Preparation method of amino-modified Pd/TiO2 photocatalyst

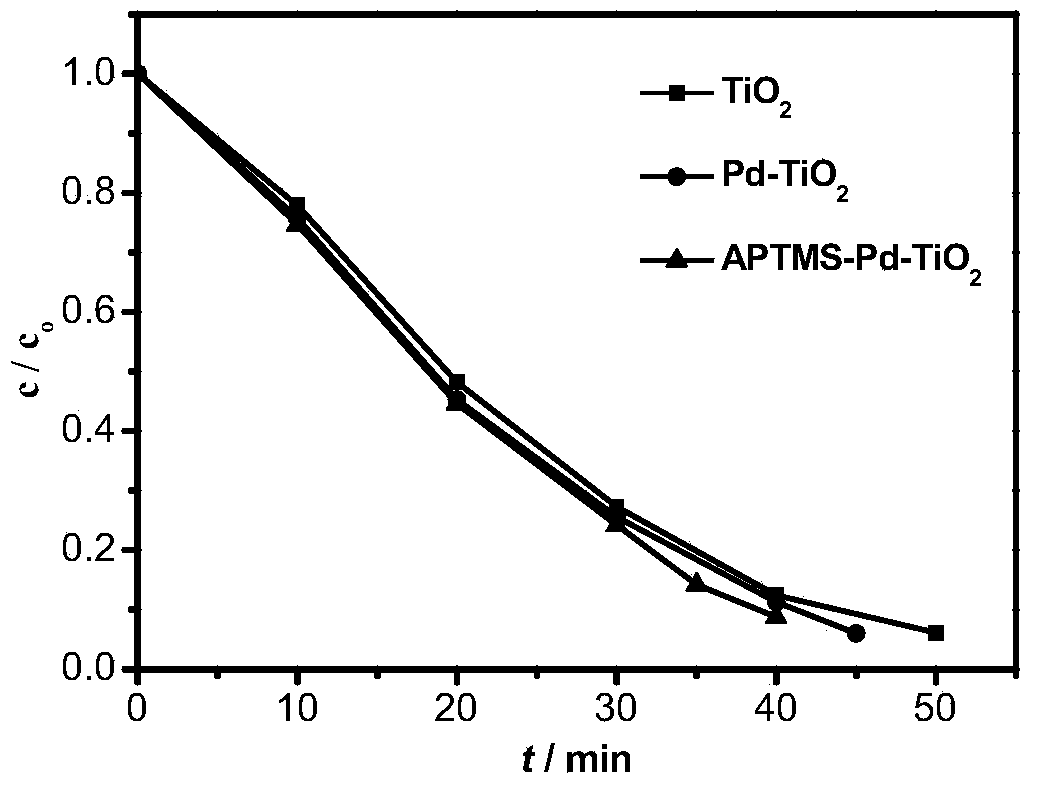

A technology of photocatalyst and amino modification, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low degradation efficiency, achieve improved dispersion, Improve the effect of degradation and improve the photon quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of Pd / TiO with amino modification 2 The preparation method of photocatalyst specifically comprises the steps:

[0021] (1) Synthesis of TiO with {001} high-energy crystal plane 2 Nanosheets

[0022]Put 10ml of tetrabutyl titanate and 0.8ml of hydrofluoric acid aqueous solution with a concentration of 47% by volume in a polytetrafluoroethylene-lined autoclave, and conduct a hydrothermal reaction at 180°C for 24 hours. , 0.1M NaOH and deionized water for 3 times each, then placed in a vacuum drying oven at a controlled temperature of 80°C for 12 hours, then removed and ground, then placed in a muffle furnace for calcination at a controlled temperature of 400°C for 2 hours, and finally passed 200 mesh sieve, that is to get TiO with {001} high-energy crystal plane 2 Nanosheets;

[0023] (2) APTMS modified TiO with {001} high-energy crystal plane 2 Nanosheets

[0024] Add 0.05ml-2ml of APTMS to 100ml of water, then add 150mg of TiO with {001} high-energy crystal...

Embodiment 2

[0035] A kind of Pd / TiO with amino modification 2 Preparation method of photocatalyst, including synthesis of TiO with {001} high-energy crystal faces 2 Nanosheets, APTMS Modification of TiO with {001} High Energy Crystal Plane 2 Nanosheets and Preparation of Pd / TiO 2 Photocatalyst three steps;

[0036] (1) Synthesis of TiO with {001} high-energy crystal plane 2 Nanosheets

[0037] Tetrabutyl titanate and hydrofluoric acid aqueous solution with volume percent concentration of 47% were placed in a polytetrafluoroethylene-lined autoclave, and the volume ratio of tetrabutyl titanate to hydrofluoric acid aqueous solution was 10:0.8, controlled The temperature was 180°C for hydrothermal reaction for 24 hours. After the reaction solution was washed with ethanol, 0.1M NaOH and deionized water in sequence, the obtained sample was vacuum-dried at 80°C, ground after drying, and then put into a muffle furnace for calcination at a controlled temperature of 400°C. 2h, through a 200-me...

Embodiment 3

[0043] A kind of Pd / TiO with amino modification 2 Preparation method of photocatalyst, including synthesis of TiO with {001} high-energy crystal faces 2 Nanosheets, APTMS Modification of TiO with {001} High Energy Crystal Plane 2 Nanosheets and Preparation of Pd / TiO 2 Photocatalyst three steps;

[0044] (1) Synthesis of TiO with {001} high-energy crystal plane 2 Nanosheets

[0045] Tetrabutyl titanate and hydrofluoric acid aqueous solution with volume percent concentration of 47% were placed in a polytetrafluoroethylene-lined autoclave, and the volume ratio of tetrabutyl titanate to hydrofluoric acid aqueous solution was 10:0.8, controlled The temperature was 180°C for hydrothermal reaction for 24 hours. After the reaction solution was washed with ethanol, 0.1M NaOH and deionized water in sequence, the obtained sample was vacuum-dried at 80°C, ground after drying, and then put into a muffle furnace for calcination at a controlled temperature of 400°C. 2h, through a 200-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com