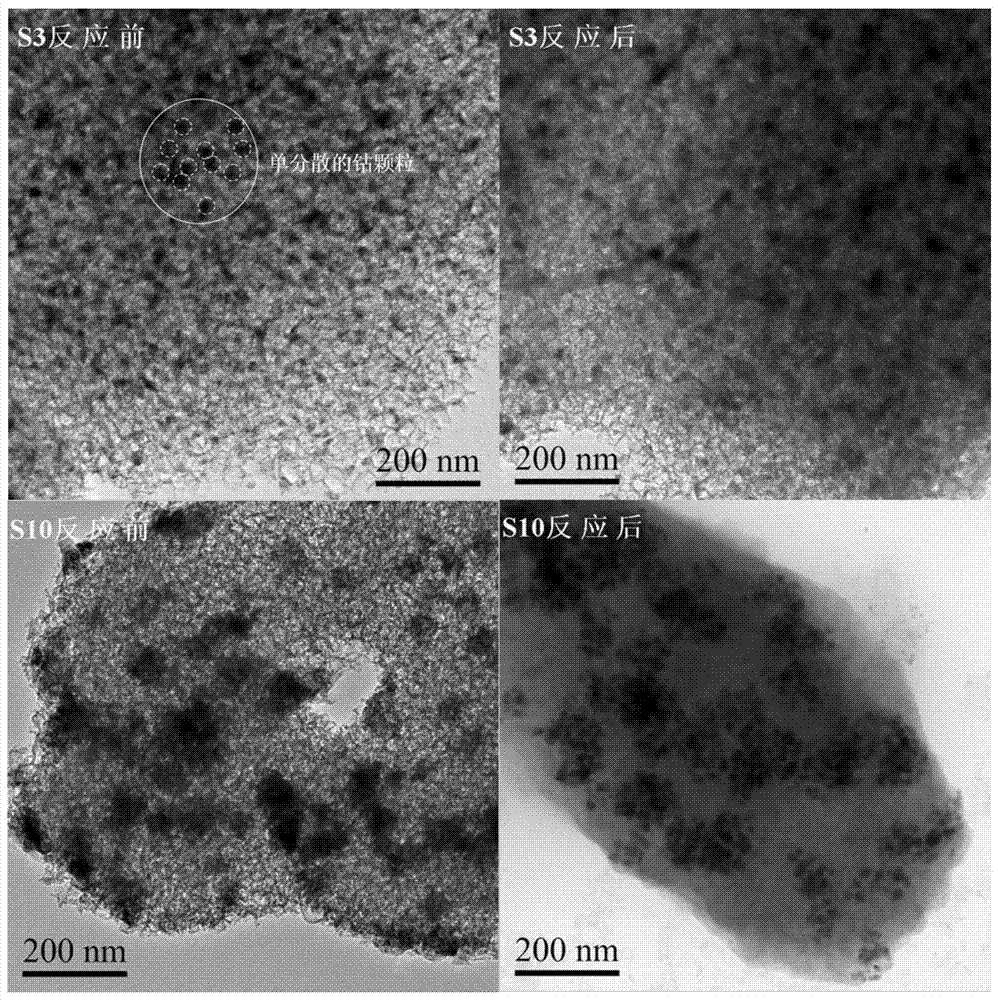

A preparation method of a particle-controllable and monodisperse cobalt-based Fischer-Tropsch synthesis catalyst

A cobalt-based Fischer-Tropsch synthesis technology, which is applied in the field of preparation of Fischer-Tropsch synthesis catalysts, can solve the problems of difficult sintering, poor dispersibility, and difficult control of cobalt crystal grains, and achieves hard carbon deposition, good stability, and hard deactivation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

