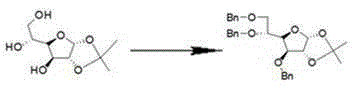

Method for preparing 3,5,6-tri-oxy-benzyl-1,2-isopropylidene-D-glucose

A technology of isopropylidene and glucose, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., to achieve the effects of simplifying the operation steps, avoiding the generation of by-product hydrogen, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

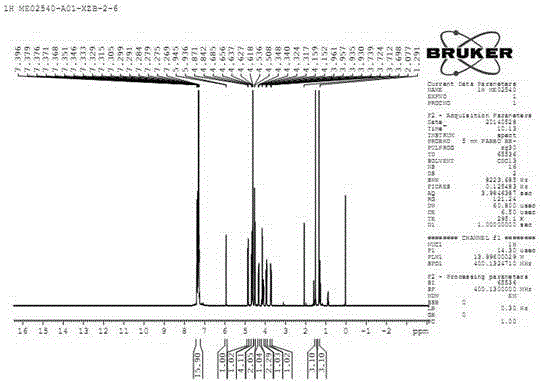

Image

Examples

Embodiment 1

[0018] Add 10g of 1,2-isopropylidene-D-glucose, 7g of sodium carbonate and 2g of tetrabutylammonium iodide into 40g of DMF, add 6g of benzyl bromide dropwise under stirring, and react at 20°C for 20h after the dropwise addition , after the reaction was completed, filtered, concentrated under reduced pressure at 100°C, and the residue was purified by column chromatography, eluting with ethyl acetate:petroleum ether=1:7, and concentrated under reduced pressure to remove the solvent to obtain 3,5,6-tri- Oxy-benzyl-1,2-isopropylidene-D-glucose 19.69g, yield 89.5%.

Embodiment 2

[0020] Add 10g of 1,2-isopropylidene-D-glucose, 5g of sodium carbonate and 1g of tetrabutylammonium iodide into 30g of DMF, add 2g of benzyl bromide dropwise under stirring, and react at 0°C for 20h after the dropwise addition , after the reaction was completed, filtered, concentrated under reduced pressure at 100°C, and the residue was purified by column chromatography, eluting with ethyl acetate:petroleum ether=1:7, and concentrated under reduced pressure to remove the solvent to obtain 3,5,6-tri- Oxy-benzyl-1,2-isopropylidene-D-glucose 19.56g, yield 88.9%.

Embodiment 3

[0022] Add 10g of 1,2-isopropylidene-D-glucose, 5g of sodium hydroxide and 4g of tetrabutylammonium iodide into 30g of DMF, add 8g of benzyl bromide dropwise under stirring, and react at 50°C after the addition is complete 30h, after the reaction is completed, filter, concentrate under reduced pressure at 100°C, and purify the residue by column chromatography, eluting with ethyl acetate:petroleum ether=1:7, and remove the solvent by concentrating under reduced pressure to obtain 3,5,6-tri -Oxy-benzyl-1,2-isopropylidene-D-glucose 19.62 g, yield 89.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com