Rechargeable aqueous ion battery

An ion battery and water system technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as oxygen sensitivity, difficulty in ensuring long-term cycle, and cycle performance that cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

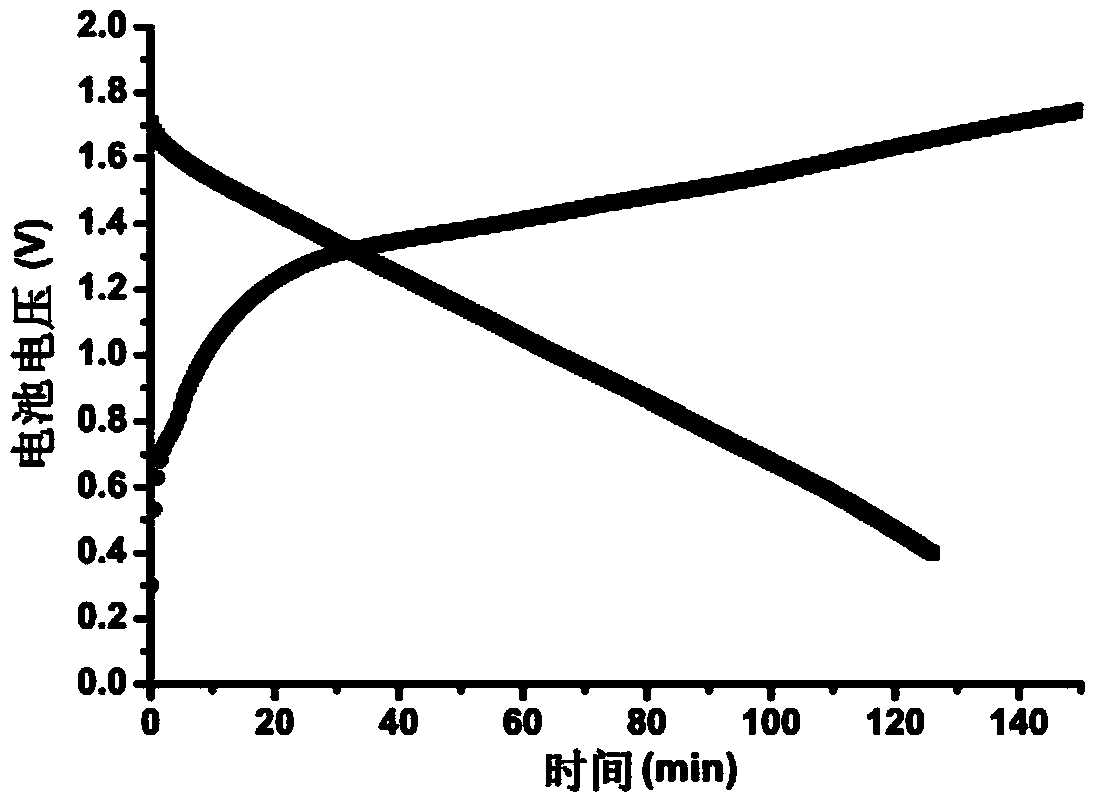

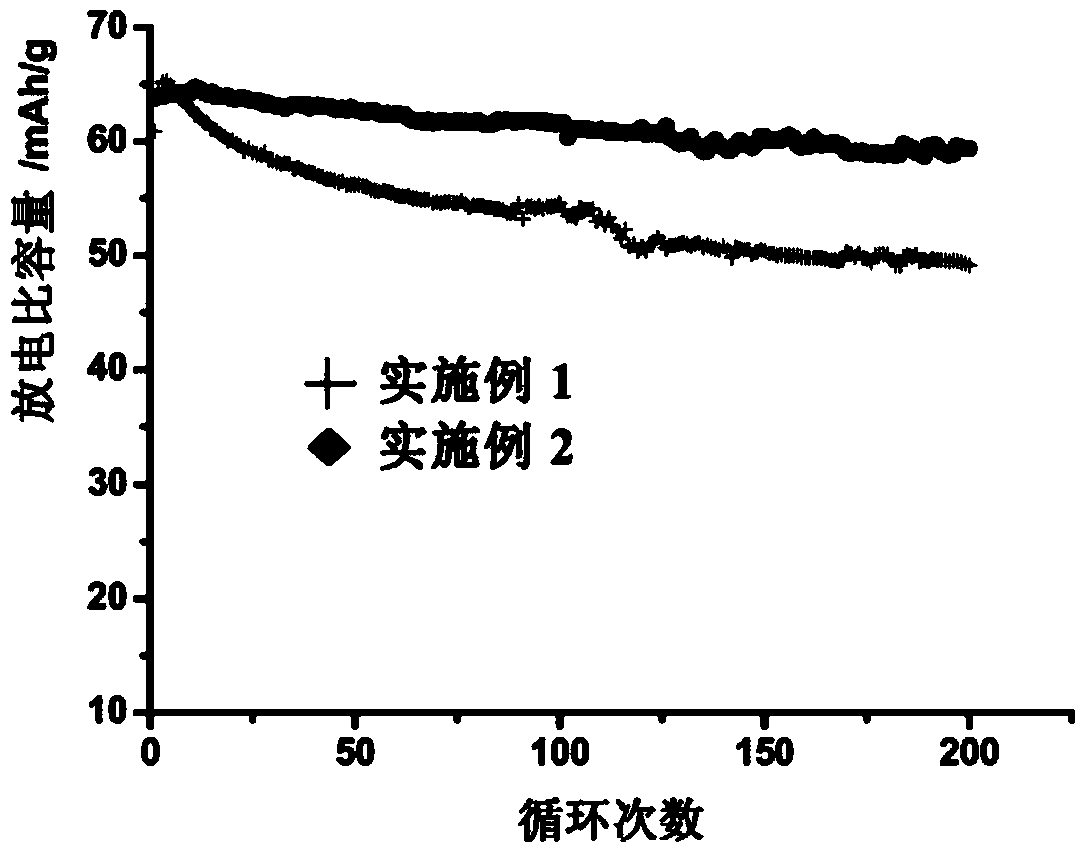

Embodiment 1

[0028] The positive electrode active material uses commercial LiMn 2 o 4 . Cathode material according to LiMn 2 o 4 : Acetylene black: PTFE binder = 80:10:10 mass ratio and mix evenly, after drying, roll or roll the mixture onto a stainless steel mesh, and then make an electrode sheet with a thickness of 0.2mm. The negative electrode material is commercialized activated carbon, which is uniformly mixed according to the mass ratio of activated carbon: conductive carbon black: PTFE binder = 80:10:10. After drying, the mixture is rolled or rolled onto a stainless steel mesh, and then made into a 1mm thick electrode pads. Using analytically pure raw materials, configure 1M Li 2 SO 4 Electrolyte, adjust the pH of the electrolyte to 7.50 with LiOH. The positive and negative electrodes are cut according to the specifications, and the hydrophilic treated PP-based separator and the above-mentioned electrolyte are used to pair and assemble into a battery. In the working voltage ...

