Hindered amine light stabilizer with characteristics of high molecular weight and narrow molecular weight distribution, and preparation method thereof

A high-molecular-weight, hindered amine technology, applied in the field of light stabilizers and their preparation, can solve the problems of inability to fully exert high-molecular-weight hindered amines, wide molecular weight distribution, etc., and achieve continuous and effective light stabilization, stable reaction, and simple process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

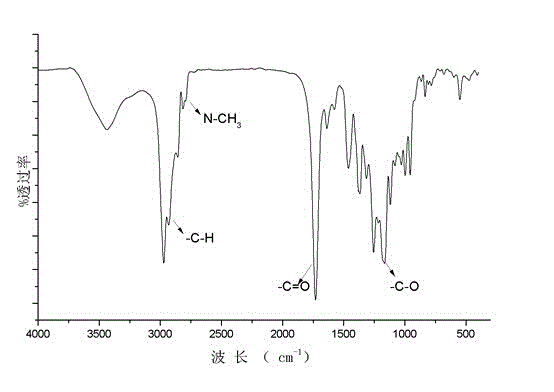

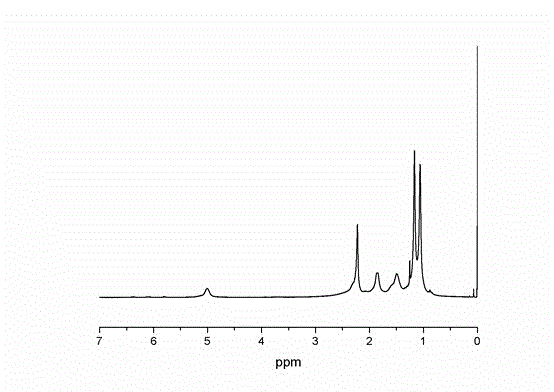

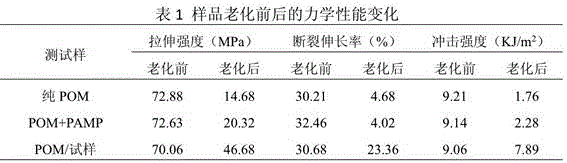

Method used

Image

Examples

Embodiment 1

[0031] 5.632 g of 4-acryloyloxy-1,2,2,6,6-pentamethylpiperidine, 0.0137 g of free radical initiator AIBN, RAFT chain transfer agent s,s'-bis(a,a'- Add 0.235 g of dimethyl acetic acid) trithiocarbonate into toluene, stir well, and fully dissolve; raise the reaction temperature to 70°C under the protection of nitrogen, and react for 12 hours. After the reaction is completed, use liquid nitrogen or ice water Perform quenching treatment; pour the obtained product mixture into methanol for precipitation treatment, filter with suction, wash with water, dry and wait until the final product. The number average molecular weight of the obtained product was 1326, and the molecular weight distribution index was 1.89.

Embodiment 2

[0033] 5.632 g of 4-acryloyloxy-1,2,2,6,6-pentamethylpiperidine, 0.025 g of free radical initiator AIBN, RAFT chain transfer agent s,s'-di(a,a'- Add 0.141 g of dimethyl acetic acid) trithiocarbonate into toluene, fully stir, and fully dissolve; under the protection of nitrogen, raise the reaction temperature to 70°C, and react for 12 hours. After the reaction is completed, use liquid nitrogen or ice water Perform quenching treatment; pour the obtained product mixture into methanol for precipitation treatment, filter with suction, wash with water, dry and wait until the final product. The number average molecular weight of the obtained product was 3450, and the molecular weight distribution index was 1.35.

Embodiment 3

[0035] 5.632 g of 4-acryloyloxy-1,2,2,6,6-pentamethylpiperidine, 0.103 g of free radical initiator AIBN, RAFT chain transfer agent s,s'-bis(a,a'- Add 0.352 g of dimethyl acetic acid) trithiocarbonate into toluene, fully stir and dissolve; raise the reaction temperature to 70°C under the protection of nitrogen, and react for 8 hours. After the reaction is completed, use liquid nitrogen or ice water Perform quenching treatment; pour the obtained product mixture into methanol for precipitation treatment, filter with suction, wash with water, dry and wait until the final product. The number average molecular weight of the obtained product was 1128, and the molecular weight distribution index was 2.21.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com