Diethylenetriamine derivatives, and preparation method and application thereof

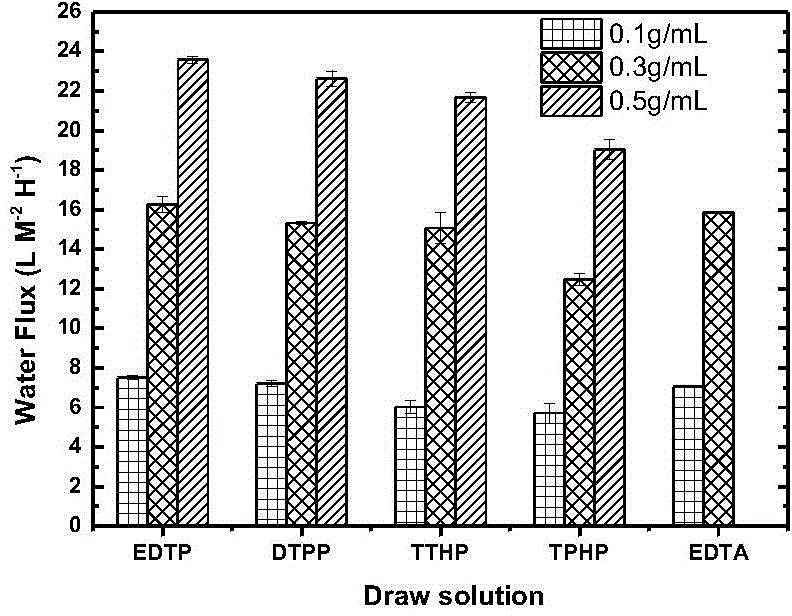

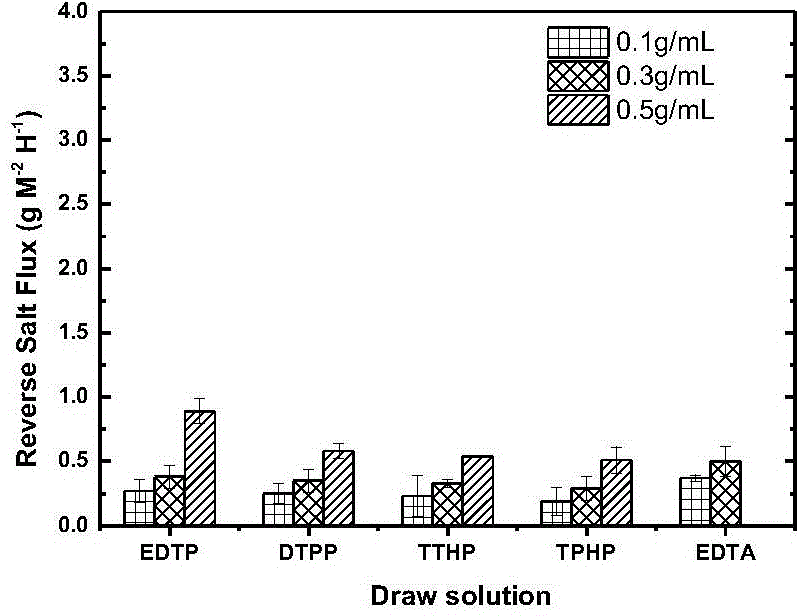

A technology of diethylenetriamine and derivatives, which is applied in the preparation of cyanide reaction, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of limited water flow and large salt flow, and achieve large water flux and high salt flow. Low flow, solve the effect of large salt flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

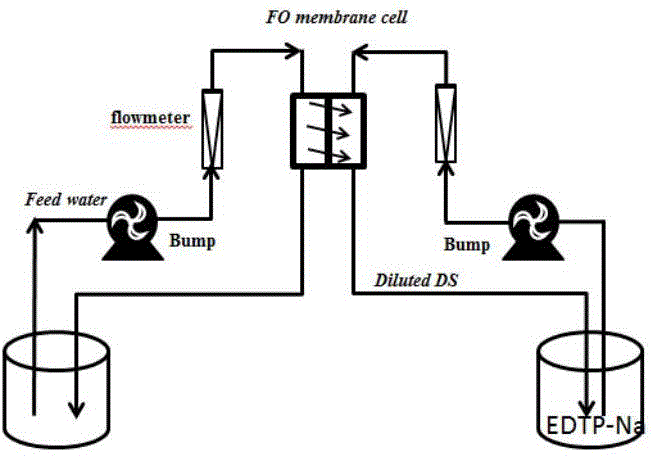

Method used

Image

Examples

Embodiment 1

[0051] A diethylenetriamine derivative is a diethylenetriamine derivative and sodium salt thereof shown in chemical formula (1) (see Table 1), prepared according to the following method:

[0052] (1) Under nitrogen atmosphere, mix diethylenetriamine, methyl acrylate and methanol evenly, keep the temperature of the mixture below 5°C, so that the molar ratio of diethylenetriamine, methyl acrylate and methanol is 1:10:12 , to obtain a mixed solution of diethylenetriamine and methyl acrylate. The temperature of the obtained mixed solution of diethylenetriamine and methyl acrylate was raised to 25°C, and reacted in the dark for 5 days, so that the mixed solution underwent Michael addition reaction, and the excess methyl acrylate and methanol solvent were removed by distillation under reduced pressure to obtain Mike Addition reaction product.

[0053] (2) The Mike addition reaction product obtained in step (1) is mixed with an aqueous solution of sodium hydroxide, so that the molar...

Embodiment 2

[0058] A diethylenetriamine derivative is a diethylenetriamine derivative and sodium salt thereof shown in chemical formula (2) (see Table 1), prepared according to the following method:

[0059] (1) Under a nitrogen atmosphere, mix ethylenediamine, methyl acrylate and methanol evenly, keep the temperature of the mixture below 5°C, so that the molar ratio of ethylenediamine, methyl acrylate and methanol is 1:8:12, and obtain A mixed solution of ethylenediamine and methyl acrylate. The obtained mixed solution of ethylenediamine and methyl acrylate was heated up to 20° C., and reacted in the dark for 1 day to cause the Michael addition reaction to occur in the mixed solution, and the excess methyl acrylate and methanol solvent were removed by distillation under reduced pressure to obtain the Michael addition reaction. into a reaction product.

[0060] (2) The Mike addition reaction product obtained in step (1) is mixed with an aqueous solution of sodium hydroxide so that the mo...

Embodiment 3

[0065] A diethylenetriamine derivative is a diethylenetriamine derivative and sodium salt thereof shown in chemical formula (3) (see Table 1), prepared according to the following method:

[0066] (1) Under nitrogen environment, mix triethylenetetramine, methyl acrylate and methanol evenly, keep the temperature of the mixture below 5°C, so that the molar ratio of triethylenetetramine, methyl acrylate and methanol is 1:12:10 , to obtain a mixed solution of triethylenetetramine and methyl acrylate. The temperature of the obtained mixed solution of triethylenetetramine and methyl acrylate was raised to 30° C., and reacted in the dark for 7 days to cause the Mike addition reaction to occur in the mixed solution, and the excess methyl acrylate and methanol solvents were distilled off under reduced pressure to obtain Mike Addition reaction product.

[0067] (2) The Mike addition reaction product obtained in step (1) is mixed with an aqueous solution of potassium hydroxide, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com