Method for improving heavy haul railway subgrade by use of fiber-reinforced stabilized soil

A technology of railway roadbed and fiber reinforcement, applied in chemical instruments and methods, roads, roads, etc., can solve the problems of easy cracking, low strength of solidified soil, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for improving heavy-duty railway roadbed with fiber-reinforced solidified soil is as follows: mixing monofilament bundle-shaped fibers and soil curing agent into the heavy-duty railway roadbed soil, wherein the content of the monofilament bundle-shaped fiber is 0.05 -0.5% dry soil weight, fiber length 3-54mm; the content of soil solidification agent is 3-7% dry soil weight, and the formula of soil solidification agent is as follows by weight: aluminosilicate 30-42%, iron aluminate 18-24%, sulfate 10-16%, sulfite 10-16%, sulfoaluminate 16-20%, chloride 4-8%, and oxide 3-6%.

[0035] The aluminosilicate is a mixture of sodium aluminosilicate and calcium aluminosilicate, with a weight ratio of 3:4;

[0036] Said iron aluminate is a mixture of calcium iron aluminate and tetracalcium iron aluminate, with a weight ratio of 4:3;

[0037] The sulfate is a mixture of sodium sulfate, calcium sulfate and aluminum sulfate, and the weight ratio is 3:3:5;

[0038] The sulfite is a ...

Embodiment 2

[0048] The embodiment of the present invention is: firstly mix the soil solidifying agent and the roadbed soil uniformly to form solidified soil, and then mix the fibers into the solidified soil to approximately form a three-dimensional fiber reinforced solidified soil. Since the degree of cementation between the soil curing agent and the subgrade soil or the degree of mineral reaction hydration and crystallization is related to time, the structural strength, crack resistance, vibration resistance, impermeability and stability of the fiber-solidified soil are maintained. Age, but the curing time and curing conditions are the same as those of solidified soil.

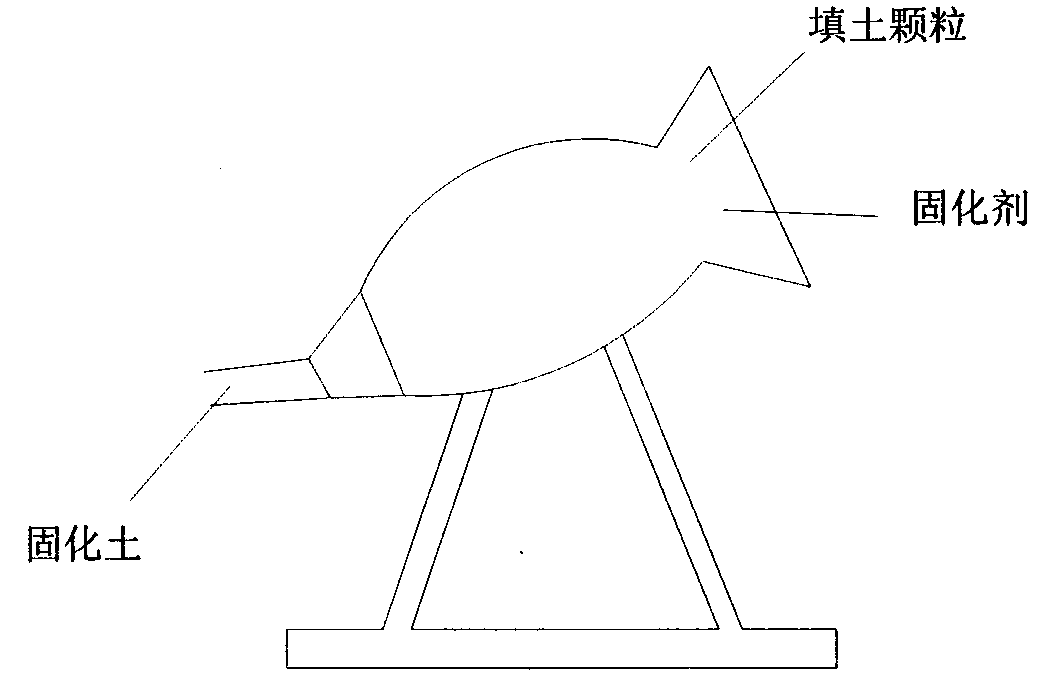

[0049] The reinforcement mechanism of fiber-solidified soil includes two parts: (1) The reinforcement mechanism of soil solidification agent on subgrade soil. One is that the soil curing agent reacts and solidifies with the active ingredients in the subgrade soil. The soil curing agent chemically reacts with the minerals i...

