Metal surface cleaning agent and preparation method thereof

A metal surface and cleaning agent technology, applied in the field of chemical cleaning agents, can solve problems such as difficult cleaning, operator injury, and environmental pollution, and achieve the effects of improving the ability to remove oil stains, enhancing friction, and improving antirust capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

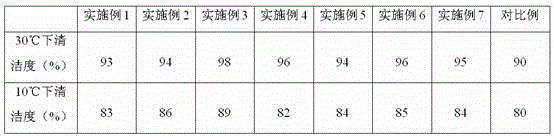

Examples

Embodiment 1

[0028] A metal surface cleaning agent, comprising the following raw materials in parts by weight: 12 parts of alkylphenol polyvinyl ether, 1 part of defoamer, 0.5 part of alcohol ether, 4 parts of hydrogen peroxide, 8 parts of ethylenediaminetetraacetic acid salt , 3 parts of 800 mesh pearl powder, 4 parts of sodium hydroxide, 20 parts of deionized water.

[0029] The preparation method of above-mentioned metal surface cleaning agent, comprises the following steps:

[0030] Step 1, weighing alkylphenol polyvinyl ether, defoamer, alcohol ether, hydrogen peroxide, edetate, pearl powder, sodium hydroxide, deionized water;

[0031] Step 2, after mixing alkylphenol polyvinyl ether, alcohol ether, ethylenediamine tetraacetate, sodium hydroxide and deionized water, stirring and heating at 500rpm for 2 minutes, cooling naturally to obtain the mixed solution I, wherein heating The temperature is 50°C;

[0032] Step 3, adding pearl powder to the mixed solution I, and stirring at 2000r...

Embodiment 2

[0036] A metal surface cleaning agent, comprising the following raw materials in parts by weight: 15 parts of alkylphenol polyvinyl ether, 2 parts of defoamer, 0.6 part of alcohol ether, 5 parts of hydrogen peroxide, 10 parts of ethylenediamine tetraacetate , 6 parts of 800 mesh pearl powder, 6 parts of sodium hydroxide, 28 parts of deionized water.

[0037] The preparation method of above-mentioned metal surface cleaning agent, comprises the following steps:

[0038] Step 1, weighing alkylphenol polyvinyl ether, defoamer, alcohol ether, hydrogen peroxide, edetate, pearl powder, sodium hydroxide, deionized water;

[0039] Step 2, after mixing alkylphenol polyvinyl ether, alcohol ether, ethylenediamine tetraacetate, sodium hydroxide and deionized water, stirring and heating at 600rpm for 4 minutes, cooling naturally to obtain the mixed solution I, wherein heating The temperature is 50°C;

[0040] Step 3, adding pearl powder to the mixed solution I, and stirring at 3000rpm for...

Embodiment 3

[0044] A metal surface cleaning agent, comprising the following raw materials in parts by weight: 16 parts of alkylphenol polyvinyl ether, 4 parts of defoamer, 0.7 parts of alcohol ether, 7 parts of hydrogen peroxide, 13 parts of ethylenediamine tetraacetate , 8 parts of 800 mesh pearl powder, 7 parts of sodium hydroxide, 30 parts of deionized water, 1 part of sodium molybdate.

[0045] The preparation method of above-mentioned metal surface cleaning agent, comprises the following steps:

[0046] Step 1, weighing alkylphenol polyvinyl ether, defoamer, alcohol ether, hydrogen peroxide, edetate, pearl powder, sodium hydroxide, deionized water;

[0047] Step 2, after mixing alkylphenol polyvinyl ether, alcohol ether, ethylenediamine tetraacetate, sodium hydroxide and deionized water, stirring at 700rpm and heating for 5 minutes, cooling naturally to obtain the mixed solution I, wherein heating The temperature is 65°C;

[0048] Step 3, adding pearl powder to the mixed solution I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com