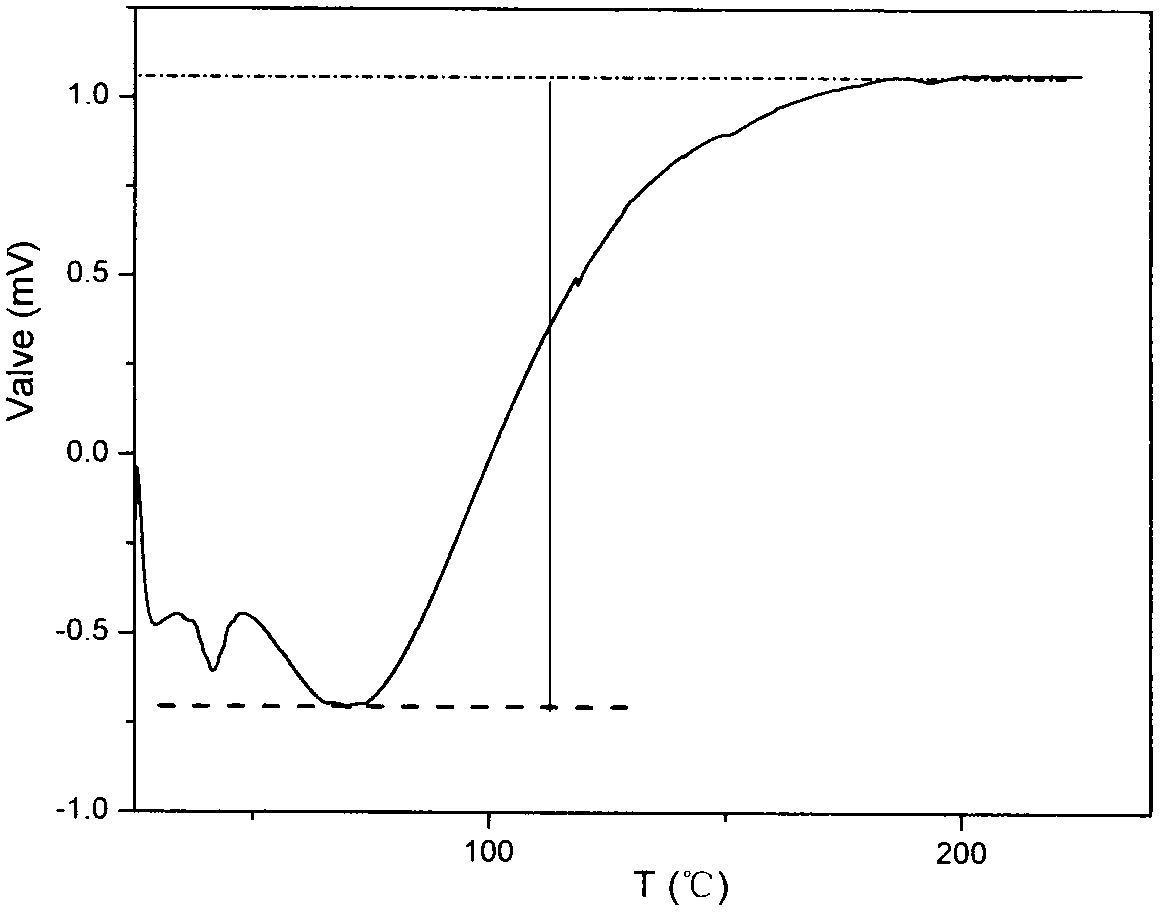

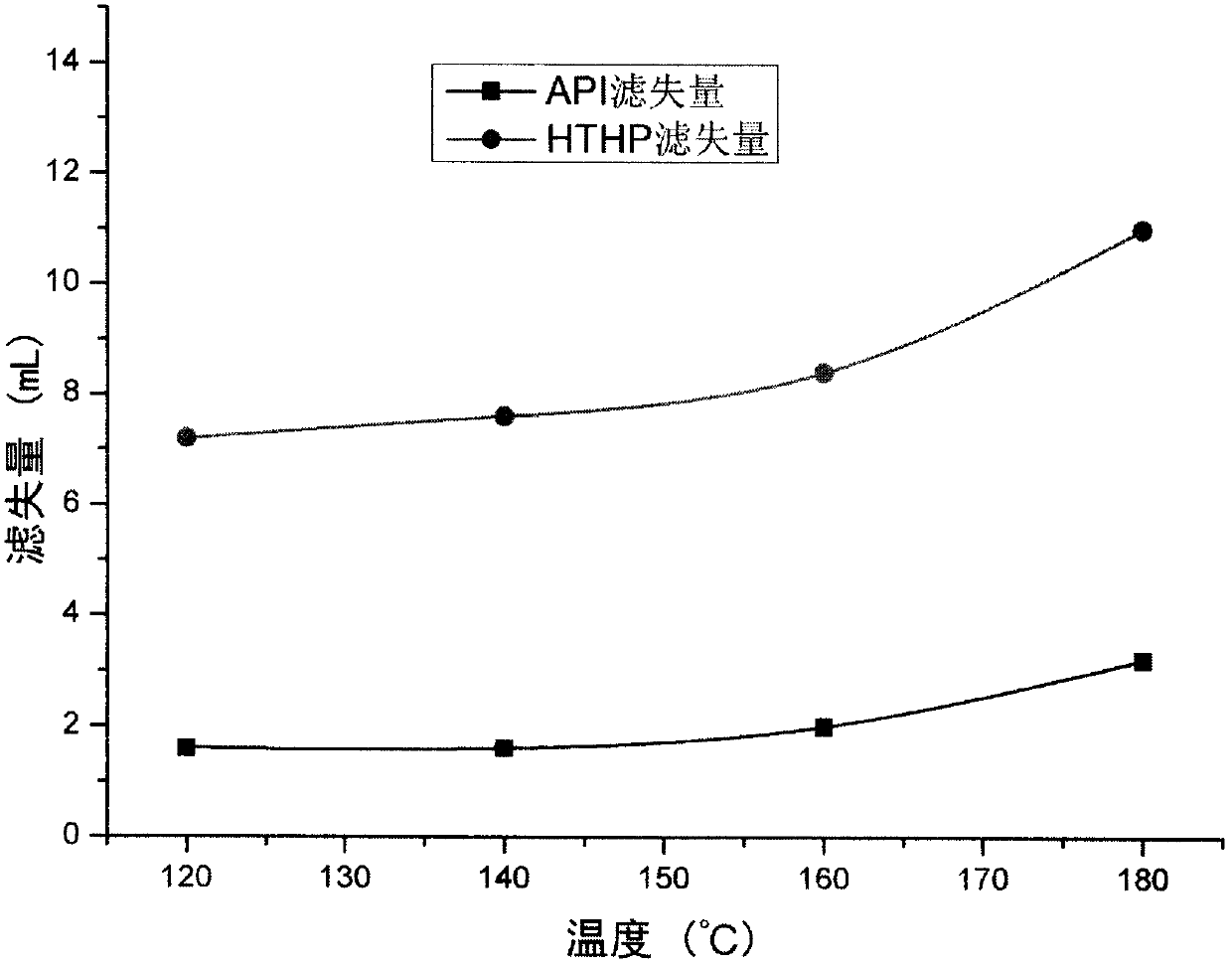

A technology of oil-based drilling fluid and fluid loss reducer, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems affecting the rheological properties of the system, such as adding dosage, and achieve the improvement of comprehensive performance, simple method and vitrification Moderate transition temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of a polymer fluid loss reducer for oil-based drilling fluid, the method comprising the steps of:

[0021] (1) Add methanol and deionized water into a three-necked flask and stir for 20 minutes to make them evenly mixed;

[0022] (2) Add the dispersant polyvinylpyrrolidone to the step (1) and feed nitrogen gas at the same time, and magnetically stir it at room temperature to dissolve it, and the rotation speed is 1000-2000rpm;

[0023] (3) Add acrylamide and octadecyl methacrylate to step (2) respectively, stir well and then add the initiator azobisisobutyronitrile, place it in a water bath and evenly heat it up to 70°C and start the timing reaction 5h, while adding crosslinking agent divinylbenzene in different reaction time periods;

[0024] (4) Cool to room temperature after the reaction, centrifuge the reaction crude product and wash it with absolute ethanol for 3-5 times to remove unreacted monomers, and finally place it in a vacuum drying ove...

Embodiment 2

[0026] According to the preparation method of the polymer fluid loss control agent for oil-based drilling fluid described in Example 1, the volume ratio of methanol to deionized water in the step (1) is 7:3.

Embodiment 4

[0028] According to the preparation method of the polymer fluid loss control agent for oil-based drilling fluid described in embodiment 1 or 2, the amount of dispersant polyvinylpyrrolidone added in the step (2) is 4% of the total volume of the solution.

[0029] Example 4:

[0030] According to the preparation method of polymer fluid loss control agent for oil-based drilling fluid described in embodiment 1 or 2 or 3, the mass ratio of acrylamide and stearyl methacrylate in the described step (3) is 1:3 , the dosage of the initiator is 1% of the total volume, and the dosage of the crosslinking agent is 2% of the total volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com