Embodiment 3

[0052] (1) Fiber selection

[0053] There are many types of fibers used to reinforce solidified soils. Considering the engineering practice, the following requirements shall be met: (1) Chemical characteristics requirements. The fiber is required to have acid and alkali corrosion resistance and anti-aging characteristics, and has good chemical stability, which can ensure that the fiber can perform long-term effects in the cured body and maintain the excellent performance of the cured body. (2) Physical mechanics requirements. The fiber has good dispersibility, good grip strength and compatibility, high strength, especially excellent tensile properties.

[0054] (2) Construction technology

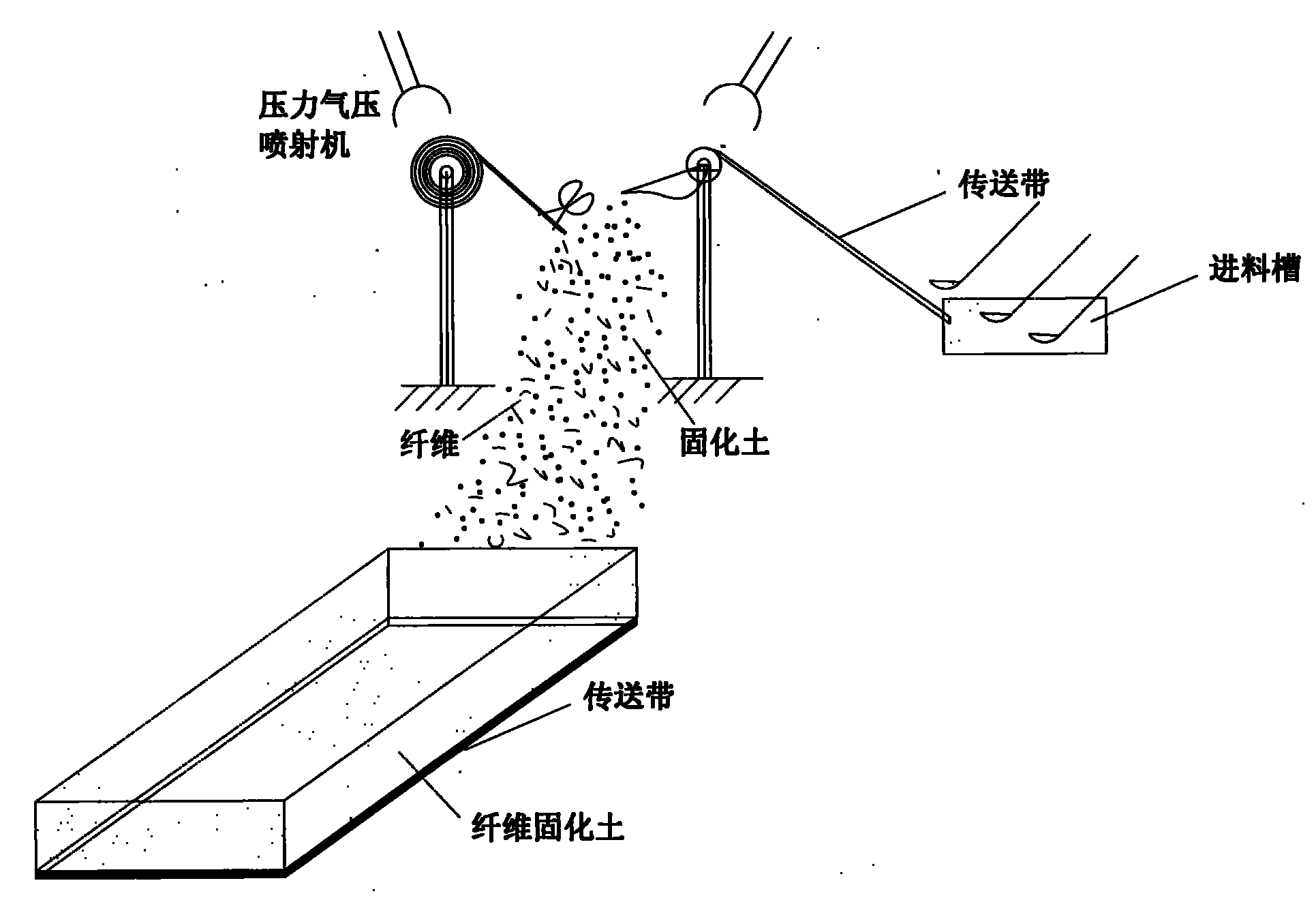

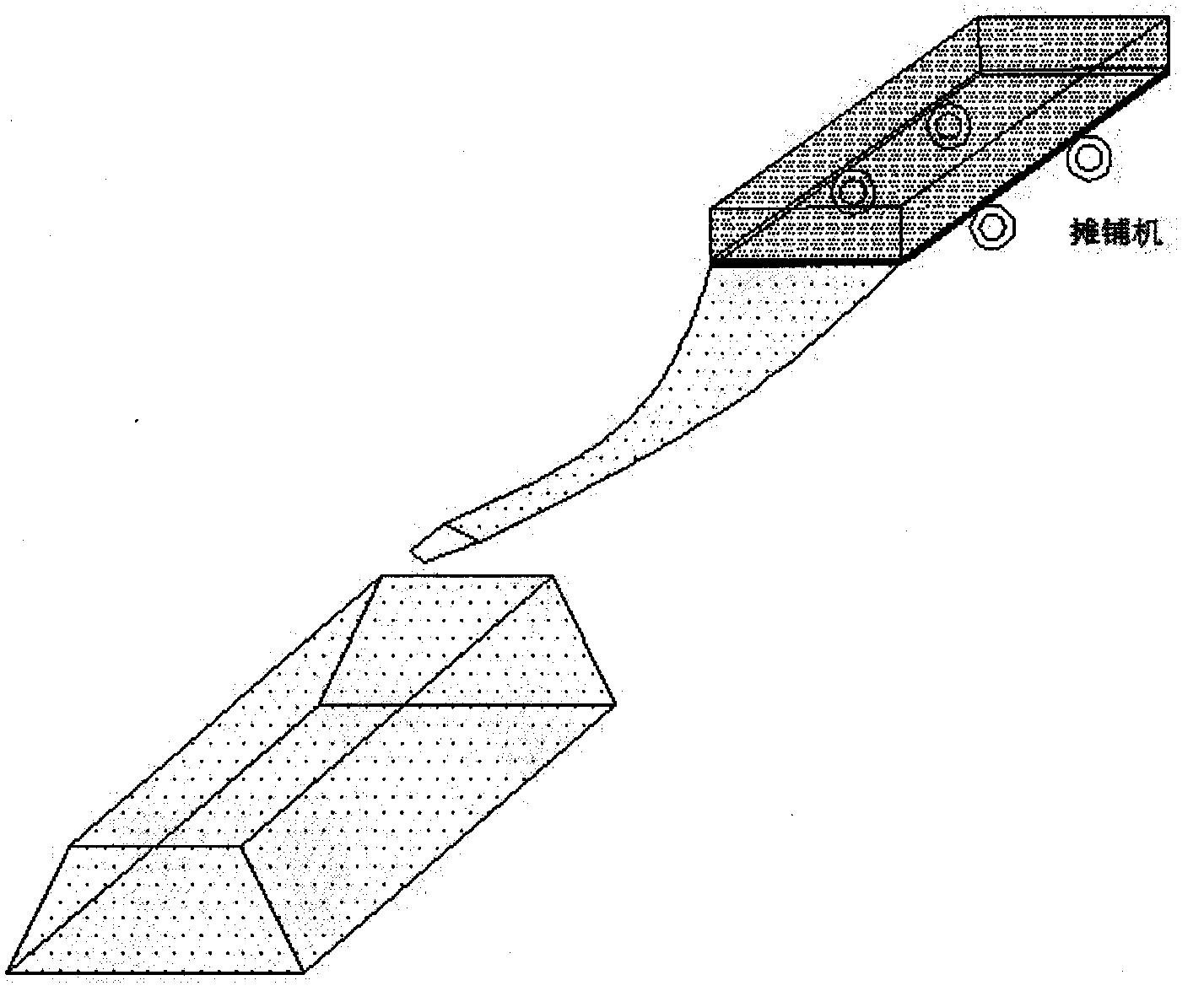

[0055] In the construction process of the present invention, the most critical construction process is the uniformity of the mixing of fibers and solidified soil. According to the demand for fiber-solidified soil according to the scale of construction, the mixing process is divided into: spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com