Combined process for conversion of C10+ heavy aromatics to light aromatics

A technology for lightening heavy aromatics and a combined process, which is applied in the field of oil refining, can solve the problems of difficult ring opening of polycyclic aromatics, low reaction conversion rate, and no competitive advantage, etc., and achieves strong lightening ability, high conversion rate, and reduced Effect of Hydrogenation Saturation Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

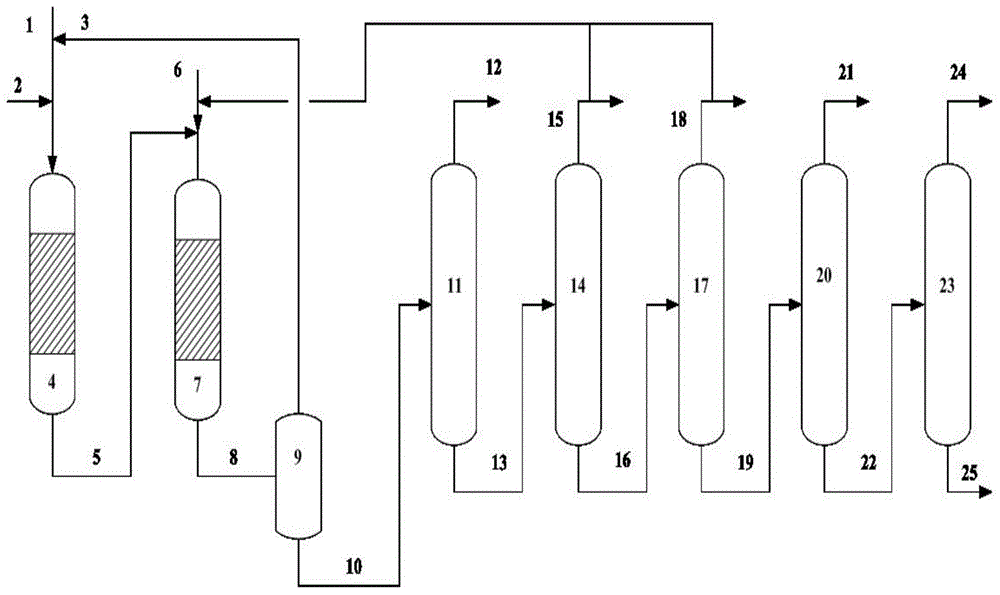

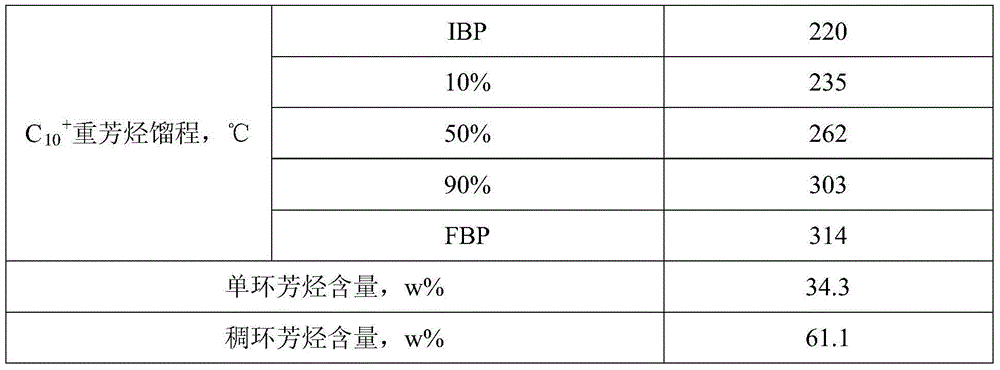

[0030] C using a fixed bed reactor 10 + Investigation of combined process of selective hydrogenation and transalkylation of heavy aromatics. Among them, the selective hydrogenation catalyst for fused ring aromatics (noble metal Pt content 0.1%) was prepared according to the method in patent CN103551180A, and the heavy aromatics transalkylation catalyst and non-aromatic cracking catalyst were self-made in the laboratory. The feed to the reactor is from the top to the bottom, and the composition of the liquid product is analyzed by gas chromatography and chromatography-mass spectrometry.

[0031] C 10 + Heavy aromatics conversion, mixed xylene selectivity, C 9 Aromatic selectivity is defined as:

[0032] C 10 + Conversion of heavy aromatics = (C in the feed 10 + Mass of heavy aromatics - C in the product 10 + Heavy aromatics mass) / C in the feed 10 + Mass of heavy aromatics × 100%

[0033] Mixed xylene selectivity=the quality of mixed xylene in the product / (total ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com