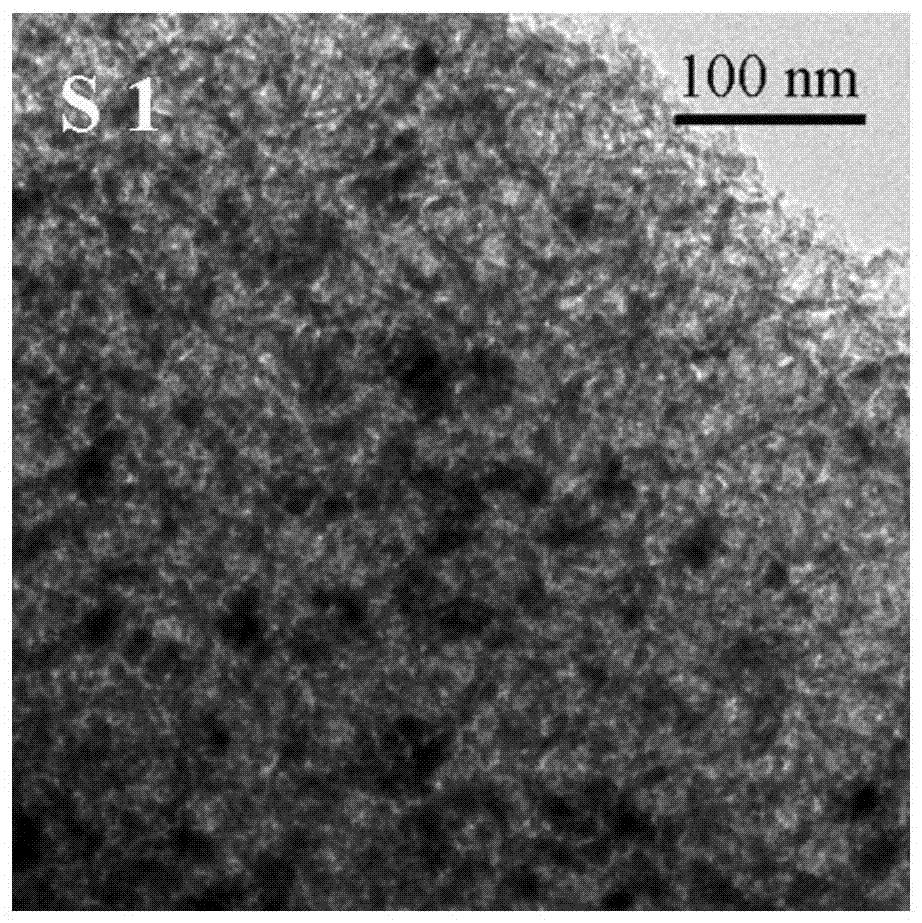

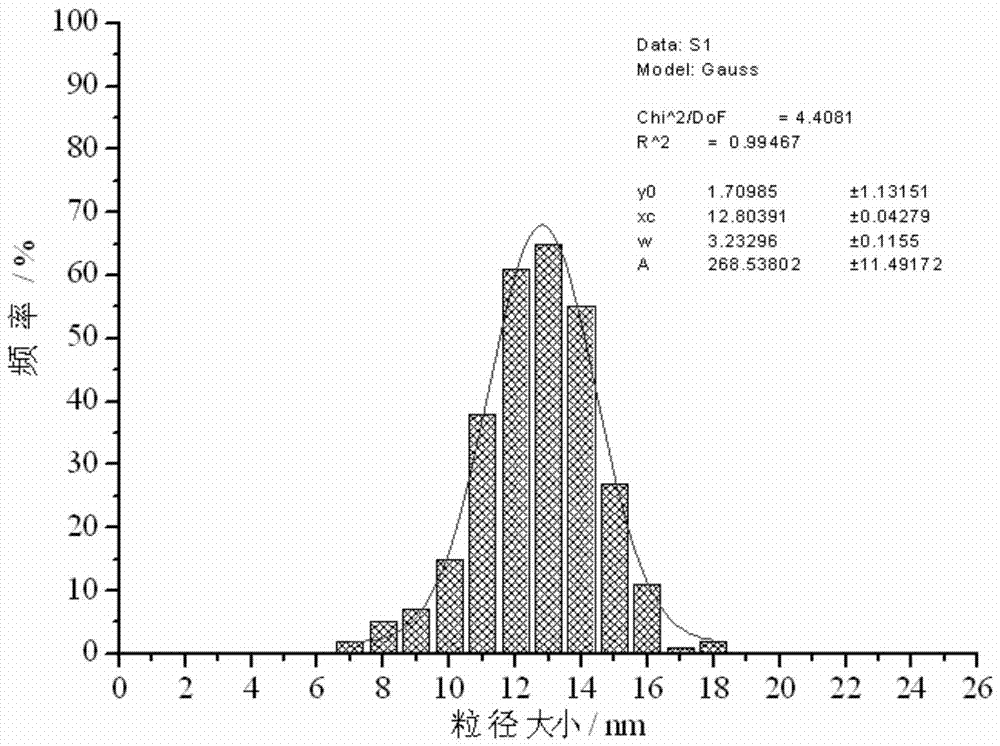

Embodiment 1

[0045] A kind of preparation method of 15Co / MCF-1 catalyst, its steps are as follows:

[0046] Get 2.0g silica mesoporous foam (specific surface area 654.6m 2 / g, small pore diameter 9.2nm, large pore diameter 45.1nm) baked in an oven at 100°C for 24h;

[0047] Mix 0.13g of absolute ethanol with 3.6g of distilled water, then add 0.04g of citric acid to obtain a mixed solution, then weigh 1.74g of cobalt nitrate and dissolve it in the above mixed solution to obtain a mixed solution containing cobalt sources;

[0048] Then, while rotating on the rotary evaporator, use a constant flow pump to evenly and slowly drop the mixed solution containing the cobalt source into the silicon oxide mesoporous foam. The rotating speed of the rotary evaporator is 80r / min. The mixed solution of the cobalt source was added dropwise in 70 minutes, therefore, the flow rate of the constant flow pump was 1.0ml / min. During the dripping process, when the carrier forms a large mass, stop the rotation a...

Embodiment 2

[0053] A kind of preparation method of 15Co / MCF-2 catalyst, its steps are as follows:

[0054] Get 2.0g silica mesoporous foam (specific surface area 654.6m 2 / g, small pore diameter 9.2nm, large pore diameter 45.1nm) baked in an oven at 100°C for 24h;

[0055] Mix 0.13g of absolute ethanol with 3.6g of distilled water, then add 0.8g of citric acid to obtain a mixed solution, then weigh 1.74g of cobalt nitrate and dissolve it in the above mixed solution to obtain a mixed solution containing cobalt sources;