Embodiment 2

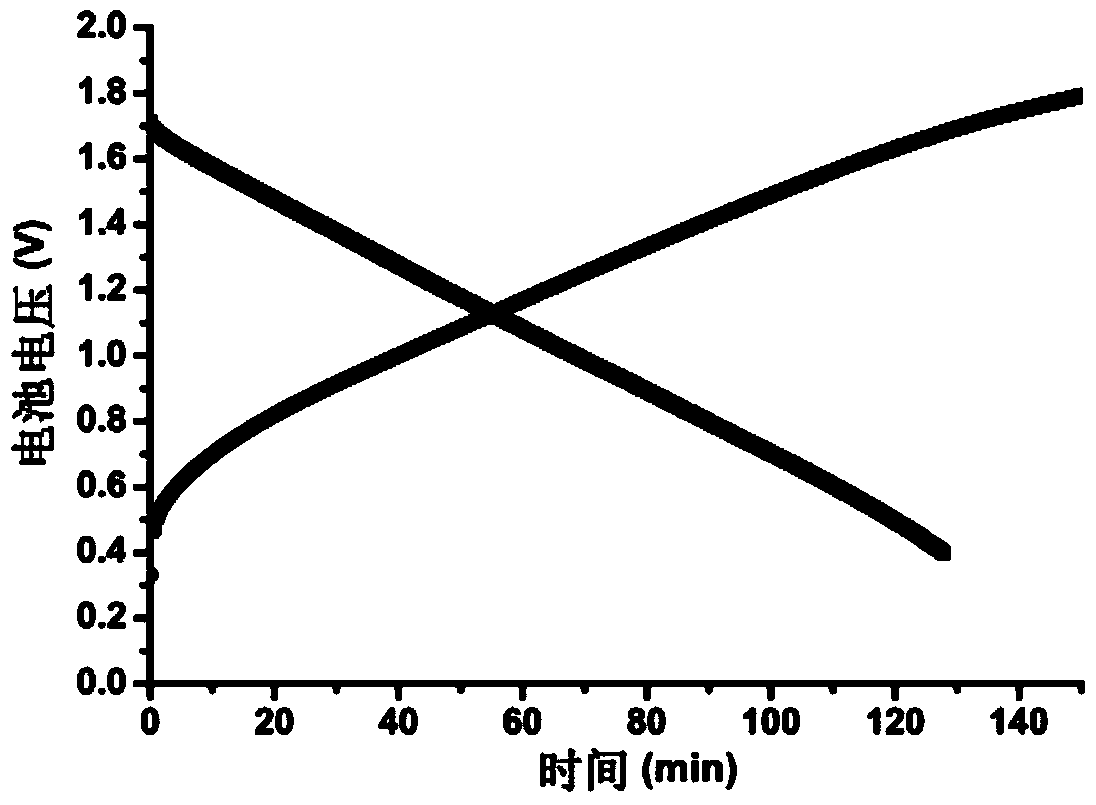

[0030] The positive electrode active material uses commercial LiMn 2 o 4 . Cathode material according to LiMn 2 o 4 : Acetylene black: PTFE binder = 80:10:10 mass ratio and mix evenly, after drying, roll or roll the mixture onto a stainless steel mesh, and then make an electrode sheet with a thickness of 0.2mm. The negative electrode material is commercialized activated carbon, which is uniformly mixed according to the mass ratio of activated carbon: conductive carbon black: PTFE binder = 80:10:10. After drying, the mixture is rolled or rolled onto a stainless steel mesh, and then made into a 1mm thick electrode pads. Using analytically pure raw materials, configure 1M Li 2 SO 4 Electrolyte, containing 0.4 M lithium acetate solution in the electrolyte, and adjusting the pH value of the electrolyte to 7.50 with LiOH. The positive and negative electrodes are cut according to the specifications, and the hydrophilic treated PP-based separator and the above-mentioned electro...

Embodiment 3

[0032] The positive electrode active material uses commercial LiMn 2 o 4 . Cathode material according to LiMn 2 o 4 : Acetylene black: PTFE binder = 80:10:10 mass ratio and mix evenly, after drying, roll or roll the mixture onto a stainless steel mesh, and then make an electrode sheet with a thickness of 0.2mm. The negative electrode material is commercialized activated carbon, which is uniformly mixed according to the mass ratio of activated carbon: conductive carbon black: PTFE binder = 80:10:10. After drying, the mixture is rolled or rolled onto a stainless steel mesh, and then made into a 1mm thick electrode pads. Using analytically pure raw materials, configure 1M Na 2 SO 4 Electrolyte, adjust the pH value of the electrolyte to 7.50 with NaOH. The positive and negative electrodes are cut according to the specifications, and the hydrophilic treated PP-based separator and the above-mentioned electrolyte are used to pair and assemble into a battery. In the working vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com