Preparation method of PA6 (polyamide 6)/PP (polypropylene)/carbon nano tube high-performance nano composite material

A nanocomposite material and carbon nanotube technology, which is applied in the field of preparation of polyamide 6/polypropylene/carbon nanotube high-performance nanocomposite materials, can solve problems such as poor dimensional stability, application limitations, and high water absorption. Achieve high tensile strength and flexural strength, performance improvement, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

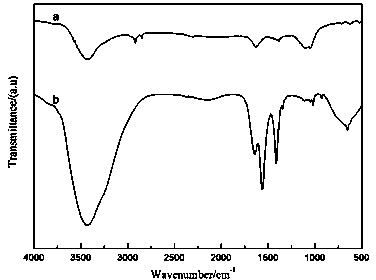

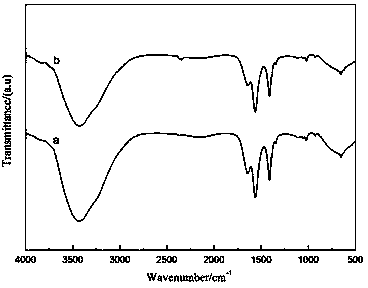

Image

Examples

Embodiment 1

[0025] 1) Coating silica by sol-gel method: In a 500 mL beaker, add 2.0 g of dry carbon nanotubes and 200 mL of an aqueous solution containing 0.5 wt% sodium dodecylsulfonate, and disperse with 80 kHz ultrasonic waves 2 h. The obtained solution is filtered by a Buchner suction filtration device, washed three times with deionized water, and excess sodium dodecylsulfonate not coated on the surface of the carbon nanotubes is removed to obtain surfactant-treated carbon nanotubes. Under the action of ultrasonic waves, the surfactant-treated carbon nanotubes are redispersed in deionized water to obtain a uniformly dispersed carbon nanotube aqueous solution. According to the volume ratio of 5:1, the aqueous solution of carbon nanotubes was added to the mixed solution of ethyl orthosilicate, deionized water and absolute ethanol (the weight ratio of ethyl orthosilicate, deionized water and absolute ethanol The ratio is 2:1:4). The obtained mixed solution was ultrasonically treated fo...

Embodiment 2

[0029]The mass ratio of PP and PA6 is 70:30, and other conditions are the same as in Example 1, which is recorded as PP / PA6. Experiments show that the tensile strength of PP / PA6 is 31.06 MPa, and the bending strength is 50.02 MPa.

Embodiment 3

[0031] The mass ratio of PP, PA6, PP-g-MAH is 70:30:5, and other conditions are the same as in Example 1, which is recorded as PP / PA6 / 5M. Experiments show that the tensile strength of PP / PA6 / 5M is 38.89MPa, The bending strength is 54.42MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com