[0056] Then, while rotating on the rotary evaporator, use a constant flow pump to evenly and slowly drop the mixed solution containing the cobalt source into the silicon oxide mesoporous foam. The rotating speed of the rotary evaporator is 80r / min. The mixed solution of the cobalt source was added dropwise in 70 minutes, therefore, the flow rate of the constant flow pump was 1.0ml / min. During the dripping process, when the carrier forms a large mass, stop the rotation an...

Embodiment 3

[0061] A kind of preparation method of 15Co / MCF-3 catalyst, its step is as follows:

[0062] Get 2.0g silica mesoporous foam (specific surface area 654.6m 2 / g, small pore diameter 9.2nm, large pore diameter 45.1nm) baked in an oven at 100°C for 24h;

[0063] Mix 0.13 g of absolute ethanol with 3.6 g of distilled water, then add 0.4 g of citric acid to obtain a mixed solution, then weigh 1.74 g of cobalt nitrate and dissolve in the above mixed solution to obtain a mixed solution containing cobalt sources;

[0064] Then, while rotating on the rotary evaporator, use a constant flow pump to evenly and slowly drop the mixed solution containing the cobalt source into the silicon oxide mesoporous foam. The rotating speed of the rotary evaporator is 80r / min. The mixed solution of the cobalt source was added dropwise in 70 minutes, therefore, the flow rate of the constant flow pump was 1.0ml / min. During the dripping process, when the carrier forms a large mass, stop the rotation and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com