Carbon nanotube, and preparation method and application thereof

A technology of carbon nanotubes and carbonates, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of low heteroatom doping amount and specific surface area, low catalytic activity of carbon nanotubes, and carbon doping The problem of low yield of nanotubes is to achieve the effect of simple process, suitable for continuous large-scale mass production, and enhanced electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Carbon nanotube provided by the invention, its preparation method, comprises the following steps:

[0030] (1) Carbon nanotubes are uniformly mixed with strong alkali or alkali metal carbonates so that the mass ratio of carbon nanotubes to strong alkalis or alkali metal carbonates is between 1:3 and 1:5 to obtain carbon A mixture of nanotubes and a strong base or a carbonate of an alkali metal; the strong base is preferably KOH or NaOH, and the carbonate of an alkali metal is preferably Na 2 CO 3 or K 2 CO 3 .

[0031] (2) heating the mixture obtained in step (1) to between 500°C and 900°C under the condition of cutting off oxygen, and calcining for 1 hour to 3 hours to obtain a calcined product;

[0032] (3) Washing and drying the calcined product obtained in step (2) to remove strong alkali or carbonate of alkali metal to obtain etched carbon nanotubes;

[0033] (4) Doping the etched carbon nanotubes obtained in step (3) with heteroatoms to obtain the carbon nano...

Embodiment 1

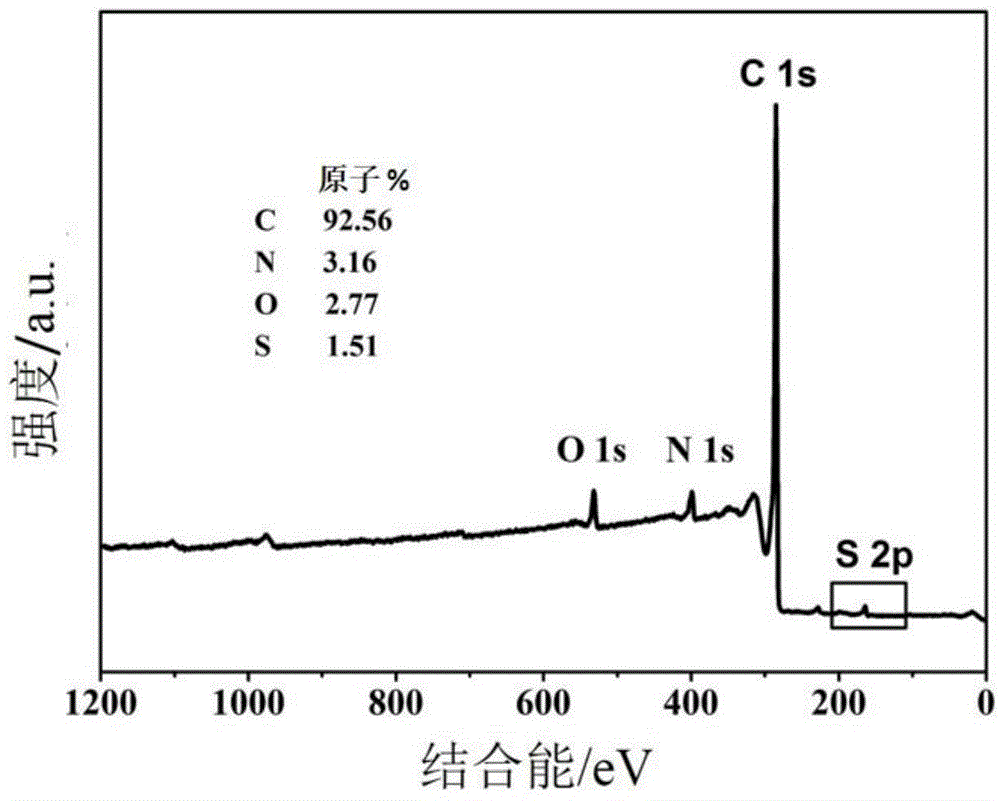

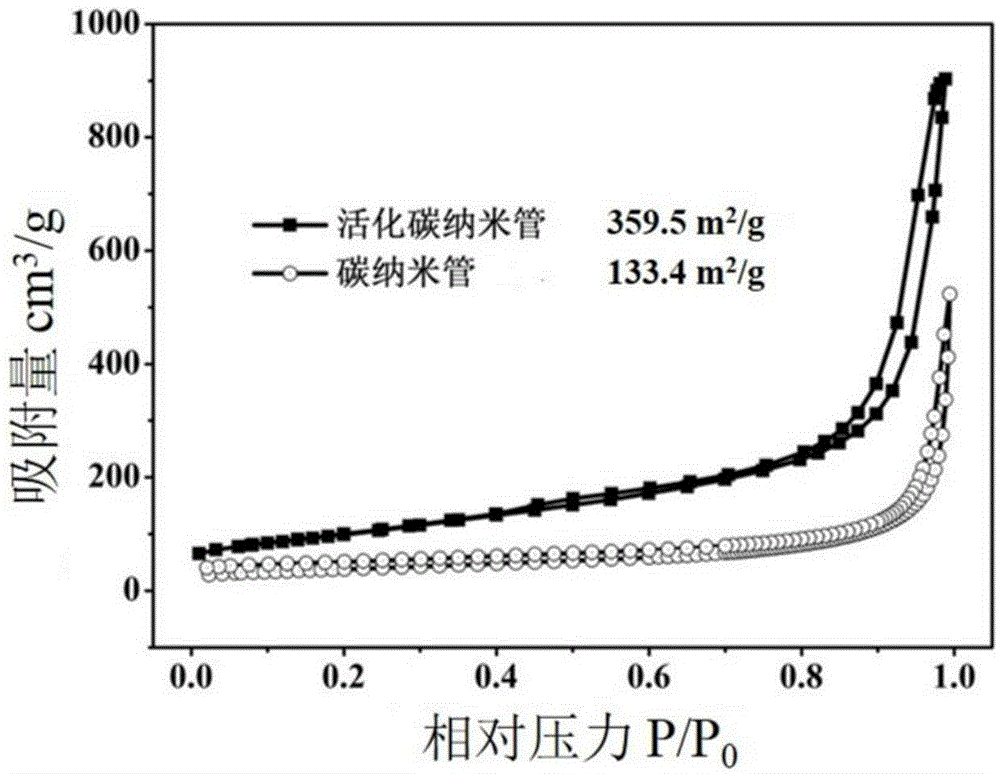

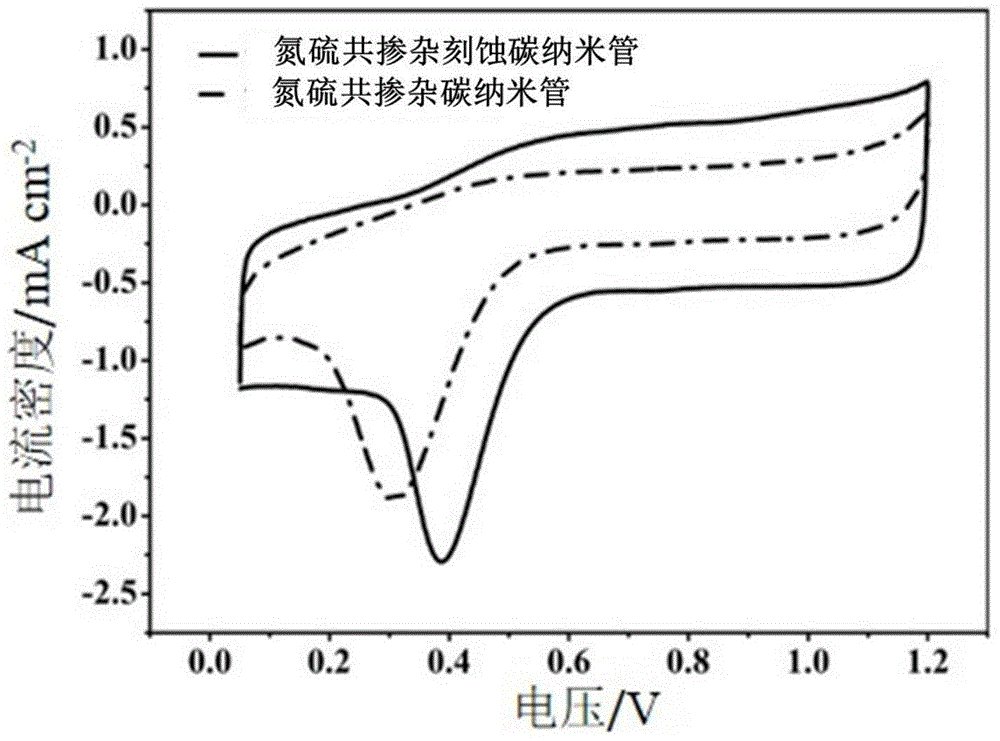

[0037] A carbon nanotube, a carbon nanotube doped with heteroatoms, X-ray photoelectron spectroscopy such as figure 1 As shown, wherein the mass ratio of heteroatoms is 4%, the surface of the carbon nanotube has a mesoporous structure, the average pore diameter of the mesopores is between 5nm, and the adsorption-desorption curve is as figure 2 As shown, the specific surface area of the carbon nanotubes is 369.5m 2 / g between. The heteroatoms are nitrogen atoms and sulfur atoms, wherein the nitrogen element is 3% and the sulfur element is 1% in terms of mass percentage.

[0038] The nitrogen atoms are doped in the form of pyridine nitrogen, pyrrole nitrogen and graphitized nitrogen. Sulfur atoms are doped in the form of carbon-sulfur single bonds (C-S-C) and carbon-sulfur double bonds (-C=S-).

[0039] Described carbon nanotube, its preparation method, comprises the following steps:

[0040] (1) Mixing the carbon nanotubes and NaOH evenly so that the mass ratio of the ca...

Embodiment 2

[0047] A carbon nanotube is a heteroatom-doped carbon nanotube, wherein the mass ratio of the heteroatom is 11%, the surface of the carbon nanotube has a mesopore structure, and the average pore diameter of the mesopore is 2nm, and the carbon nanotube The specific surface area is 1200m 2 / g between. The heteroatoms are nitrogen atoms and boron atoms, wherein the nitrogen element is 9% and the boron element is 2% in terms of mass percentage.

[0048] The nitrogen atoms are doped in the form of pyridine nitrogen, pyrrole nitrogen and graphitized nitrogen. Boron atoms are doped in the form of carbon-boron single bonds (C-B-C), oxygen-boron single bonds (O-B-C) and nitrogen-boron single bonds (N-B-C).

[0049] Described carbon nanotube, its preparation method, comprises the following steps:

[0050] (1) Mix the carbon nanotubes and KOH evenly so that the mass ratio of the carbon nanotubes and KOH is 1:5 to obtain a mixture of the carbon nanotubes and KOH.

[0051] (2) heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com